Cnc Plate Drilling Machine Manufacturer in China - Quality & Precision

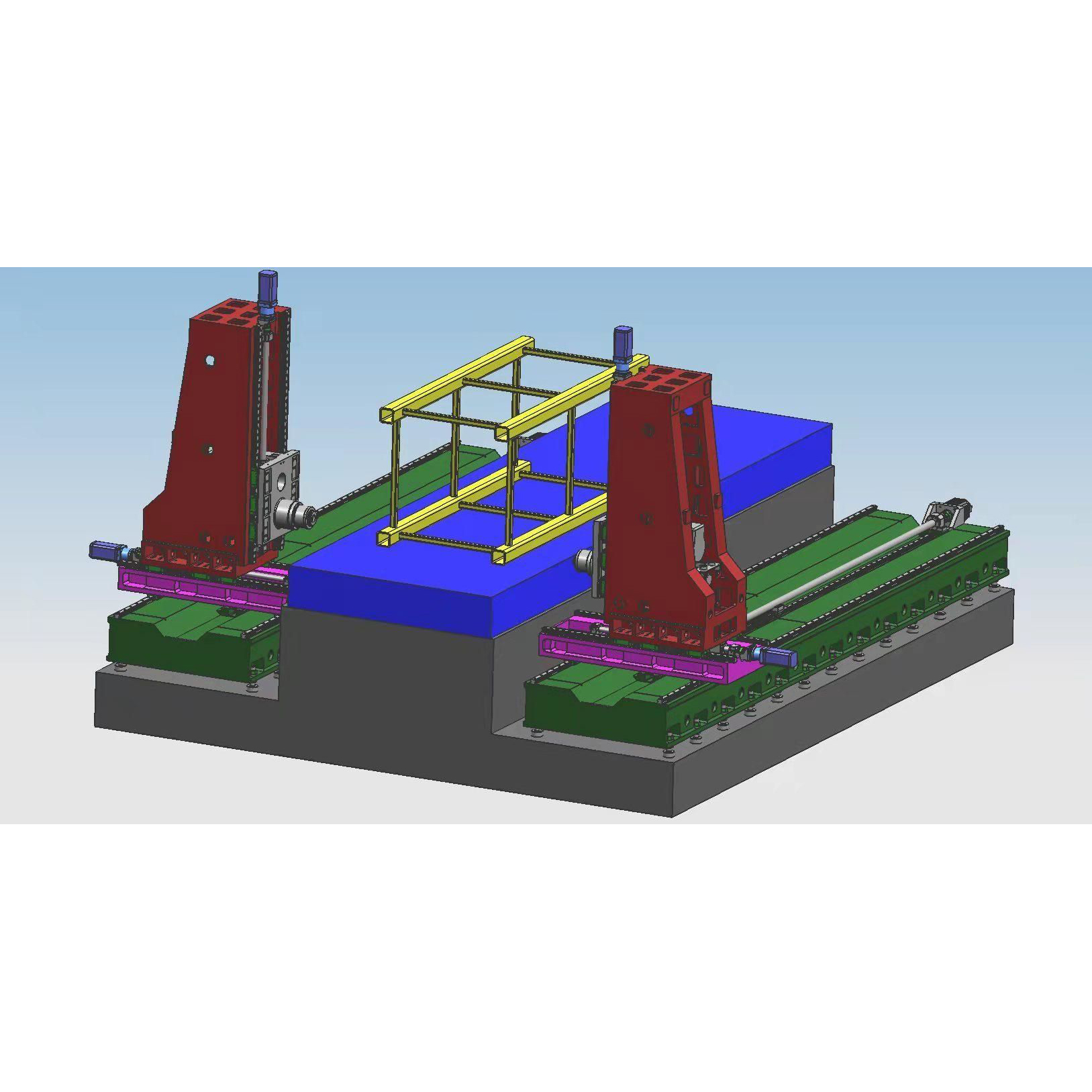

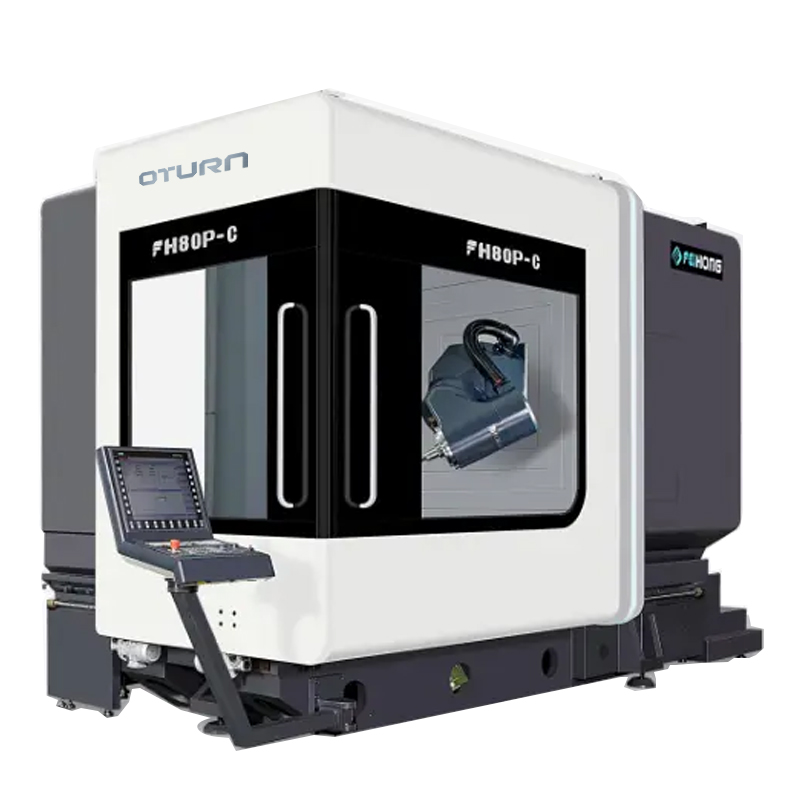

As a professional in the field, I know how crucial precision and efficiency are for your operations. Our CNC Plate Drilling Machine, manufactured in China, offers advanced technology designed to meet the rigorous demands of today’s industry. With robust construction and user-friendly controls, this machine ensures accurate drilling with minimal downtime. I understand that sourcing reliable equipment is essential for your productivity. That’s why our equipment is not only competitively priced but also built to last, providing excellent value over its lifecycle. We prioritize quality and consistency, so you can trust our machines to deliver exceptional results every time. Whether you’re a small business or a large manufacturer, this CNC Plate Drilling Machine is designed to enhance your workflow and boost your output. Don’t miss the chance to elevate your manufacturing process with a trusted solution from a leading China manufacturer. Let’s connect to discuss how we can support your needs!

Cnc Plate Drilling Machine For the Current Year Your End-to-End Solution

In today's competitive manufacturing landscape, the demand for precision and efficiency has never been higher, particularly in the metalworking industry. The CNC plate drilling machine stands out as an essential tool for enhancing production capabilities and ensuring high-quality results. This year, these machines have been engineered with advanced technology that integrates automation, precision drilling, and user-friendly interfaces, making them an ideal investment for businesses aiming to streamline their operations and improve productivity. Purchasing a CNC plate drilling machine is not just about acquiring machinery; it's about adopting a comprehensive solution that addresses various operational needs. These machines are designed to handle diverse materials and plate sizes while maintaining accuracy and speed. Their end-to-end capabilities allow manufacturers to reduce setup times and material waste, ultimately leading to increased profitability. By investing in state-of-the-art technology, companies can meet the evolving demands of their clients, offering them faster turnaround times and superior products. Moreover, with the ongoing advancements in CNC technology, buyers can expect features like real-time monitoring and analytics, enhanced safety mechanisms, and remote operation capabilities. These innovations not only improve operational efficiency but also ensure compliance with international quality standards, making CNC plate drilling machines an ideal choice for global buyers seeking reliable and high-performance solutions for their manufacturing needs.

Cnc Plate Drilling Machine For the Current Year Your End-to-End Solution

| Model | Drilling Capacity (mm) | Spindle Speed (RPM) | Max Plate Size (mm) | Weight (kg) |

|---|---|---|---|---|

| Model A | 30 | 3000 | 1000 x 2000 | 1500 |

| Model B | 25 | 2500 | 1200 x 2500 | 1600 |

| Model C | 35 | 3200 | 1500 x 3000 | 1700 |

| Model D | 40 | 3500 | 2000 x 4000 | 1800 |

Related Products