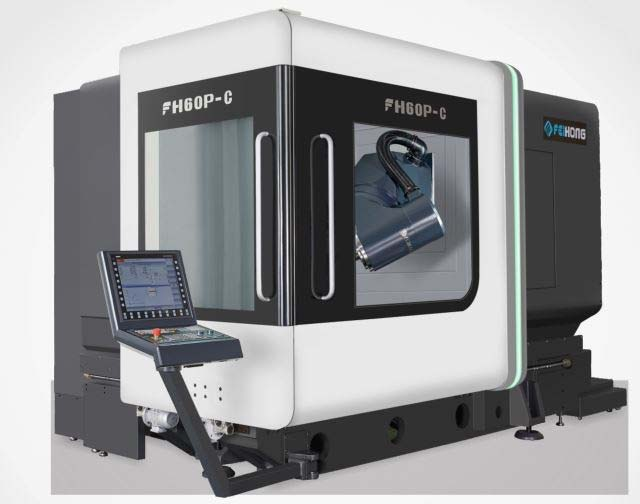

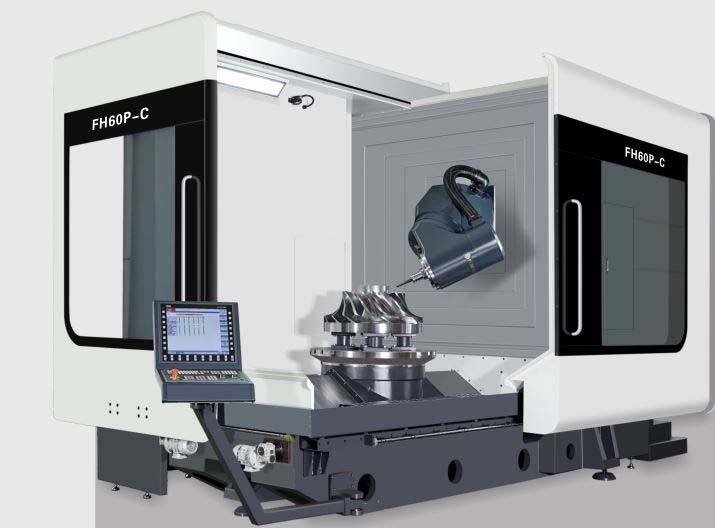

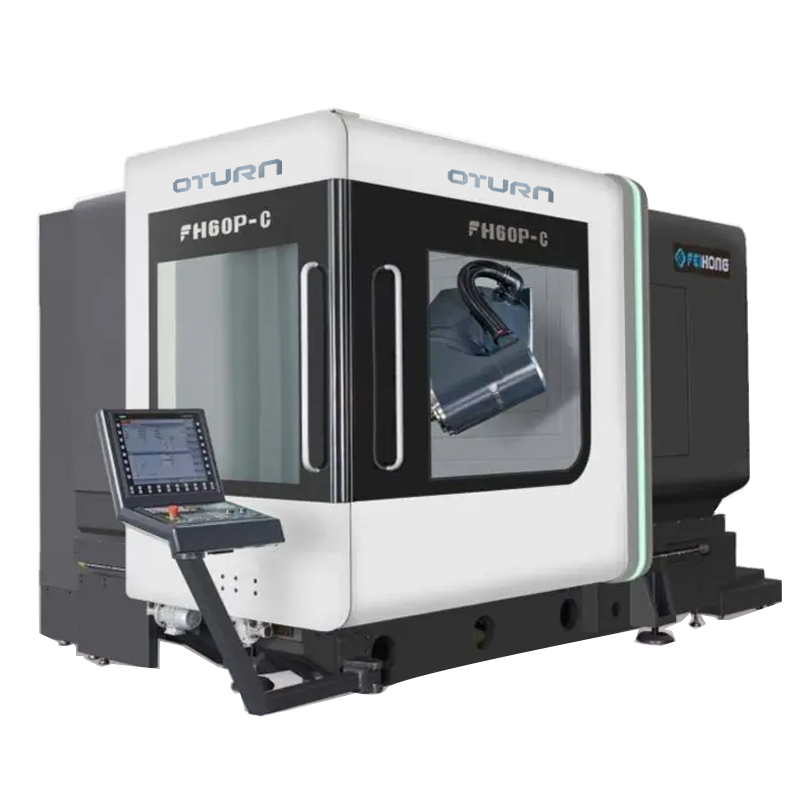

5-axis Simultaneous Milling Turning 60P-C

Scope of supply

Standard accessories function table (please refer to the controller function for the electric control part)

1. Siemens 840DSL controller

2. Brand Own five-axis multi-function swing head

3. Electric spindle DGZX-24012/34B2-KFHWVJS

4. HSK-A63 40 tool magazine automatic tool changing system

5.X/Y/Z hollow cooling ball screw drive

6. Roller linear slides (2 each for X/Y/Z axis)—BOSCH REXROTH

7. X/Y/Z three-axis fully closed-loop optical ruler

8. Electrical box temperature control device

9. Spindle cooler

10. Spiral chip rolling device and rear iron chip conveyor iron chip car

11. Water from the center of the spindle, annular water spray

12. Blow air in the center of the spindle, and blow air in the ring.

13. The five-axis head crescent moon blows water, and the crescent moon blows air.

14. 1 type of safety interlock for front and side working doors

15. Spindle circulation cooling device.

16. Waterproof working fluorescent lamp

17. Hydraulic station device

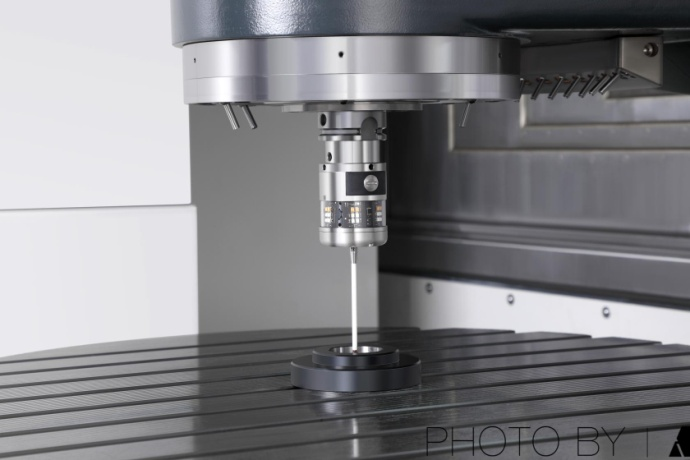

18. Renishaw OMP60 Infrared Probe Unit

19. Renishaw Laser Tool Setter

20. Central centralized automatic feeding lubrication device

21. Operation side cleaning water gun and air interface

22. Cutting fluid cooling system

23. Fully enclosed protective sheet metal

24. Operation box

25. The electrical box is equipped with an air conditioner

26. Siemens electronic handwheel

27. Foot-operated spindle tool release switch

28. Foundation level pads and foundation bolts

29. Adjustment tools and toolboxes

30. Technical Manual

Parameter

|

Model |

Unit |

FH60P-C |

|

Travel |

||

|

X axis travel |

mm |

600 |

|

Y axis travel |

mm |

800 |

|

Z axis travel |

mm |

600 |

|

Distance from spindle nose to work table surface |

mm |

150-750 |

|

Horizontal milling head |

mm |

30-630 |

|

Feed/fast moving speed |

m/min |

40 |

|

Feed force |

KN |

10 |

|

Rotary table (C axis) |

||

|

Working table size |

mm |

Ø630 |

|

Max.table load (mill) |

kg |

2000 |

|

Max.table load (turning) |

kg |

1000 |

|

Rotray table |

rpm |

60 |

|

Milling/turning woking table (compound milling and turning) |

rpm |

600 |

|

Minimum split angle |

° |

0.001 |

|

Model |

Unit |

FH80P-C |

|

Rated torque |

Nm |

807 |

|

maximum torque |

Nm |

1430 |

|

CNC swing milling head (B axis) |

||

|

Swing range(0=Vertical/180=Level) |

° |

-15~180 |

|

Fast moving and feeding speed |

rpm |

80 |

|

Minimum split angle |

° |

0.001 |

|

Rated torque |

Nm |

743 |

|

maximum torque |

Nm |

1320 |

|

Spindle (milling and turning) |

||

|

Spindle speed |

rpm |

12000 |

|

Spindle power |

Kw |

34/42 |

|

Spindle torque |

Nm |

132/185 |

|

Spindle tapre |

|

HSKA63 |

|

Distance from spindle center to beam guideway surface |

mm |

1064.5 |

|

Model |

Unit |

FH60P-C |

|

Tool magazine |

||

|

Tool interface |

|

HSKA63 |

|

Tool magazine capacity |

PCS |

40 |

|

Max.tool diameter/length/weight |

|

Ø85/300/8 |

|

Tool switch(Tool to) |

S |

1.8 |

|

Measuring device |

||

|

Infrared probe |

Rensishaw OMP60 |

|

|

Tool detection instrument in working processing area |

|

Rensishaw NC4F230 |

|

Processing capacity |

|

|

|

Max.drilling diameter(Medium steel) |

|

Ø40 |

|

Max.tapping diameter(Medium steel) |

|

M24 |

|

Max.milling diameter(Medium steel) |

|

250 |

|

Position accuracy (ISO230-2 and VDI3441) |

||

|

X/Y/Z positioning accuracy |

mm |

0.005 |

|

X/Y/Z Repeat positioning accuracy |

mm |

0.004 |

|

B/C positioning accuracy |

|

8" |

|

B/C Repeat positioning accuracy |

|

4" |

|

Model |

Unit |

FH80P-C |

|

CNC controller |

|

|

|

Control system |

|

Siemens840D |

|

Others |

|

|

|

Machine height(General machine) |

mm |

2985 |

|

Occupied area for main machine(L*W) |

mm |

4300x2600 |

|

Occupied area for tool magazine(L*W) |

mm |

2100x1250 |

|

Occupied area for chip conveyor(L*W) |

mm |

3070x1065 |

|

Occupied area for water tank(L*W) |

mm |

1785x1355 |

|

Grand total occupied area to complete machine(L*W) |

mm |

5200x3550 |

|

Machine weight |

Kg |

15000 |

Machine CNC controller

|

Control System |

Siemens 840DSL (motor and drive) |

||

|

Number of control axes |

5-axis simultaneous milling turning (NC axis + spindle, BC axis) |

||

|

Simultaneous control of 5 axes Simultaneous milling with turning |

positioning axis |

Standard X, Y, Z, B, C |

|

|

interpolation |

straight line |

X, Y, Z, B, C axes (X, Y, Z, B, C can be compensated) |

|

|

arc |

X, Y, Z, B, C axes (X, Y, Z, B, C can be compensated) |

||

|

Minimum instruction unit |

0.001um |

||

|

minimum control unit |

0.1nm |

||

|

show |

19LCD |

||

|

motor |

Triple overload capability with absolute encoder (encoder position is never lost) |

||

|

External communication function |

Ethernet and RS232C interface |

||

|

Operation mode |

MDI, Auto, Manual, Handwheel, Origin (absolute), REPOS |

||

|

programmatically |

Online ISO language editor |

||

|

Maximum PLC programming storage capacity |

2048KB |

||

|

Interpolation function |

Straight lines, circles through and through center points, spirals, fine surfaces, high speed settings, etc. |

||

|

Number of tool offsets |

512 groups |

||

|

Handwheel magnification |

0.1/0.01/0.001mm |

||

|

Minimum setting and moving units |

1um/X,Y,Z |

||

|

data saving |

Memory data will never be lost when power off |

||

|

feed rate |

0%-150% |

||

|

Fast forward magnification |

0%-100% |

||

|

Input and output interface |

Ethernet and RS232C interface, CF card, USB storage backup |

||

|

display language |

Chinese and English |

||

Standard configuration quantity

|

No |

Accessory name |

unit |

Qty |

|

1 |

foot control switch |

set |

1 |

|

2 |

Hydraulic clamping mechanism |

set |

1 |

|

3 |

Centralized Lubrication Device |

set |

1 |

|

4 |

cooling system |

set |

1 |

|

5 |

working lamp |

set |

1 |

|

6 |

Three-color light |

set |

1 |

|

7 |

horizontal bridge |

Pcs |

1 |

|

8 |

Machine tool fixings |

set |

1 |

|

9 |

Standard Tool Package |

set |

1 |

|

10 |

security door lock |

set |

1 |

|

11 |

foundation kit |

set |

1 |

|

12 |

Install the adjustment tool |

set |

1 |

|

13 |

Rigid tapping and spindle multi-point positioning |

set |

1 |

|

14 |

Screw conveyor and automatic chip removal machine |

set |

1 |

|

15 |

Standard hydraulic system |

set |

1 |

Outsourcing parts configuration

|

Main accessories name |

Origin |

Brand |

Remark |

|

CNC system |

Germany |

Siemens |

Siemens 840DSL |

|

Spindle motor |

China |

Hao Zhi |

|

|

X, Y, Z axis servo motor |

Germany |

Siemens |

|

|

Spindle |

joint venture |

Brand Own |

Adopt German FAG bearing |

|

Spindle bearing |

Germany |

FAG |

|

|

Screw bearing |

Germany |

FAG |

|

|

Linear Guides |

Germany |

Rexroth |

UP-level accuracy |

|

Ball screw rod |

Taiwan |

HIWIN |

C3 grinding grade |

|

Hydraulic Components |

China |

Brand Own |

|

|

automatic lubrication system |

China |

Proton |

|

|

cooling system |

China |

Brand Own |

|

|

Lighting system |

China |

Owen |

|

|

warning light |

China |

Owen |

|

|

electric |

France Germany |

Schneider/Siemens |

|

|

Energy chain protection |

China |

Junhong |

|

|

Control wire cable |

Germany |

Lepurnani |

|

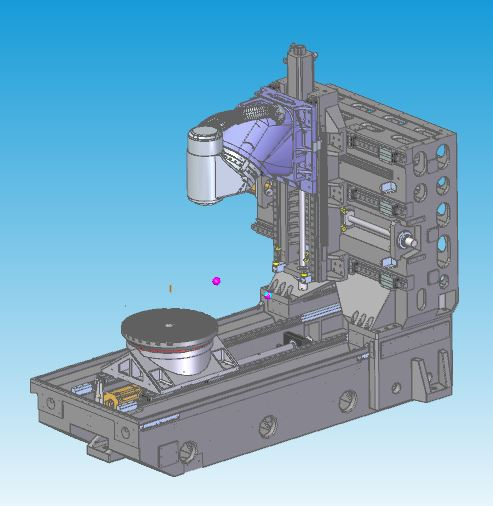

Main Machine Specifications | Optimum Rigid Structural Configuration

Design Features | Best Mechanical Wire Casting Analysis Design

Full box type thermosymmetric casting structure, using Meehanna grade high-grade cast iron

Tempering and natural aging treatment to eliminate internal stress

Structural natural frequency vibration eliminates material processing stress

Large-area high-rigidity column design with full wall, effectively improving rigidity and static and dynamic accuracy

Three-axis hollow cooling screw drive

CNC swing milling head (B axis)

Design Features

Built-in DD motor zero transmission chain no backlash design

High acceleration characteristics

The shortest span between the tool nose point of the spindle and the structural support point realizes the maximum rigidity of cutting

Larger YRT bearings increase rigidity

Equipped with HEIDENHAIN high-precision rotary encoder measurement system, fully closed-loop control to ensure the best accuracy

spindle and B-axis cooling system design to reduce heat transfer

Rotary table (C axis)

Design Features

Built-in DD motor zero transmission chain no backlash design

High acceleration and deceleration response characteristics

Larger YRT bearings increase rigidity

Large rated driving torque, positioning and processing with table positioning and clamping device

Meet the two processing needs of milling and milling-turning, reduce workpiece handling and improve product accuracy

Equipped with HEIDENHAIN high-precision rotary encoder measurement system, fully closed-loop control to ensure the best accuracy

Cooling system design to reduce heat transfer

Liftable tool setter

Design Features

Equipped with Ransishaw NC4F230 non-contact laser tool setter for higher precision

Automatic tool setting on machine, automatic update of tool compensation

The tool setting device can be raised and lowered to save the space of the processing surface

Fully sealed sheet metal design protects the tool setter from water and iron filings during processing

Infrared probe

Design Features

Equipped with Ransishaw OMP60 optical touch probe

On-machine workpiece alignment and size inspection, reduce manual inspection errors, improve product accuracy and processing efficiency

90% savings in on-machine assistance time

Safety protection sheet metal