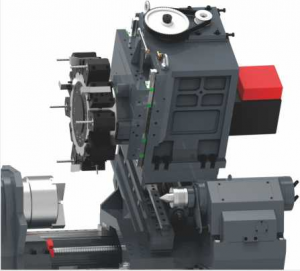

CNC Turn-Milling Combined Machine

INTEGRATED POSITIVEYAXIS

Longmen structure, super rigid

Integrated positive Y axis structure belongs to high-rigidity heavy cutting and its performance is better than the interpolation Y axis.

a. Single Y axis motion heavy cutting is better than interpolation Y axis and the Y axis is perpendicular to the X axis.

b. The plane contour processing is smoother and flatter.

c. More convenient for compound surface and contour processing.

"Positive Y" turn-milling combined equipment has obvious advantages in machining plane milling compared with "interpolation Y" turn-milling combined.The movement of the "Positive Y" Y-axis is perpendicular to the X-axis, which is a single-axis movement and the "interpolation Y" Y-axis movement is to interpolate a straight line through the simultaneous movement of X-axis and Y-axis,the flatness of the milling plane and the comparison of the “positive Y" axis turn-milling combined,"Positive Y" axis turn-milling combined processing is obviously bright and flat.

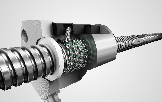

Double fixed ball screw

High-quality ball screws and roller guides from top global manufacturers are used.

Although expensive, only high-quality products can meet the high precision and long

service life required by customers.

Direct-Coulled Servomotors

The servo motor is directly connected to the ball screw via a steel coupling, which

ensures no degeneration and misalignment even under heavy loads.

This will greatly improve positioning accuracy, and thread and contour machining

will be more accurate.

106M 108M 208M

| ltem Model | Name | Unit | 106MY | 108MY | 208MY |

| Travel | Max. Turning Diameter on the Bed | mm | φ600 | φ600 | φ600 |

| Max. Processing Diameter | mm | φ320 | φ300 | φ400 | |

| Max . Processing Diameter on the Tool Holder | mm | φ220 | φ220 | φ380 | |

| Max. Processing Length | mm | 250 | 250 | 370 | |

| Distance Between Centers | mm | 380 | 380 | 600 | |

| Spindle Motor Hydrocylinder Chuch Parameter |

Spindle Nose | type | A2-5 | A2-6 | A2-6 |

| Max . Speed of Spindle | rpm | 5500 | 4300 | 4200 | |

| Oil Cylinder/ Chuck | lnch | 6” | 8” | 8” | |

| Spindle Bore | mm | φ56 | φ65 | φ65 | |

| Bar Diameter | mm | φ45 | φ52 | φ52 | |

| Direct Drive Spindle Motor Power | kw | 17.5 | 22 | 22 | |

| X/Z/Y Axis Feed Parameter |

X Travel | mm | 180 | 180 | 280 |

| X/Z Linear Guide Specification | spes | 35/35Rolller | 35/35Rolller | 35/35Rolller | |

| Z Travel | mm | - | 300 | 600 | |

| X/Z/Y Motor Power | kw | 1.8/1.8/1.0 | 1.8/1.8/1.0 | 1.8/1.8/1.0 | |

| X/Z//Y Rapid Traverse | m/min | 30/30/10 | 30/30/10 | 20/20/10 | |

| Positioning Accuracy | mm | ±0.005 | ±0.005 | ±0.005 | |

| Repeat Positioning Accuracy | mm | ±0.003 | ±0.003 | ±0.003 | |

| Turret Parameter | Tool Position | pcs | BMT45-12T | BMT45-12T | BMT55-12T |

| Power Turret Motor | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| Square Tool Holder | mm | 20×20 | 20×20 | 20×20 | |

| Round Boring Tool Holder | mm | φ32 | φ32 | φ40 | |

| Adjacent Tool Change Time | sec | 0.15 | 0.15 | 0.15 | |

| Positioning Accuracy | / | ±2” | ±2” | ±2” | |

| Repeat Positioning Accuracy | / | ±1” | ±1” | ±1” | |

| Tailstock Parameters |

Programmable Hydraulic Tailstock | / | √ | √ | |

| Max . Travel of Tailstock | mm | 360 | 360 | 440 | |

| Tailstock Sleeve Taper Hole | type | MT 5# | MT 5# | MT 5# | |

| Sleeve Diameter | mm | / | / | / | |

| Sleeve Travel | mm | / | / | / | |

| Mechanical Size | Machine Size | mm | 2300×1800×1700 | 2300×1800×1700 | 2620×2200×1920 |

| Machine Weight | kg | 3700kg | 3800kg | 5200kg |

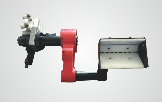

Servo Automatic Bar Feeder

TENOLY feeders feature a heavy-duty and automated design,

It significantly increases productivity and simplifies turning operations.

Parts Catcher

The workpiece catcher is designed with the principle of mechanical linkage, which can be quickly

connected with the finished product after processing.

THK roller linear guide

The linear guide has zero clearance, arc cutting, bevel cutting, and the surface texture is relatively uniform. It is suitable for high-speed operation and greatly reduces the driving horsepower required for the machine Linear guide rails use rolling instead of sliding, with small friction loss, sensitive response and high positioning accuracy. It can bear the load inthe up, down, left and right directions at the same time. Under the load, the contact surface of the track is still in multi-point contact, and the cutting rigidity will not be reduced; Easy and interchangeable assembly and simple lubricating structure; the linear guides have very little wear and long lasting.

THK Ball Screw

Using high-precision ball screw, with nut preloading and screw

pretensioning treatment, the backlash and temperature rise and

elongation are eliminated in advance, showing excellent positioning

and repeatability.

Direct drive with servo motor to reduce backlash error.

High Precision Motorised Arm for Lathe

Pull-down tool setter with high precision repeatability Available in a variety of different sizes to meet various industrial needs Available in a variety of standard sizes, as well as custom-made steel measuring arms with low coefficient of expansion

Use a robust zirconia probe

Takes up little machine space when not in use

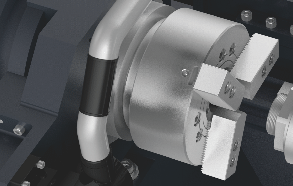

Hydraulic Chuck Workholding

The lathe is equipped with hydraulic through-hole chuck as standard. The chuck can be customized according to customer needs, and a variety of options will give you the most suitable clamping chuck.

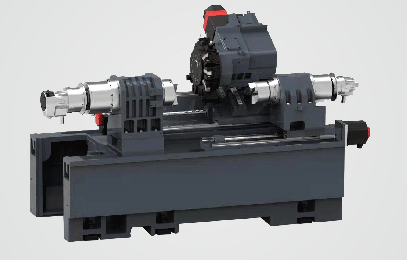

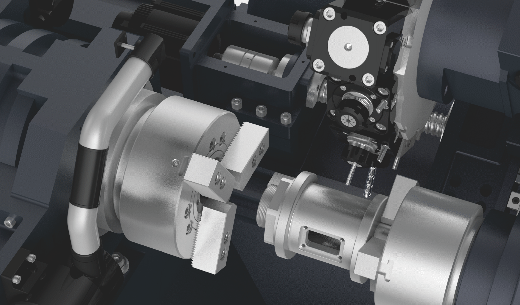

Secondary Spindle

Both ends of the workpiece can be machined at the same time in one clamping, which greatly simplifies the manual operation.