E30 CNC Cylindrical Grinding Machine For Cutter Tools

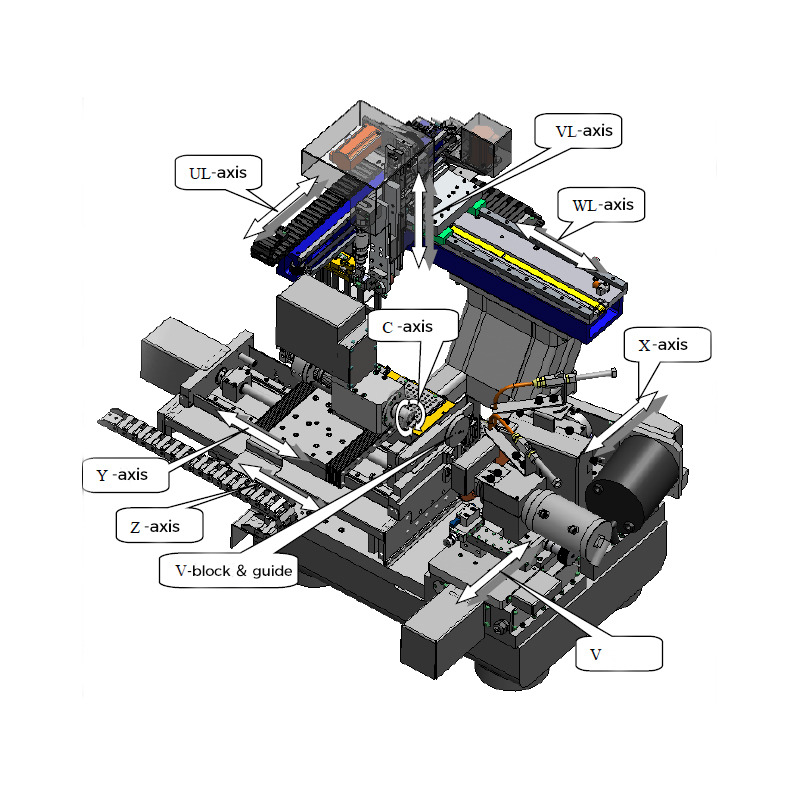

Main structure diagram of machine

Application scope

Application range: milling cutter, drill bit, reamer and various high-precision parts processing.

Processing range: diameter range of processed products: Φ3~Φ20mm, length range of processed products: 120mm (automatic), 330mm (manual).

Processing characteristics: simultaneous grinding of fine and coarse double grinding wheels, one-time processing and forming.

Machine introduction

1. Bed structure:

2. Sheet metal of the whole machine: the whole machine has a fully enclosed structure, and the main frame is separated from the outer cover to avoid vibration

3. Control system: NEWCON

4. The principle of trimming:

• X-axis (coarse grinding wheel mechanism): realize the reciprocating motion of the coarse grinding wheel in the X-axis direction;

• V-axis (fine grinding wheel mechanism): realize the reciprocating motion of the fine grinding wheel in the V-axis direction;

• Y-axis (Y-axis feed mechanism): realize the reciprocating movement of the worktable in the Y-axis direction;

• C axis (working head rotation mechanism): realize the rotary motion of the working head in the direction of the C axis:;

• UL axis, VL axis and WL axis (manipulator pick-and-place mechanism): realize the reciprocating motion of the manipulator in the horizontal and vertical directions;

• Guide wheel and V-block support: Auxiliary to the completion of machining.

1. Moving parts: X axis, V axis, Y axis, WL axis, UL axis, VL axis, guide wheel mechanism, arm mechanism, hysteresis adjustment mechanism

2. Workpiece spindle: Chuangyun self-made spindle

3. Grinding spindle: Xiamen Tungsten Motor

4. Lubrication of the whole machine: oil nipples are reserved for each axis and lubricated regularly

5. Feeding method: three-axis manipulator feeding

Technical specifications

|

control method |

External buttons, touch screen |

|

|

Display method |

Touch screen, warning light |

|

|

cooling method |

Oil cooler |

|

|

transfer method |

Hydraulic, pneumatic, servo motor |

|

|

power supply |

AC 3×380V ,50Hz |

|

|

Maximum total power |

25KW |

|

|

Dimensions |

2152×1838×2614 mm |

|

|

gross weight |

3050kg |

|

|

Cooling oil pressure |

0.6~0.8MPa |

|

|

barometric pressure |

Total road pressure: 5~6Bar |

|

|

Chuck air pressure: 2~3Bar |

||

|

Guide wheel air pressure: 2~2.5Bar |

||

|

Gripper air path pressure: 1.5~4Bar |

||

|

Arm air pressure: 5~6Bar |

||

|

Optical scale cleaning air pressure: 0.6~0.7Bar |

||

|

Manipulator parameters |

||

|

UL axis |

Travel |

450mm |

|

Repeatability |

0.02mm |

|

|

Maximum operating speed |

15000mm/min |

|

|

VL axis |

Travel |

100mm |

|

Repeatability |

0.02mm |

|

|

Maximum operating speed |

15000mm/min |

|

|

WL axis |

Travel |

540mm |

|

Repeatability |

0.02mm |

|

|

Maximum operating speed |

15000mm/min |

|

|

Processing axis parameter |

||

|

Y axis |

Travel |

350mm |

|

Minimum Resolution Accuracy |

0.0001mm |

|

|

X axis |

Travel |

35mm |

|

Minimum Resolution Accuracy |

0.0001mm |

|

|

V axis |

Travel |

35mm |

|

Minimum Resolution Accuracy |

0.0001mm |

|

|

Guide wheel |

Rotation accuracy: |

≤0.010mm |

|

Working head (C axis) |

Motor Power |

1.57Kw |

|

Rotating speed |

≤2000rpm |

|

|

Runout accuracy |

≤0.002mm |

|

|

minimum resolution |

0.0001° |

|

|

Rough grinding wheel spindle |

Motor Power |

8.5KW |

|

Rotating speed |

≤5000rpm |

|

|

Runout accuracy |

≤0.002mm |

|

|

dynamic balance |

≤G0.4 |

|

|

Fine grinding wheel spindle |

Motor Power |

1.4KW |

|

Rotating speed |

≤7950rpm |

|

|

Runout accuracy |

≤0.002mm |

|

|

dynamic balance |

≤G0.4 |

|

|

Grinding parameters |

|

|

|

Chuck model |

W20 |

|

|

Coarse grinding wheel diameter |

Ø250mm |

|

|

Fine grinding wheel diameter |

Ø150mm |

|

|

Workpiece Shank Diameter |

Ø3-Ø12mm (automatic) / Ø3-Ø20mm (manual) |

|

|

Workpiece Grinding Range |

Ø0.08 - Ø20mm |

|

|

workpiece length |

120mm(automatic) / 350mm(manual) |

|

|

The maximum processing length of the workpiece |

330mm |

|

|

Processing outer diameter runout |

≤0.003mm |

|

|

Length machining accuracy |

±0.1mm |

|

|

Angle machining accuracy |

≤0.3° |

|

|

Appearance accuracy |

≤Ra0.4 (finish grinding) |

|

Standard configuration list

|

10 |

CNC system |

NEWC0N |

1 |

|

20 |

servo motor |

NEWC0N |

8 |

|

30 |

server Driver |

NEWC0N |

4 |

|

40 |

Operation panel/hand wheel |

NEWC0N |

1 |

|

50 |

High precision working head module |

GESAC |

1 |

|

60 |

High-precision electric spindle (1.4KW) |

GESAC |

1 |

|

70 |

High precision motor (7.1KW) |

GESAC |

1 |

|

80 |

High Precision Mechanical Spindle |

GESAC |

1 |

|

90 |

Precision rail |

Schneeberger |

10 |

|

100 |

Precision Crossed Roller Linear Way |

Schneeberger |

4 |

|

110 |

Precision Ball Screw |

NSK |

4 |

|

120 |

Operation and processing simulation software (standard step difference, spherical, etc.) |

GESAC |

1 |

|

130 |

Inverter |

GESAC |

1 |

|

140 |

Inverter |

GESAC |

1 |

|

150 |

touch screen |

19寸ELO |

1 |

|

160 |

Machine tool safety door lock device |

Jinzhong |

1 |

|

170 |

sensor |

Baumer |

3 |

|

180 |

flow sensor |

Yifumen |

1 |

|

190 |

Electrical components |

Schneider |

1 |

|

200 |

Pneumatic Components |

CKD |

1 |

|

210 |

Wire and Cable |

ComCab |

1 |

|

220 |

Rack air conditioner |

GESAC |

1 |

|

230 |

Precision pressure wheel Ø92x8 |

GESAC |

1 |

|

240 |

Precision pressure wheel Ø92x15 |

GESAC |

1 |

|

250 |

Chuck W20 D4 |

GESAC |

1 |

|

260 |

Standard tray D4 |

GESAC |

3 |

|

260 |

High-precision matching V-block (3-6)*10 |

GESAC |

1 |

|

280 |

High precision grinding wheel flange (quick change type) |

GESAC |

2 |

|

290 |

Full set of manipulator fingers |

GESAC |

1 |

Machine characteristics

7 CNC axes, 4 CNC axes are used in the processing area, which can realize automatic loading and unloading, batch unmanned production

Machining accuracy and efficiency of machine tools

1. The radial runout of the workpiece is within 0.003mm;

2. The accuracy of size 2.0 is controlled within ±0.005mm;

3. The roundness of the workpiece is within 0.003mm;

4. Surface roughness < Ra0.4;