CNC Drum Drilling Machine - Leading Manufacturer in China

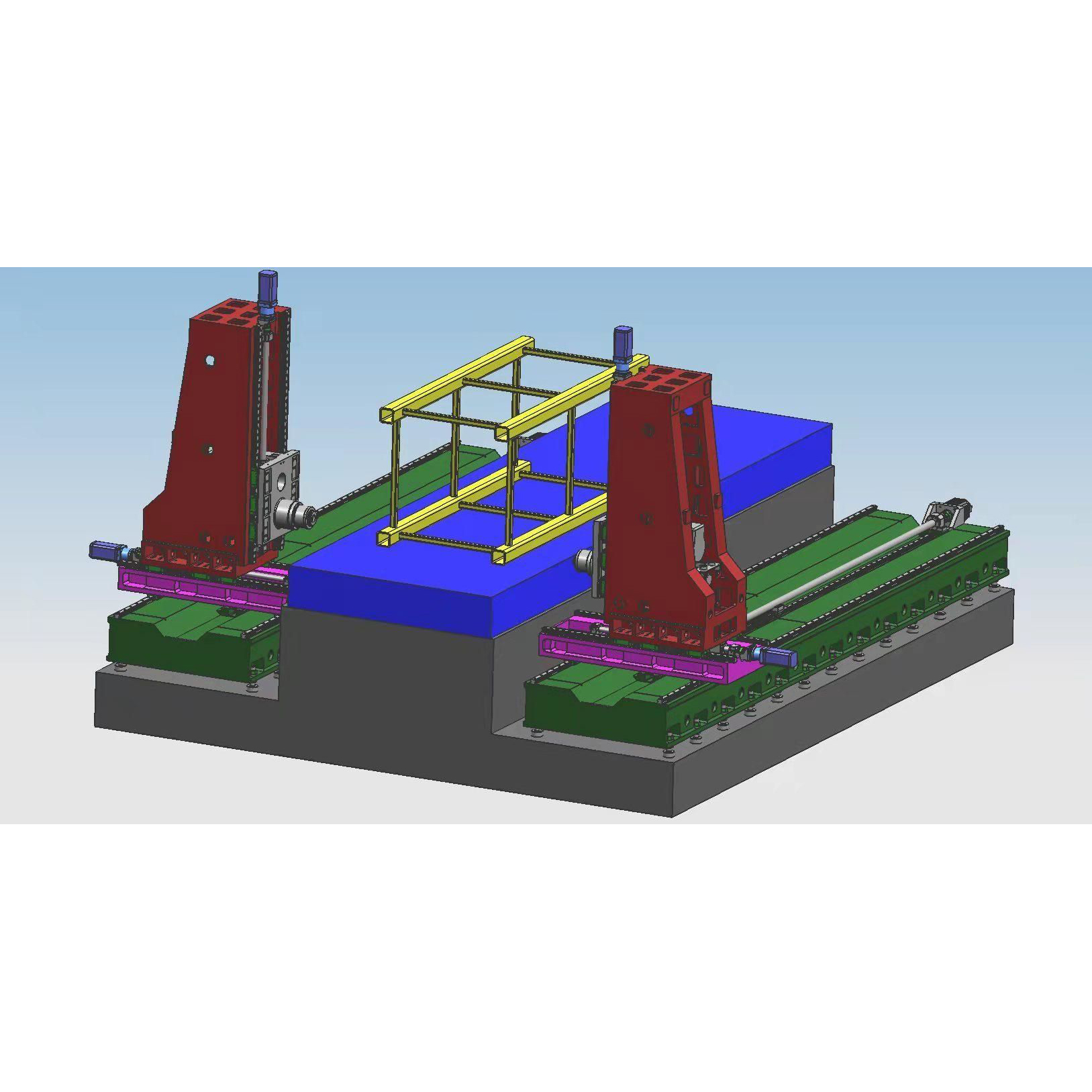

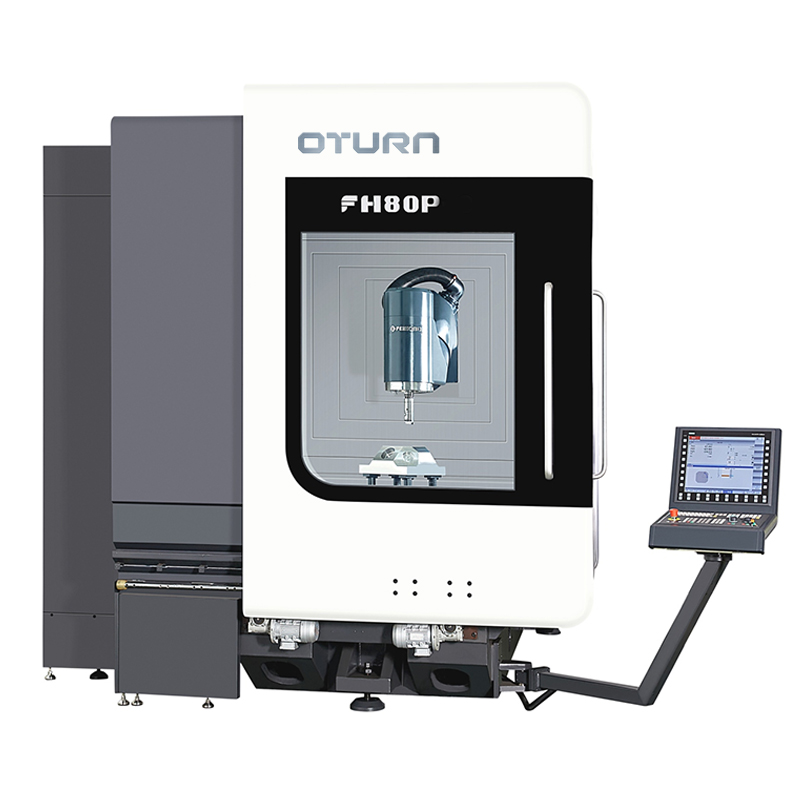

Our Cnc Drum Drilling Machine is designed with precision and reliability in mind, making it the perfect choice for your manufacturing needs. As a leading manufacturer in China, we pride ourselves on delivering high-quality machinery that enhances productivity and efficiency. This machine is equipped with advanced CNC technology, ensuring accurate drilling and optimal performance for various applications. With a user-friendly interface, I find it easy to operate, even for complex projects. Its robust construction guarantees durability, reducing downtime and maintenance costs. Plus, the energy-efficient design means you can save on operational expenses while still achieving outstanding results. I understand that in the fast-paced world of manufacturing, every second counts. That's why our Cnc Drum Drilling Machine is built to help you stay ahead of the competition. By investing in this machine, you'll not only enhance your production capabilities but also boost your bottom line. Choose us and experience the difference in quality and service from a trustworthy manufacturer in China.

Cnc Drum Drilling Machine Dominates Pioneers in the Field

In the ever-evolving landscape of manufacturing, CNC drum drilling machines stand out for their precision and efficiency, making them a crucial asset for businesses looking to enhance productivity. With advanced technology that automates the drilling process, these machines ensure consistent quality and reduce operational costs, giving pioneering companies a competitive edge. Their versatility in handling various materials and designs allows manufacturers to adapt quickly to changing market demands. Moreover, embracing CNC drum drilling technology can significantly accelerate production timelines. These machines not only minimize human error but also enable intricate and complex drilling patterns that manual methods cannot achieve. This leads to increased throughput and the ability to take on more diverse projects, ultimately driving growth and innovation within the manufacturing sector. As global industries continue to seek advanced solutions to meet their production needs, the dominance of CNC drum drilling machines is set to expand. Companies that invest in this technology will not only enhance their operational efficiency but also position themselves as leaders in their respective fields, ready to tackle the challenges of tomorrow's manufacturing landscape.

CNC Drum Drilling Machine Dominates Pioneers in the Field

| Dimension | Specification | Application | Technology Used | Advantages |

|---|---|---|---|---|

| Drilling Depth | Up to 100 mm | Metal and Plastic Components | CNC Control System | High Precision |

| Feed Rate | 0.1 to 2 m/min | Automotive Industry | Hydraulic Actuators | Efficient Material Removal |

| Spindle Speed | 500 to 3000 RPM | Aerospace Components | Servo Motors | Versatile Operations |

| Weight Capacity | Up to 500 kg | Heavy Duty Parts | Computer-Aided Design | Enhanced Durability |

| Control Software | Proprietary Software | General Manufacturing | Real-Time Monitoring | User-Friendly Interface |

Related Products