CNC Tube Sheet Drilling Machine Manufacturer in China - Quality Solutions

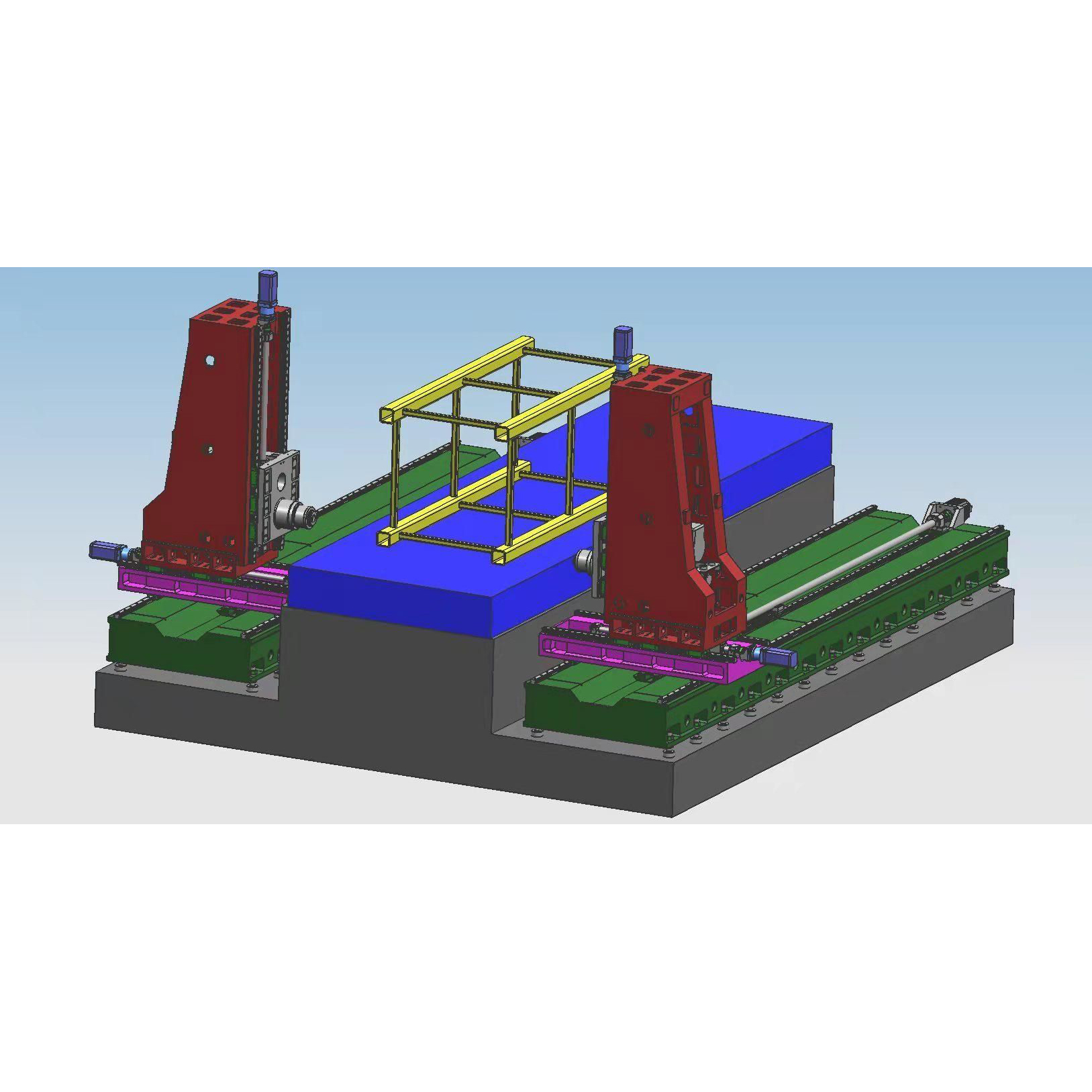

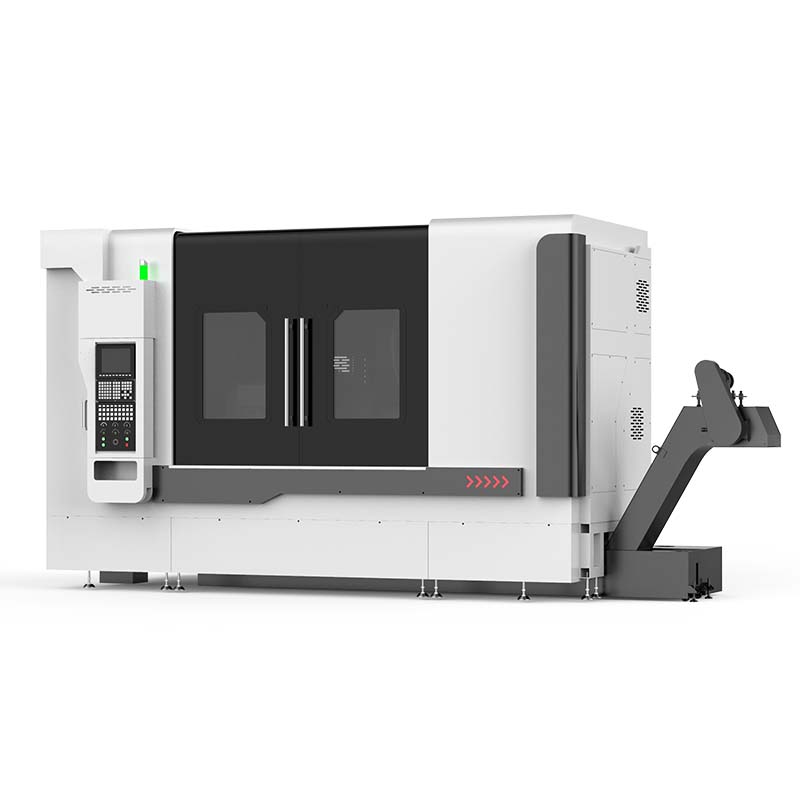

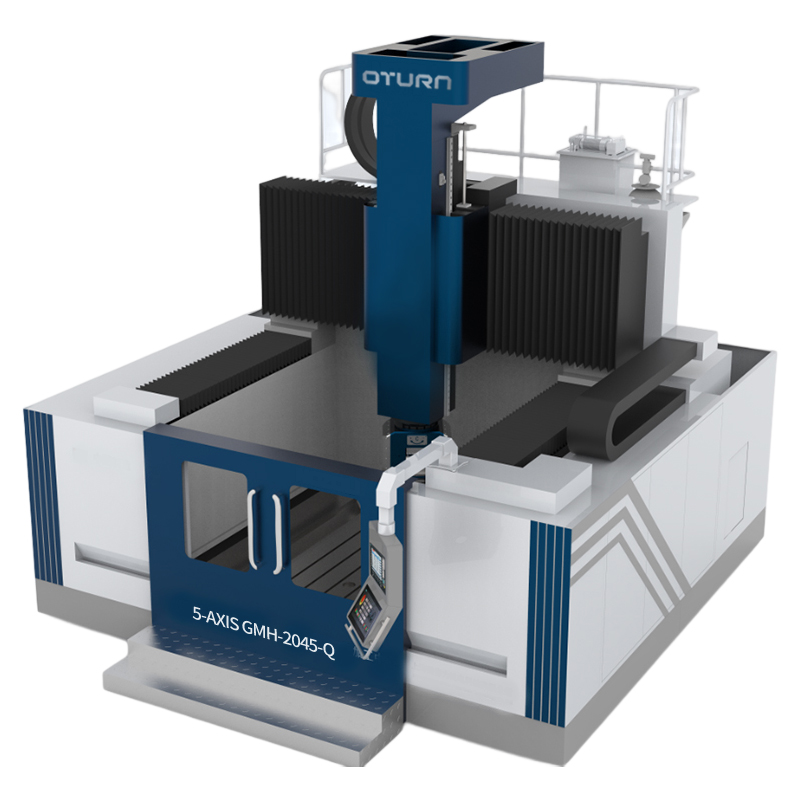

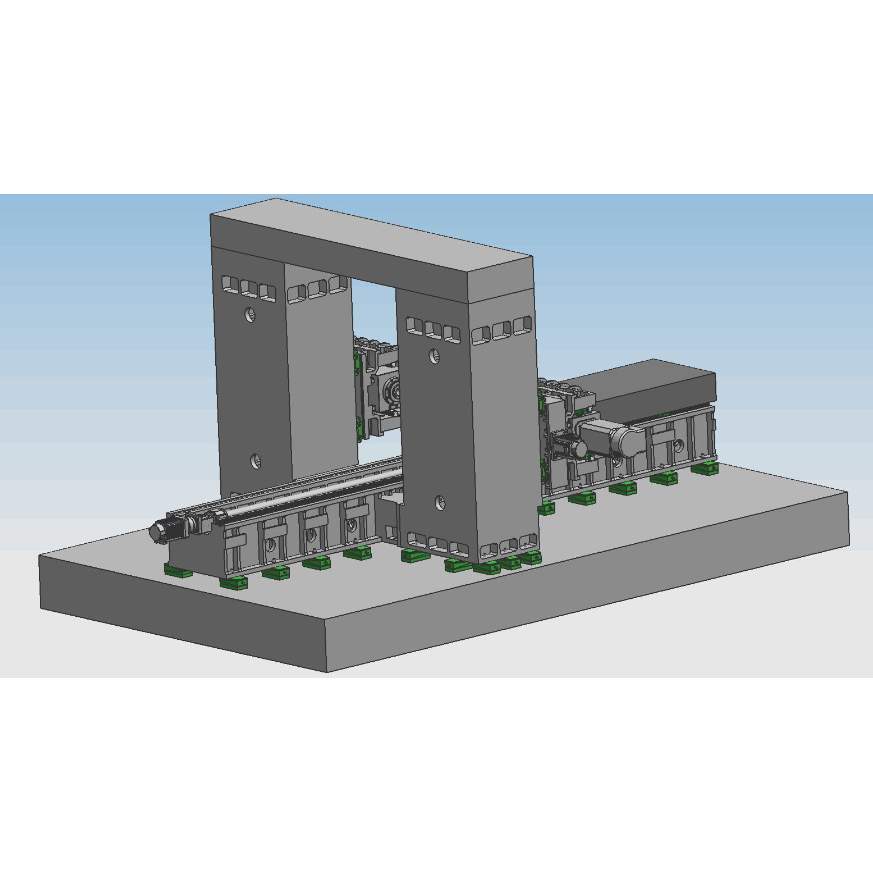

When it comes to precision and efficiency, our CNC Tube Sheet Drilling Machine stands out in the market. As a dedicated manufacturer based in China, I’ve witnessed firsthand the transformation this machine brings to manufacturing processes. With its advanced technology, it effortlessly handles various tube sheet drilling tasks, ensuring accuracy and durability that your business needs. I know that time and cost efficiency is crucial for B2B purchasers, and this machine optimizes both. Its user-friendly interface allows for quick adjustments, making it ideal for both small and large-scale projects. Additionally, the robust build means it’s ready to tackle even the most demanding work. Whether you’re looking to increase production rates or maintain tight tolerances, our CNC Tube Sheet Drilling Machine can elevate your operations. I’m here to help you make the right choice for your business needs, so let’s connect and explore how this machinery can drive your success!

Cnc Tube Sheet Drilling Machine Factory Dominates

In the competitive landscape of manufacturing, efficiency and precision are paramount—especially when it comes to CNC tube sheet drilling machines. A leading factory has emerged to set the standard for quality and innovation in this sector. This establishment is renowned for producing equipment that not only meets but exceeds the rigorous demands of global buyers seeking reliable solutions for tube sheet processing. The CNC tube sheet drilling machines offered are engineered with cutting-edge technology to enhance productivity and accuracy. Features such as automated drilling, user-friendly interfaces, and real-time monitoring systems address the key challenges faced by manufacturers in various industries. As buyers increasingly look for reliable machinery that can handle diverse applications, these machines stand out for their versatility and robustness, ensuring they can tackle projects of varying complexity with ease. For global procurement professionals, partnering with a top-tier manufacturing facility means gaining access to advanced machinery that can significantly streamline operations and maximize output. The commitment to quality control and customer satisfaction is evident in every aspect of the production process, making these machines not just an investment in equipment, but a strategic move toward achieving superior operational efficiency and competitive advantage in the marketplace.

Cnc Tube Sheet Drilling Machine Factory Dominates

| Feature | Specification | Application | Efficiency |

|---|---|---|---|

| Drilling Speed | 1000 RPM | Tube Manufacturing | High |

| Maximum Drill Diameter | 25 mm | Automotive Parts | Medium |

| Control System | CNC | Construction Industry | Very High |

| Power Supply | 220V/380V | Heavy Machinery | High |

| Weight | 500 kg | General Manufacturing | Medium |

Related Products