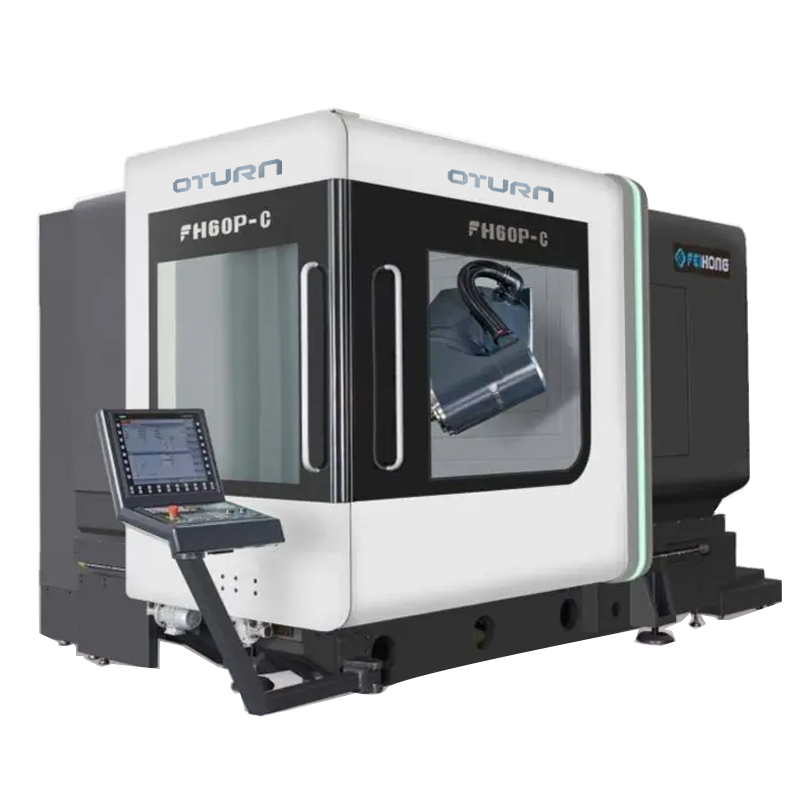

Top Valve Repair Machines from Leading China Manufacturer - Quality Guaranteed

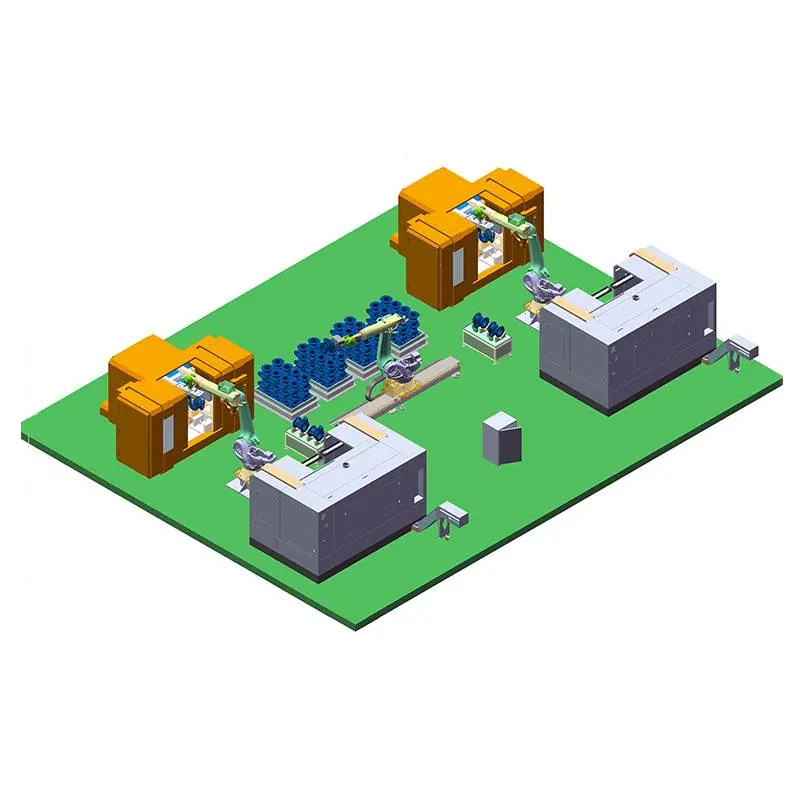

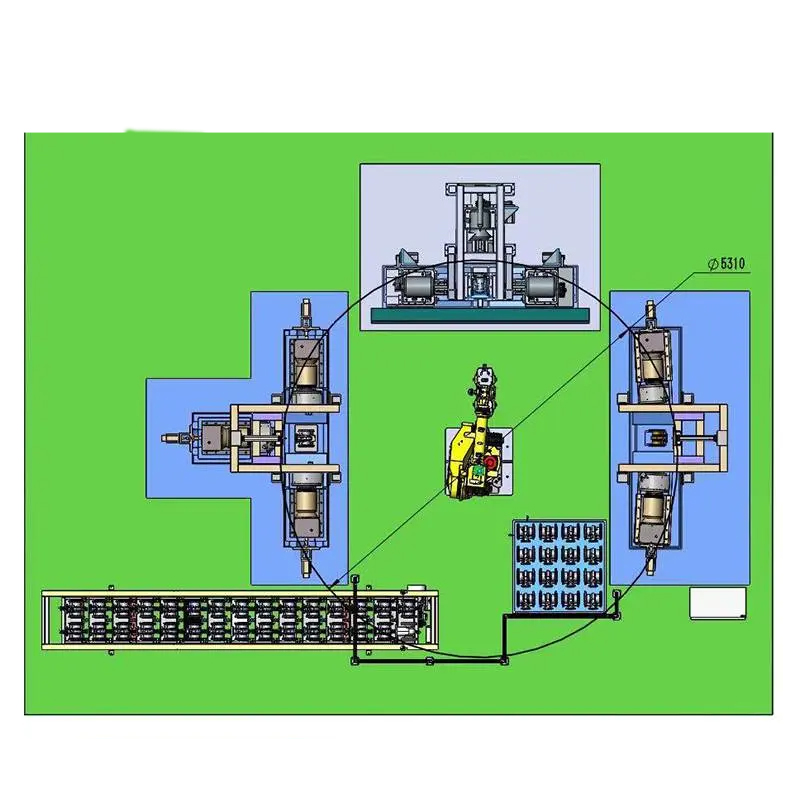

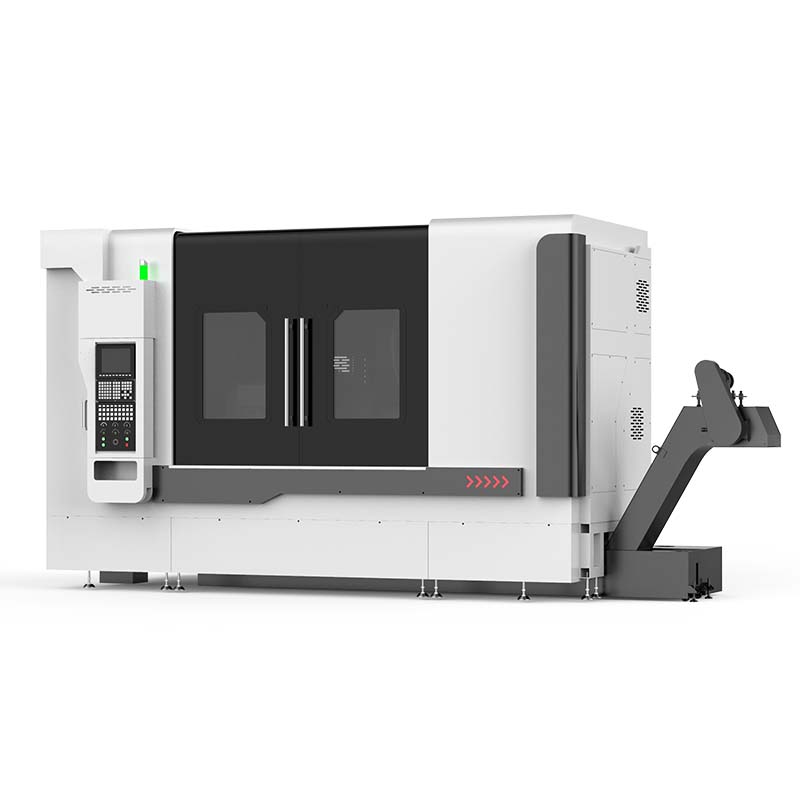

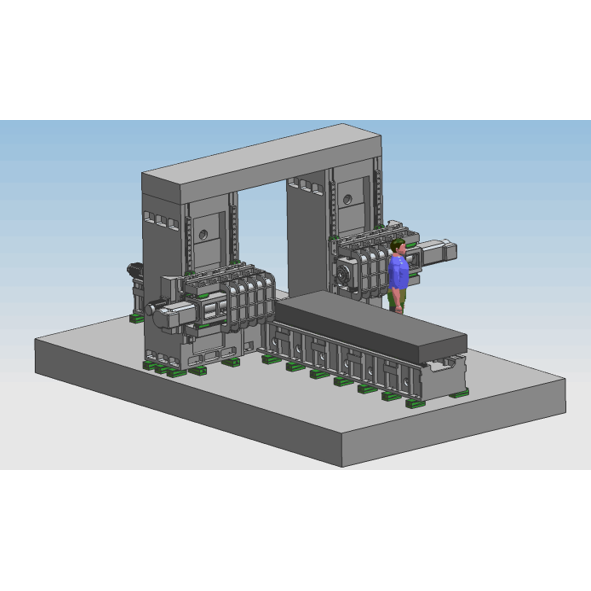

As a leading provider of valve repair machines, I know how crucial it is to have reliable equipment in your operations. Our machines, manufactured in China, are designed to streamline your repair process and enhance efficiency. With cutting-edge technology and robust construction, they ensure precision and durability, significantly reducing downtime in your facility. I've witnessed firsthand how our valve repair machines can transform workflows, allowing businesses to tackle even the most challenging tasks with ease. Whether you're in the oil and gas industry or manufacturing plants, our machines cater to a wide range of applications, making them an essential investment for any serious operation. Plus, as a reputable manufacturer, we stand by our commitment to quality and customer satisfaction. Let’s elevate your valve repair capabilities together with our top-of-the-line solutions that meet your business needs.

Valve Repair Machines Manufacturer Service Backed by Expertise

In today's competitive manufacturing sector, having the right equipment is crucial for ensuring efficiency and quality. Valve repair machines are indispensable tools that enable companies to maintain and restore the functionality of valves, which are vital components in various industries, including oil and gas, water treatment, and power generation. When it comes to sourcing these machines, it’s essential to partner with a manufacturer that not only provides top-tier technology but also offers unparalleled service and support. Choosing a valve repair machine manufacturer with deep expertise in the field can make a significant difference. Such manufacturers understand the complexities involved in valve maintenance and can provide machinery and solutions tailored to specific needs. Their focus on innovation means they continuously improve their products to meet the evolving standards of different industries, ensuring that buyers invest in durable and efficient machinery that enhances productivity and minimizes downtime. Additionally, robust after-sales support is a critical factor for global buyers. A reliable manufacturer should offer comprehensive training, maintenance services, and readily available spare parts. This commitment ensures that your operations run smoothly, and any potential issues are addressed promptly, allowing your business to thrive in a demanding market. By investing in high-quality valve repair machines and the expertise that accompanies them, organizations can achieve long-term operational success and maintain a competitive edge.

Valve Repair Machines Manufacturer Service Backed by Expertise

| Machine Type | Features | Applications | Customer Support |

|---|---|---|---|

| Automatic Valve Tester | Precision testing, Automatic calibration | Oil and Gas, Water Treatment | 24/7 Technical Support |

| Hydraulic Valve Repair Station | Hydraulic testing, Pressure performance | Manufacturing, Aerospace | Dedicated Account Manager |

| Pneumatic Valve Testing Equipment | Leak detection, Pressure testing | Pharmaceutical, Food Industry | On-site Training Available |

| Smart Valve Diagnostics | IoT Integration, Real-time monitoring | Energy Sector, Water Management | Remote Troubleshooting |

| Custom Valve Repair Solutions | Tailored service, Quick turnaround | Various Industries | Consultation Services |

Related Products