CNC Sheet Drilling Machine Manufacturer in China for Precision Solutions

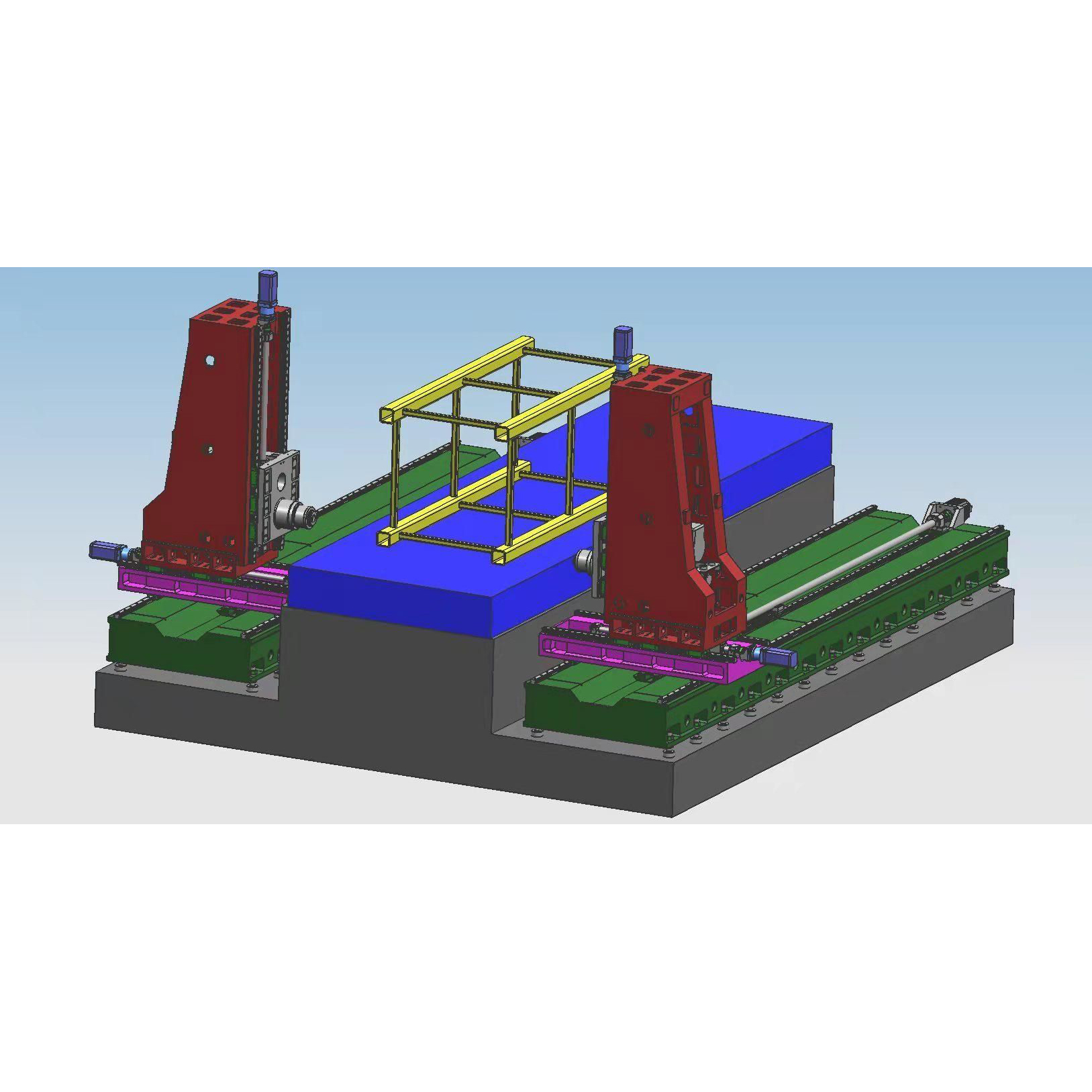

As a professional in the industry, I understand the importance of precision and efficiency in manufacturing. The CNC Sheet Drilling Machine we offer is designed to enhance your production capabilities, making it an essential investment for your operations. Manufactured in China, this machine boasts advanced technology that ensures accuracy and reliability for all your drilling needs. I’ve witnessed firsthand how our CNC machines streamline processes, resulting in reduced production times and enhanced product quality. Built with durability in mind, they can handle various sheet materials effortlessly. Our commitment to excellence is reflected in the positive feedback we receive from satisfied clients. Whether you’re a small business or a large manufacturer, our CNC Sheet Drilling Machine can adapt to your specific requirements. I invite you to explore the benefits of working with a trusted manufacturer like us, ensuring that you stay competitive in today’s fast-paced market. Let's elevate your production together!

Cnc Sheet Drilling Machine Trusted by Pros Factory-Direct Excellence

In the fast-paced world of manufacturing, efficiency and precision are paramount. For global procurement professionals seeking cutting-edge machinery, CNC sheet drilling machines stand out as indispensable tools that elevate production capabilities. Trusted by industry experts, these machines offer unparalleled accuracy and speed, enabling businesses to streamline operations and enhance product quality. The allure of factory-direct excellence means that buyers can expect not only superior performance but also competitive pricing and reliable customer support, making these machines a wise investment for any manufacturer. CNC sheet drilling machines are designed with advanced technology that simplifies complex drilling tasks, ensuring consistent results with minimal human intervention. This automation leads to reduced labor costs and lower error rates, which are critical in maintaining a competitive edge in a global market. The versatility of these machines allows them to handle various materials, catering to diverse industries such as aerospace, automotive, and construction. Furthermore, with ongoing technological advancements, many units now come equipped with software solutions that facilitate seamless integration into existing production lines, enhancing overall workflow efficiency. For procurement professionals, sourcing a CNC sheet drilling machine involves more than just comparing specifications; it’s about finding a partner that understands the unique challenges of the manufacturing landscape. By investing in trusted machinery, companies position themselves for growth, ensuring they can meet increasing demand while maintaining high standards. As the industry evolves, the importance of reliable, efficient equipment cannot be overstated, making it imperative for businesses to align with manufacturers that prioritize innovation and customer satisfaction.

Cnc Sheet Drilling Machine Trusted by Pros Factory-Direct Excellence

| Feature | Description | Benefit | Application |

|---|---|---|---|

| High Precision | Accurate drilling with minimal tolerances. | Ensures quality in finished products. | Aerospace, automotive, electronics. |

| Durable Construction | Built with high-quality materials for longevity. | Reduces maintenance costs. | Manufacturing environments. |

| User-Friendly Interface | Intuitive controls for easy operation. | Increases productivity and reduces training time. | Small to large workshops. |

| Automatic Tool Change | Seamlessly switches between tools. | Saves time during production cycles. | High-volume production lines. |

| Versatile Compatibility | Compatible with various sheet materials. | Ideal for diverse projects. | Metal, wood, plastics. |

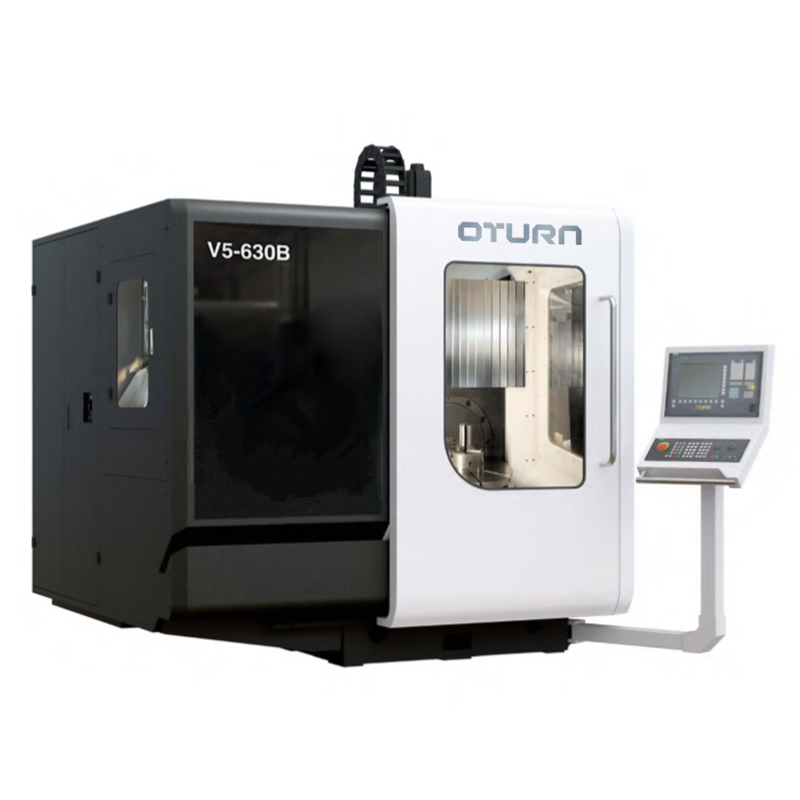

Related Products