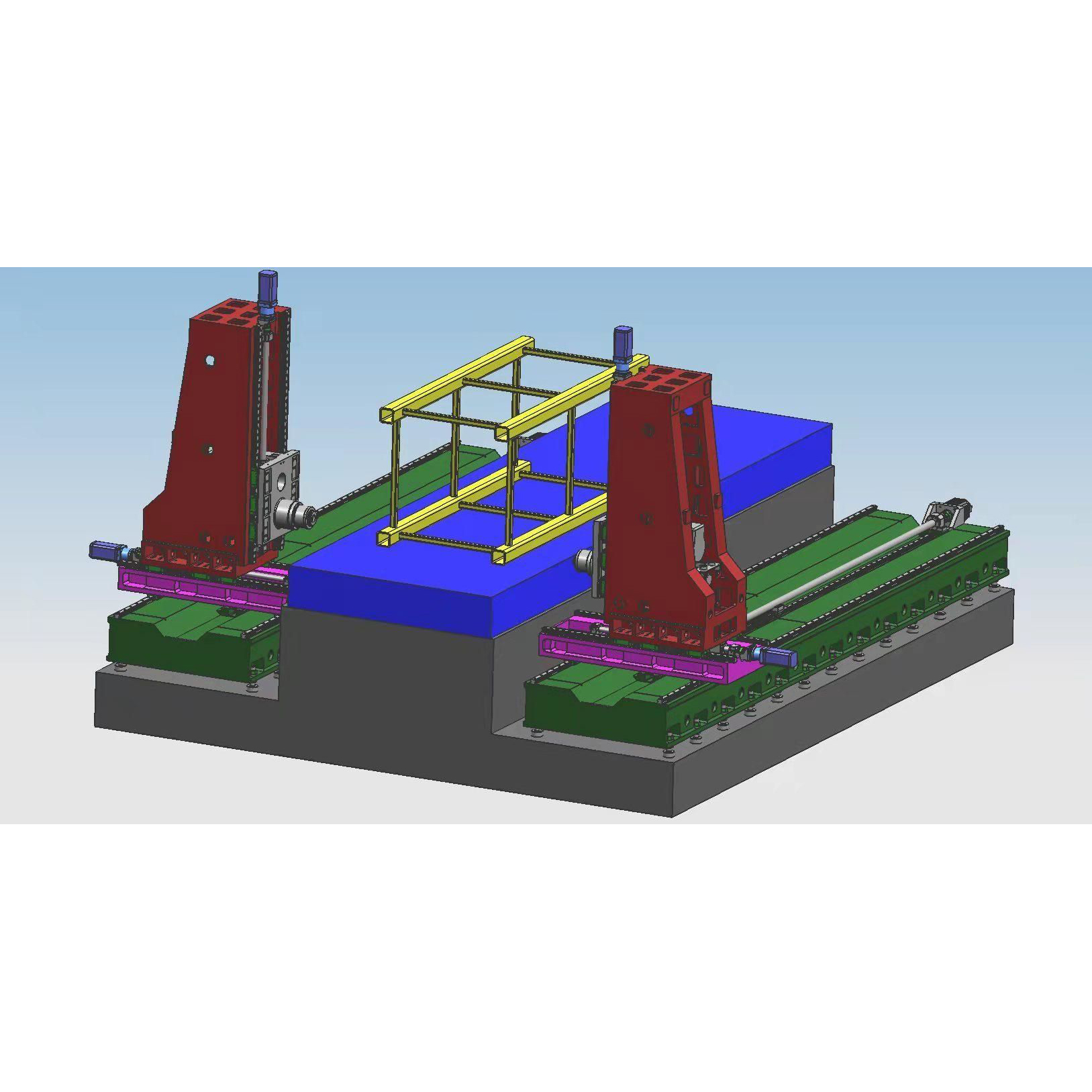

Cnc Deep Hole Drilling Machine Manufacturer in China - High Quality Solutions

When it comes to precision and efficiency, our CNC Deep Hole Drilling Machine stands out in the market. As a manufacturer based in China, I’m proud to offer solutions that enhance productivity for your business. This machine is designed for deep hole drilling, ensuring clean, accurate holes with every pass. Our commitment to quality means you can rely on the durability and performance of our equipment. Whether you're in the aerospace, automotive, or energy sectors, it can handle a range of materials with precision. With user-friendly controls and advanced technology, it’s perfect for both seasoned professionals and those new to CNC machining. I invite you to elevate your manufacturing capabilities with our top-tier machines, tailored to meet the demands of modern industry. Let’s work together to achieve your production goals with cutting-edge technology and unmatched support.

Cnc Deep Hole Drilling Machine For the Current Year Factory-Direct Excellence

In the rapidly evolving landscape of manufacturing technology, the demand for precision and efficiency is at an all-time high. The Cnc Deep Hole Drilling Machine has emerged as a pivotal tool for industries requiring intricate drilling capabilities for various applications, including aerospace, automotive, and mold making. As companies look to optimize their operations while maintaining high-quality standards, investing in factory-direct excellence has become a strategic approach to ensuring reliability and performance. One of the most compelling advantages of acquiring a CNC deep hole drilling machine directly from the manufacturer is the assurance of quality control throughout the production process. By eliminating intermediaries, buyers can gain insights into the manufacturing practices and materials used, ensuring that they receive a product that meets rigorous performance criteria. This direct relationship can also facilitate customized solutions tailored to specific operational needs, enhancing productivity and reducing lead times. Moreover, as businesses strive for cost efficiency, factory-direct purchases often come with reduced pricing due to the absence of added markups. This enables companies to allocate resources more effectively while investing in advanced machinery that provides a competitive edge. As industries globally continue to prioritize innovation and sustainability, the adoption of state-of-the-art machining technology will play a crucial role in driving operational success and meeting the demands of an increasingly sophisticated market.

Cnc Deep Hole Drilling Machine For the Current Year Factory-Direct Excellence

| Model | Max Drilling Depth (mm) | Drilling Diameter (mm) | Spindle Motor Power (kW) | Control System | Weight (kg) |

|---|---|---|---|---|---|

| DH-1000 | 1000 | 10-50 | 15 | CNC Controller A | 1200 |

| DH-2000 | 2000 | 15-70 | 18 | CNC Controller B | 1500 |

| DH-3000 | 3000 | 20-80 | 22 | CNC Controller C | 2000 |

| DH-4000 | 4000 | 25-90 | 30 | CNC Controller D | 2500 |

Related Products