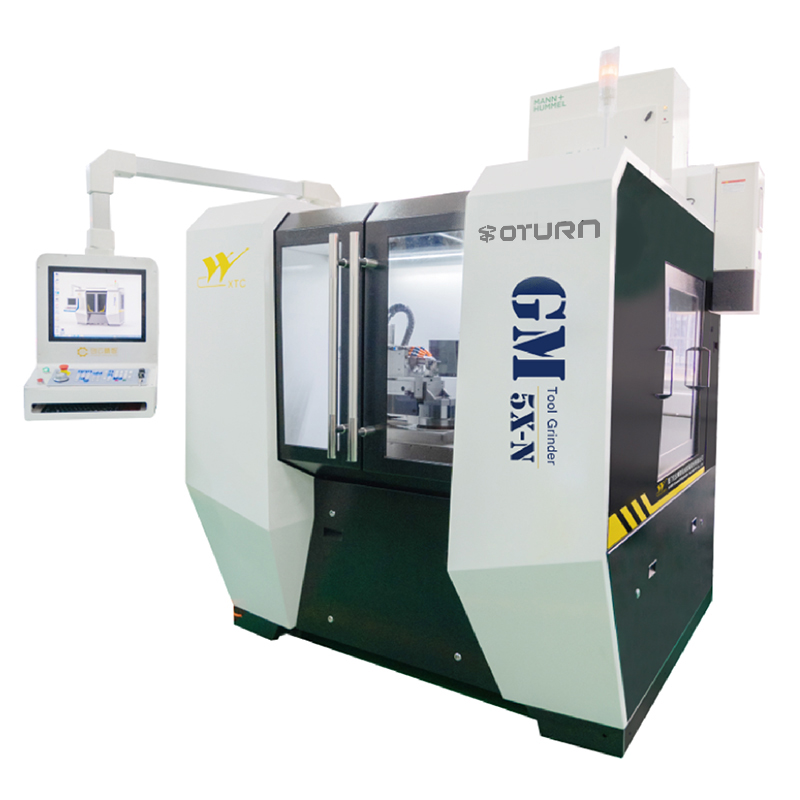

Top China Manufacturer of Vertical CNC Machines for Precision Engineering

As a professional in the CNC machinery industry, I understand the importance of reliability and precision in manufacturing. Our vertical CNC machine is designed to meet the high demands of today’s production environments, especially for those sourcing equipment from China. With a focus on quality, our machines are crafted by skilled manufacturers who prioritize efficiency and durability. This vertical CNC machine not only enhances machining accuracy but also boosts productivity, making it an ideal choice for companies looking to streamline their operations. Whether you're a small business or a large manufacturer, investing in our vertical CNC machine means investing in your future. I invite you to explore the incredible potential it brings to your manufacturing process. Choosing us means having a partner dedicated to your success, ensuring you stay competitive in the evolving marketplace. Let's take your business to new heights together!

Vertical Cnc Machine Application in 2025

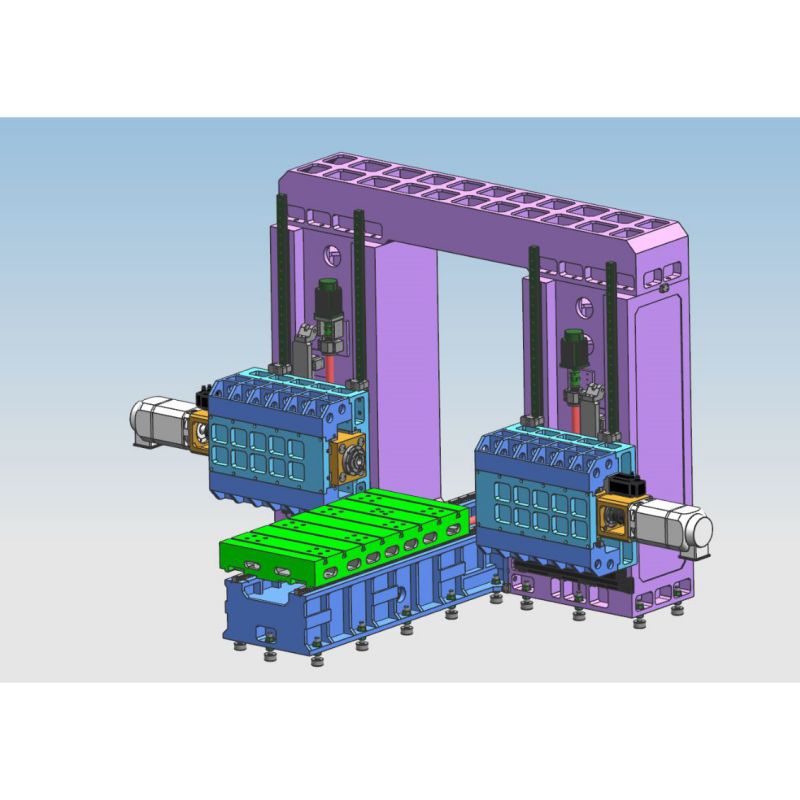

As we approach 2025, the application of vertical CNC machines is poised to revolutionize various industries worldwide. These advanced machining tools offer unparalleled precision and efficiency, making them essential for sectors such as aerospace, automotive, and medical manufacturing. The growing demand for high-quality components, coupled with the rise of automation and smart manufacturing, underscores the importance of integrating vertical CNC technology into production processes. Vertical CNC machines are particularly advantageous for producing complex geometries and intricate designs. Their vertical configuration provides enhanced visibility and accessibility, allowing for more straightforward setup and maintenance. This capability is crucial for global procurement buyers looking for solutions that not only meet tight production schedules but also deliver superior quality. With the added benefit of reduced operational costs through increased speed and efficiency, investing in vertical CNC machinery is becoming a strategic decision for manufacturers aiming to stay competitive in the international market. Moreover, as industries strive for sustainability, vertical CNC machines support greener manufacturing practices. These machines minimize waste through precise material removal and enable the use of sustainable materials, aligning with global efforts to reduce the environmental impact of production. In conclusion, the application of vertical CNC machines in 2025 will not only enhance production capabilities but also drive innovation and sustainability, making them a smart choice for procurement professionals looking to future-proof their operations.

Vertical CNC Machine Application in 2025

| Application Area | Key Benefits | Material Used | Industry | Technological Features |

|---|---|---|---|---|

| Aerospace Component Manufacturing | High precision and reduced waste | Aluminum alloys, titanium | Aerospace | 5-axis machining, high-speed spindles |

| Automotive Prototype Production | Rapid prototyping and iteration | Steel, plastic composites | Automotive | Adaptive controls, CAD integration |

| Medical Device Fabrication | Enhanced safety and hygiene | Stainless steel, titanium alloys | Medical | Automation, CNC precision |

| Electronics Enclosures Production | Increased design flexibility | Plastics, aluminum | Electronics | Flexible tooling, digital design |

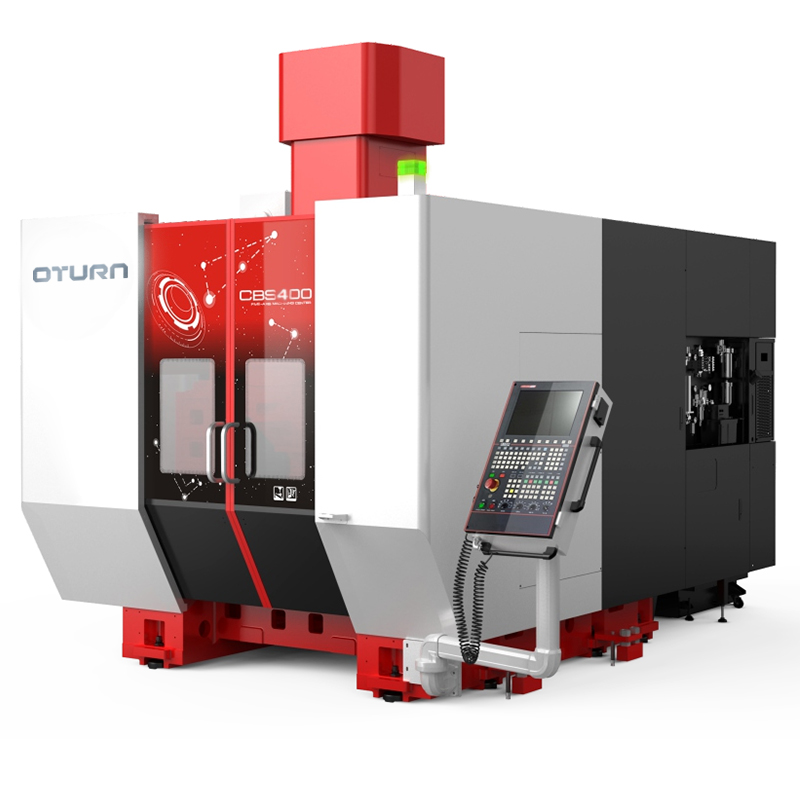

Related Products