CNC Machine for Valve - Leading Manufacturer in China Solutions

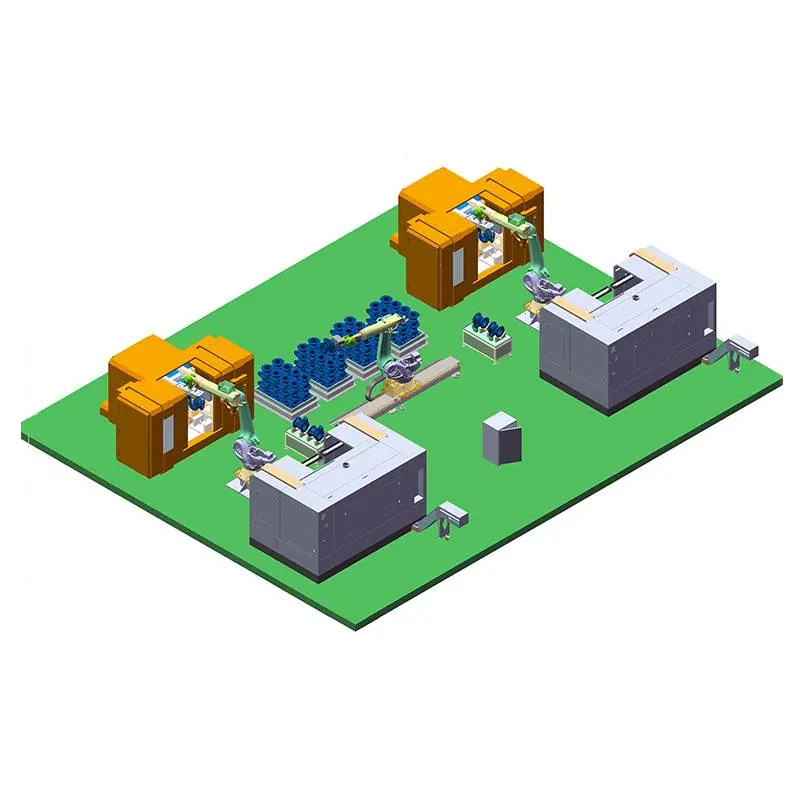

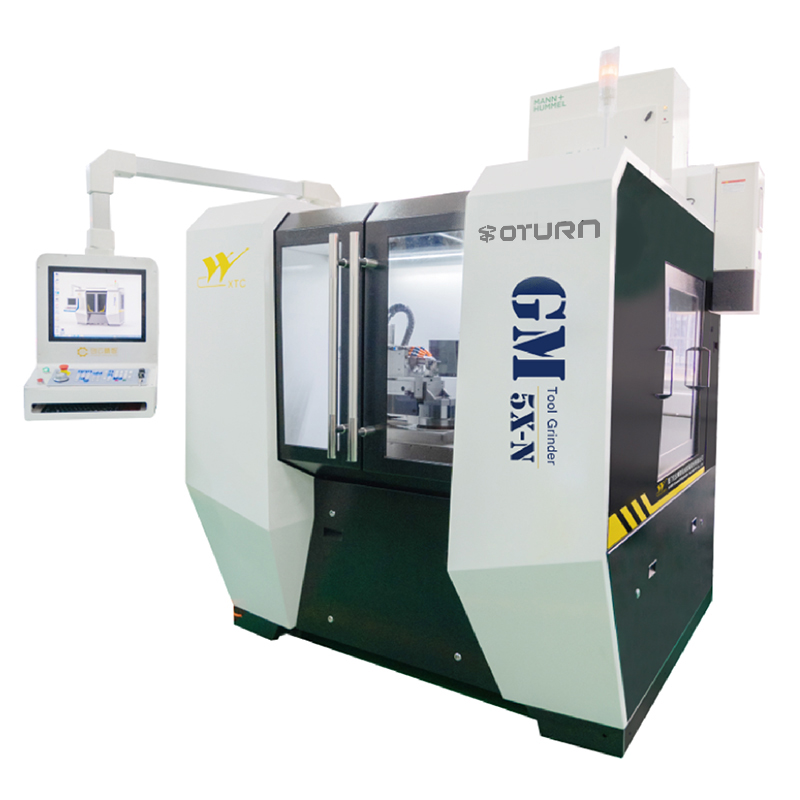

When I think about the best solutions for precision in valve manufacturing, I can't help but emphasize the importance of a reliable CNC machine. Our CNC machine for valve production is specifically tailored to meet the rigorous demands of the industry. Sourced directly from trusted manufacturers in China, I can assure you of its high quality and advanced technology. With features designed for efficiency and accuracy, this machine streamlines your production processes, saving you time and reducing waste. Whether you are a large manufacturer or a small workshop, this machine caters to a range of valve designs and sizes. Its user-friendly interface makes it suitable for both seasoned operators and newcomers alike. Investing in our CNC machine will not only elevate your manufacturing capabilities but also boost your overall business productivity. Let’s take your valve production to the next level together!

Cnc Machine For Valve Winning in 2025 Custom Solutions,

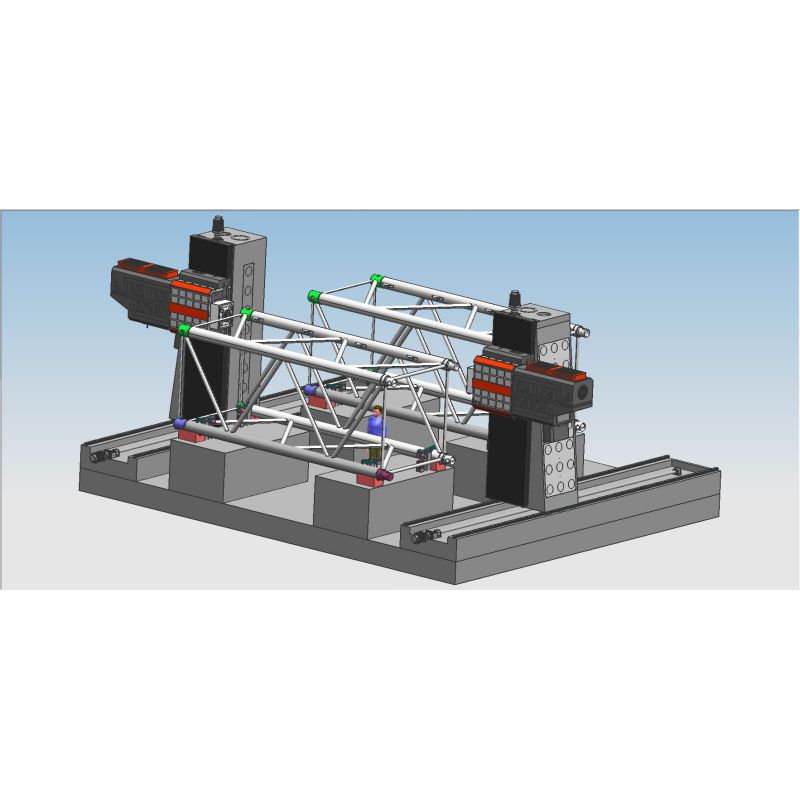

In the fast-evolving landscape of industrial manufacturing, the demand for precision and efficiency is at an all-time high. As we approach 2025, the significance of CNC machines specifically designed for valve production cannot be overstated. These machines offer custom solutions that cater to the intricate requirements of valve manufacturing, ensuring that businesses can achieve both optimal performance and reliability. The advanced capabilities of CNC technology allow for the creation of complex geometries and tight tolerances that are essential in valve applications. Moreover, as industries move towards automation and smart manufacturing, investing in high-quality CNC machines will enable manufacturers to increase productivity while reducing waste and operational costs. Custom solutions provide flexibility, allowing manufacturers to tailor their equipment to meet unique specifications and adapt quickly to changing market demands. In a global marketplace where competition is fierce, leveraging cutting-edge CNC machinery for valve production will not only enhance product quality but also provide a significant competitive edge. As we look towards the future, prioritizing innovation and customization in manufacturing processes will be key to success in the valve industry.

CNC Machine For Valve Winning in 2025 Custom Solutions

| Feature | Specification | Application | Material Compatibility |

|---|---|---|---|

| Spindle Speed | 12000 RPM | Valve machining, drilling | Stainless Steel, Aluminum |

| Axis Configuration | 5-axis | Complex geometries | Titanium, Brass |

| Accuracy | ±0.005 mm | Precision parts production | Carbon Steel, Plastic |

| Tool Changing | Automatic | Efficient operation | All common machining materials |

| Control System | CNC Control Software | User-friendly, programmable | Compatible with various tooling |

Related Products