Special CNC Machine for Valve | Leading Manufacturer in China

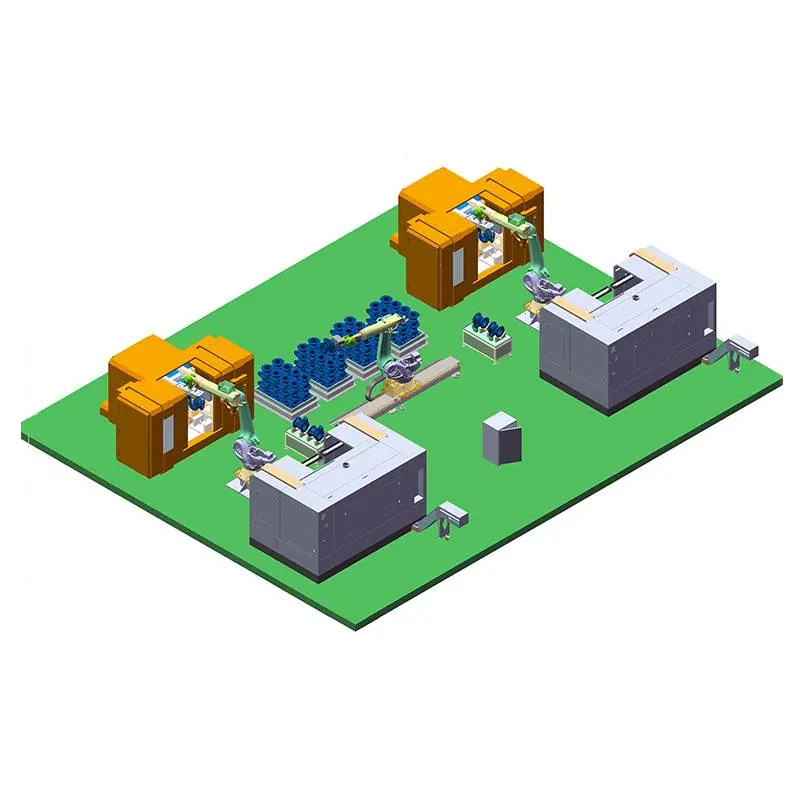

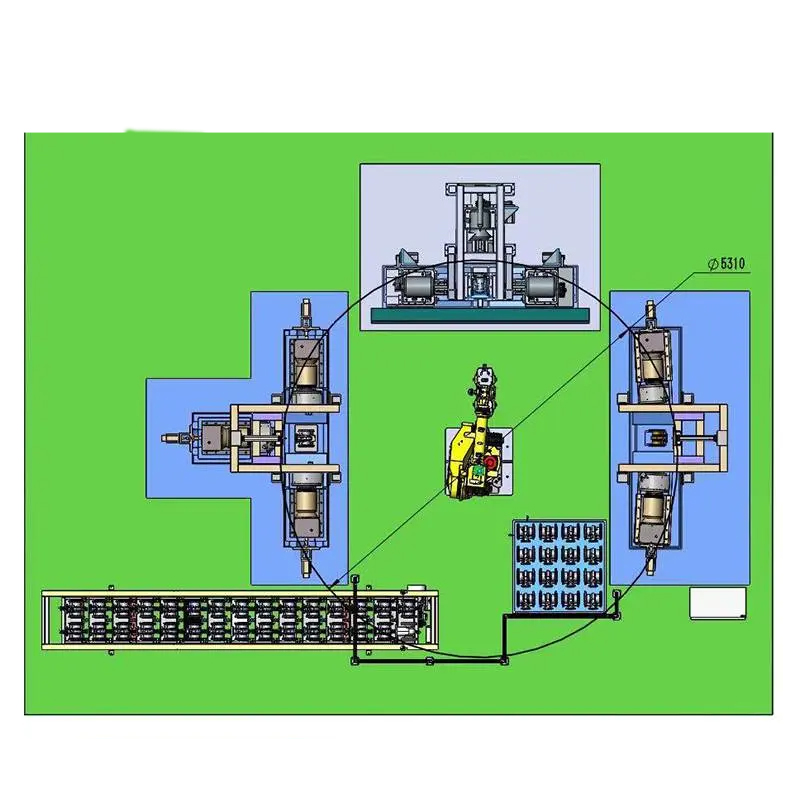

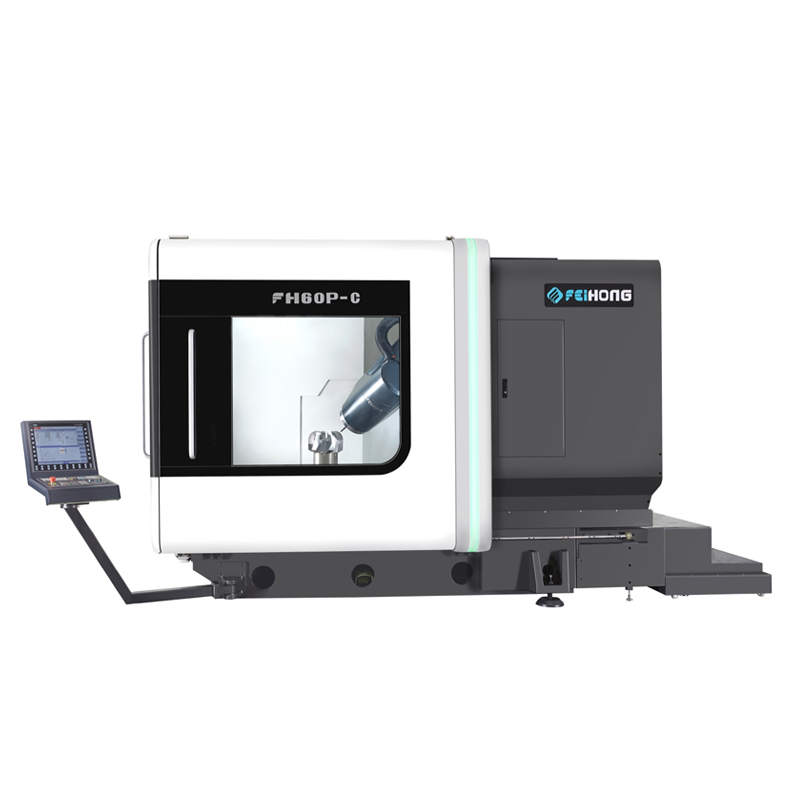

When it comes to precision engineering, our special CNC machine for valves stands out in the market. As a seasoned manufacturer in China, we understand the intricacies needed for producing high-quality valves. This machine is designed for efficiency, allowing for tight tolerances and intricate designs that are essential in valve manufacturing. With our state-of-the-art technology, you can expect exceptional reliability and performance, reducing waste and increasing production rates. We pride ourselves on providing solutions tailored to your needs, whether you’re dealing with a small batch or large-scale production. Choosing our special CNC machine means partnering with a manufacturer that values your time and resources. Let us help you streamline your production processes and elevate the quality of your valves. Reach out today to learn more about how our machine can make a difference in your business!

Special Cnc Machine For Valve Dominates Supplies the World\u2019s Top Brands

In the ever-evolving landscape of industrial manufacturing, the demand for precision and efficiency continues to rise, particularly in valve production. Special CNC machines designed for valve manufacturing have emerged as essential tools, providing unparalleled accuracy and maximizing productivity. These machines cater to the intricate demands of the valve industry, making it possible to produce complex components that meet the highest quality standards. By automating critical processes, manufacturers can not only reduce lead times but also enhance the consistency of their products, which is vital for maintaining competitive edge. For global buyers seeking reliable solutions, investing in specialized CNC machinery offers a pathway to streamline operations and achieve remarkable cost-efficiency. These advanced machines harness cutting-edge technology to support varying production scales, from small batch needs to large-scale manufacturing. Enhanced features such as user-friendly interfaces and real-time monitoring contribute to a seamless operational experience, allowing companies to adapt quickly to market changes and customer demand. Moreover, embracing such technologically advanced machinery signifies a commitment to innovation and sustainability. By minimizing waste and optimizing energy consumption, manufacturers can meet both their production goals and environmental responsibilities. As the valve industry continues to grow, leveraging advanced CNC machines will be crucial for players aiming to establish a footprint in the global market, ultimately leading to enhanced product quality and reinforced brand reputation.

Special CNC Machine For Valve Dominates Supplies the World’s Top Brands

| Feature | Description | Applications | Materials Compatible | Country of Supply |

|---|---|---|---|---|

| Precision Machining | High accuracy in valve component fabrication | Oil & Gas, Water Treatment | Stainless Steel, Brass | USA, Germany |

| Automated Production | Enhanced efficiency and reduced labor costs | Manufacturing, Aerospace | Aluminum, Titanium | China, Japan |

| Custom Design | Tailored solutions for specific valve needs | Hydrocarbon Processing, HVAC | Carbon Steel, Copper | Italy, South Korea |

| Advanced Technology | Incorporation of IoT for real-time monitoring | Energy Sector, Pharmaceuticals | Composite Materials, Plastics | Canada, Brazil |

Related Products