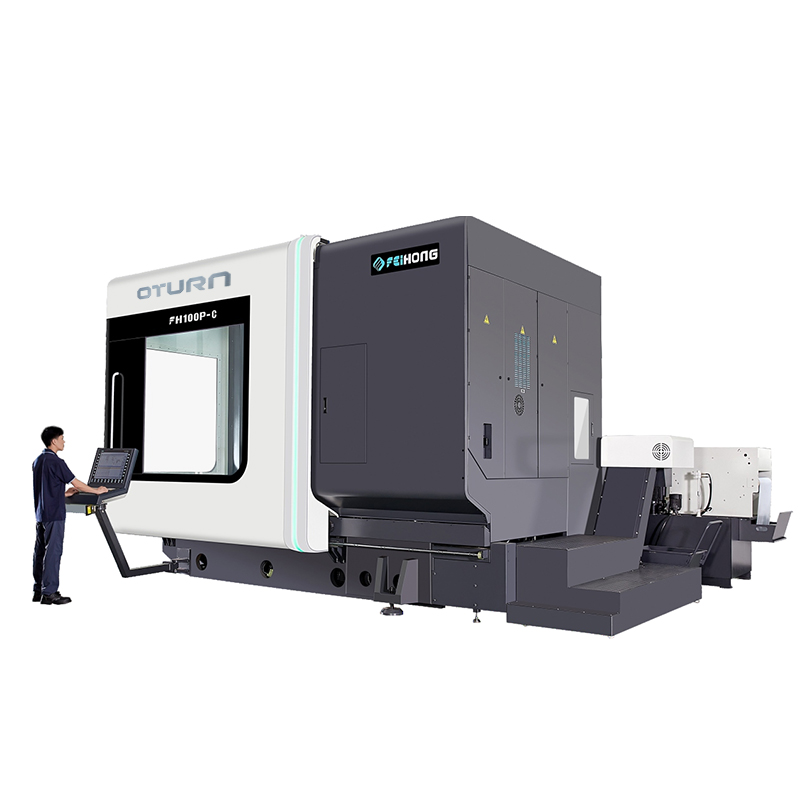

China Gate Valve Lathe Manufacturer for Precision Engineering Solutions

When I think about high-quality gate valve lathes, I immediately consider the precision and durability that our products offer. Sourced from a reputable manufacturer in China, our gate valve lathes are designed to meet the demanding needs of various industries. I know how crucial it is for B2B purchasers to have reliable equipment that can withstand rigorous usage while providing excellent performance. Each lathe is crafted with attention to detail, ensuring that it delivers consistent results with every project. The robust construction minimizes downtime, helping your operations run smoothly and efficiently. Plus, our competitive pricing makes it easier for you to find the right balance between quality and cost. If you’re in the market for a dependable gate valve lathe, I invite you to explore our selection. You'll find that our commitment to quality and customer satisfaction sets us apart in the industry. Let’s enhance your manufacturing capabilities together!

Gate Valve Lathe Dominates From Concept to Delivery

In today's competitive industrial landscape, the demand for high-quality gate valves has never been higher. The gate valve lathe plays a pivotal role in the manufacturing and delivery process, ensuring precision and efficiency from the initial concept to the final product. Advanced lathe technology enables manufacturers to produce gate valves that meet stringent quality standards, cater to various application requirements, and conform to international standards. This process not only streamlines production but also enhances overall product performance, making it an essential focus for global procurement specialists. When sourcing gate valves, it is crucial to consider the entire lifecycle of the product. From design and material selection to machining and finishing, each step influences the valve's durability and functionality. By leveraging state-of-the-art lathe technology, manufacturers can optimize these processes, resulting in products that not only meet but exceed customer expectations. Additionally, a well-structured supply chain ensures timely deliveries, enabling clients to maintain their operational schedules and avoid costly downtimes. Investing in gate valve solutions crafted with the latest lathe operations equips procurement professionals with robust tools that enhance their offerings in various sectors, including oil and gas, water treatment, and power generation. The integration of innovation in manufacturing not only solidifies a competitive edge but also fosters long-term partnerships that are built on reliability and excellence. As global markets evolve, embracing these advancements is key to securing a sustainable future.

Gate Valve Lathe Dominates From Concept to Delivery

| Feature | Specification | Material | Application | Delivery Time |

|---|---|---|---|---|

| Maximum Diameter | 600 mm | Carbon Steel | Oil & Gas | 4 weeks |

| Pressure Rating | PN16 | Stainless Steel | Chemical Industry | 6 weeks |

| Size Range | DN50 to DN600 | Ductile Iron | Water Supply | 5 weeks |

| Operating Temperature | -20 to 120 °C | Bronze | HVAC Systems | 3 weeks |

Related Products