Top 5 Axes CNC Machine Manufacturers in China for Precision Engineering

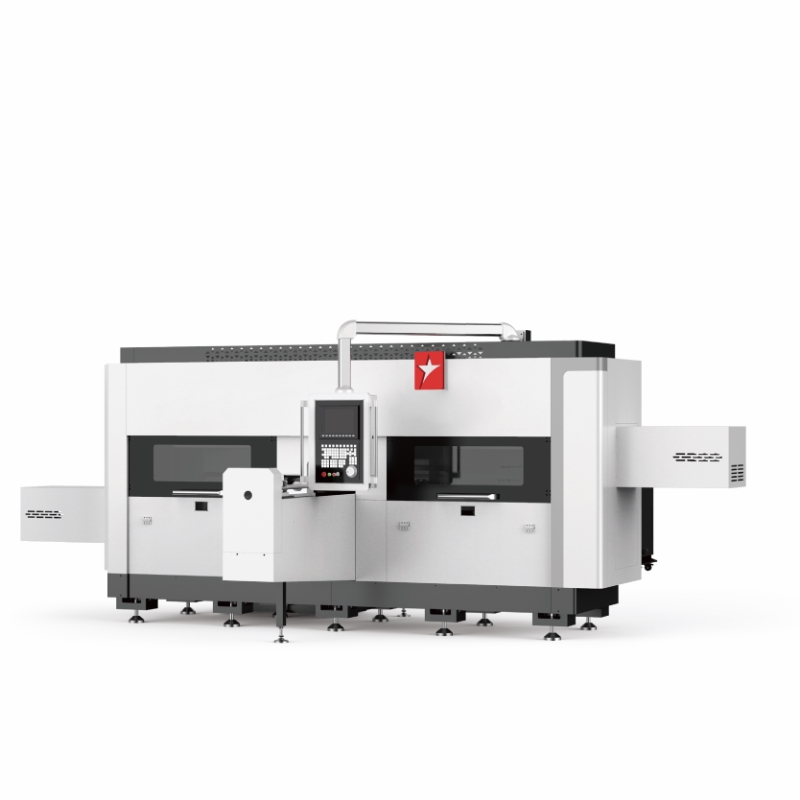

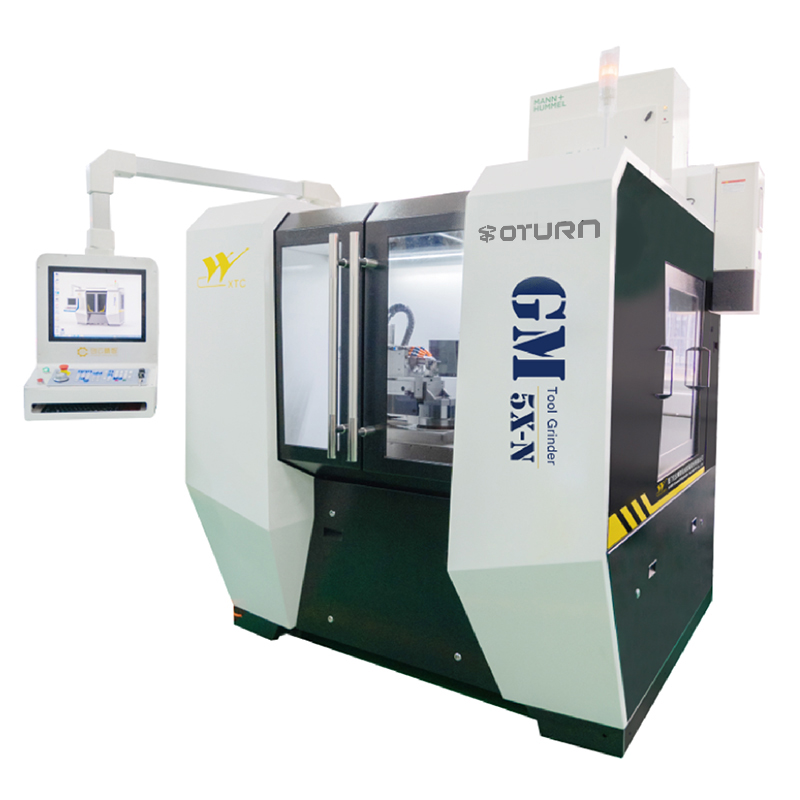

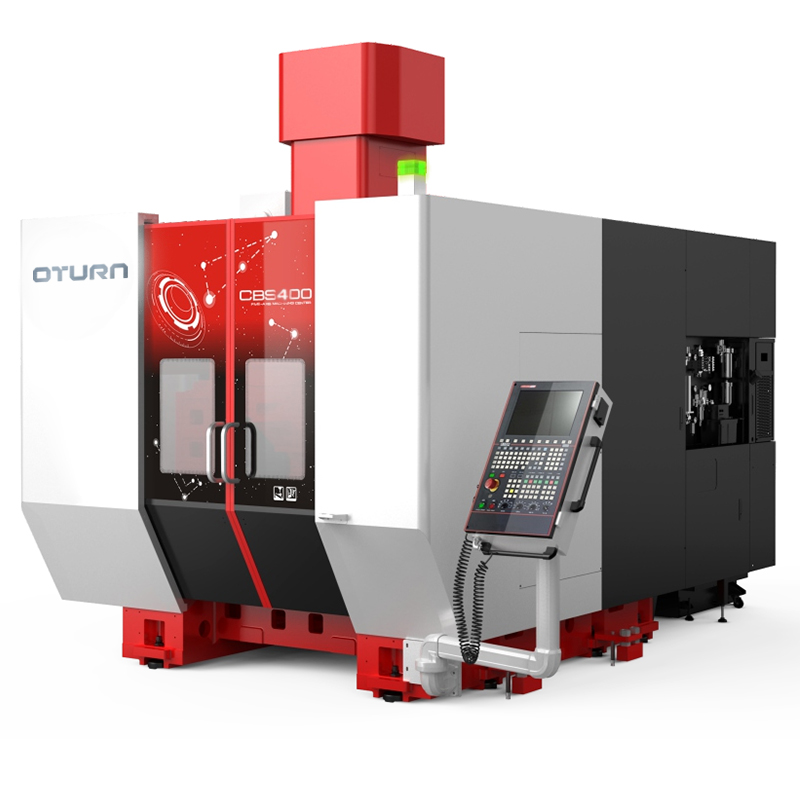

Are you searching for a reliable solution to enhance your machining capabilities? Our 5 Axes CNC Machine, crafted in China, is the perfect choice for businesses looking to boost their production efficiency. With precision engineering and reliable performance, this machine allows you to tackle complex designs with ease, ensuring high-quality results every time. I understand the importance of finding a dependable manufacturer, and that’s why I’m proud to offer our state-of-the-art technology. The 5 Axes CNC Machine is designed to deliver exceptional accuracy and speed, ideal for various industries, from aerospace to automotive. Plus, our commitment to quality ensures that you receive a product that meets your highest standards. Investing in our 5 Axes CNC Machine means you can streamline your operations and stay ahead of the competition. Let’s take your manufacturing processes to the next level together!

5 Axes CNC Machine Stands Out Dominates

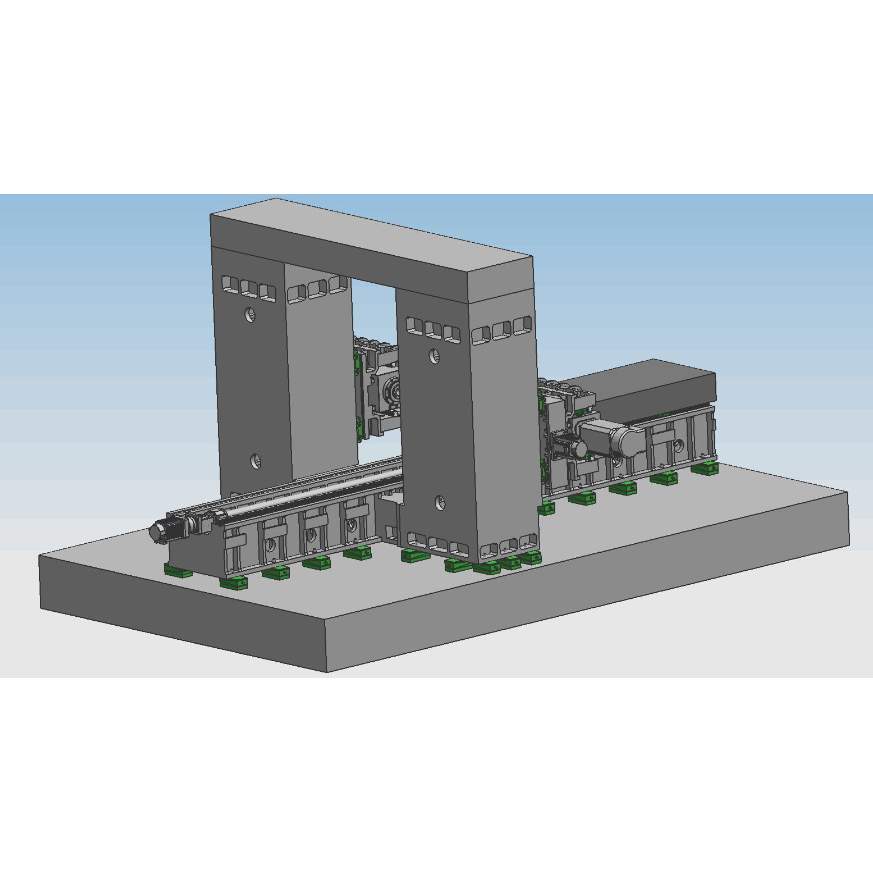

The 5 Axes CNC Machine is transforming the manufacturing landscape with its unparalleled precision and efficiency, making it a vital asset for businesses aiming to enhance their productivity. By allowing for simultaneous movement along multiple axes, this advanced machine significantly reduces setup time and offers the ability to create complex geometries with high precision. This capability not only streamlines the production process but also opens the door to innovative designs that were previously challenging to achieve with traditional machining methods. For global buyers, investing in a 5 Axes CNC Machine means aligning with the future of manufacturing. It enables companies to respond swiftly to market demands and customize products with ease. The versatility of this machine extends across various industries, including aerospace, automotive, and medical devices, where precision and quality are paramount. Furthermore, its user-friendly interface and enhanced software integration facilitate a seamless transition into more automated production lines, thereby boosting overall efficiency and reducing operational costs. As the demand for high-quality machined components continues to rise, the 5 Axes CNC Machine stands out not just as a tool, but as a strategic partner in driving operational excellence. Its ability to deliver consistent results while minimizing waste and maximizing uptime positions businesses for sustained growth in an increasingly competitive marketplace. Embracing this technology is not merely an upgrade; it is an essential step toward achieving manufacturing superiority.

5 Axes CNC Machine Stands Out Dominates

| Feature | Specification | Advantage |

|---|---|---|

| Axis Number | 5 | Enhanced flexibility for complex designs |

| Max Speed | 30,000 RPM | Faster production cycles |

| Work Envelope | 800 x 800 x 500 mm | Suitable for large parts manufacturing |

| Control System | CNC Controller | Easy programming and operation |

| Material Compatibility | Metals, Plastics, Composites | Versatile for various industries |

| Software Compatibility | CAD/CAM Software | Streamlined design to production workflow |

Related Products