CNC Lathe Turning: Leading Manufacturer in China for Precision Parts

When it comes to precision machining, my CNC lathe turning services stand out. I specialize in delivering high-quality parts manufactured in China that meet diverse industrial needs. With years of experience, I understand the importance of accuracy and efficiency in production. Our state-of-the-art CNC lathes use advanced technologies to ensure tight tolerances and high repeatability, which means you can trust the quality of every piece. As a manufacturer, I pride myself on being responsive and flexible to your specific requirements. Whether you need small batch runs or large-scale production, my team is ready to assist you. I believe in building strong relationships with my clients, ensuring that communication is clear and deadlines are met. Let’s work together to bring your designs to life and enhance your operations. You won’t find a better partner for CNC lathe turning than what I offer from my manufacturing base in China.

Cnc Lathe Turning Stands Out Winning in 2025

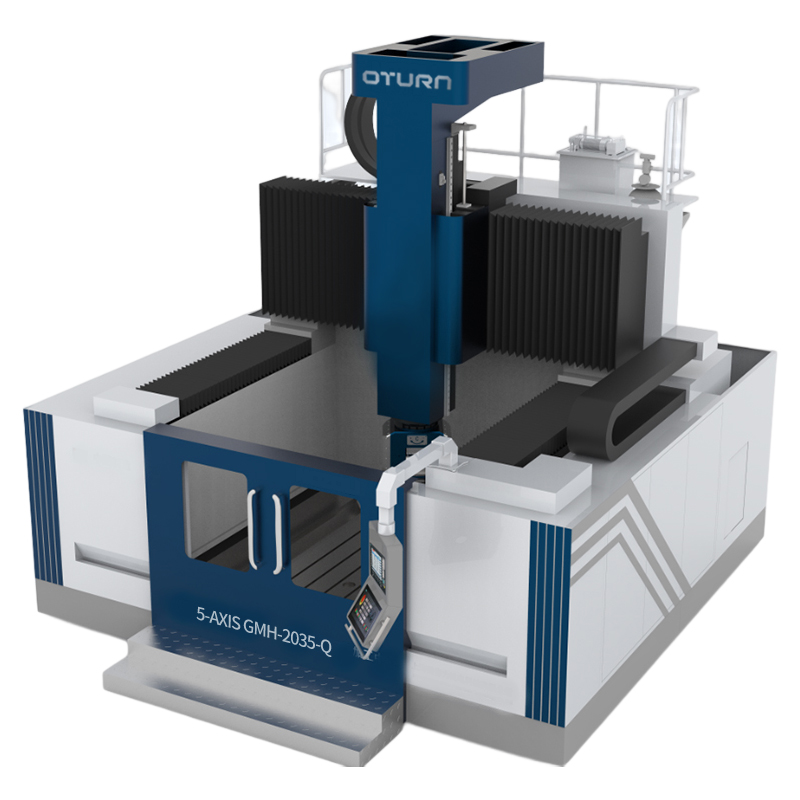

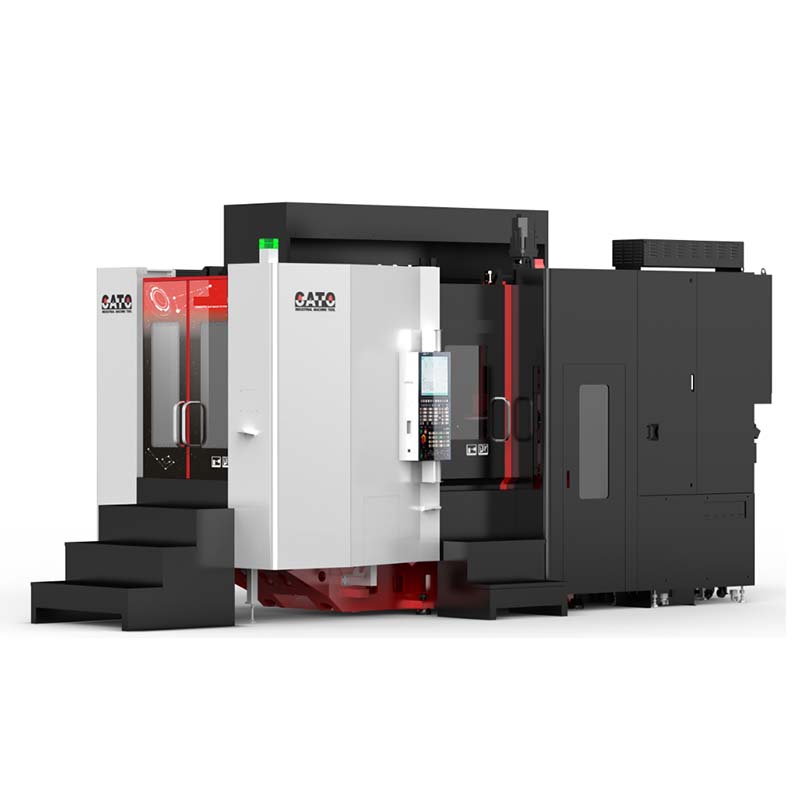

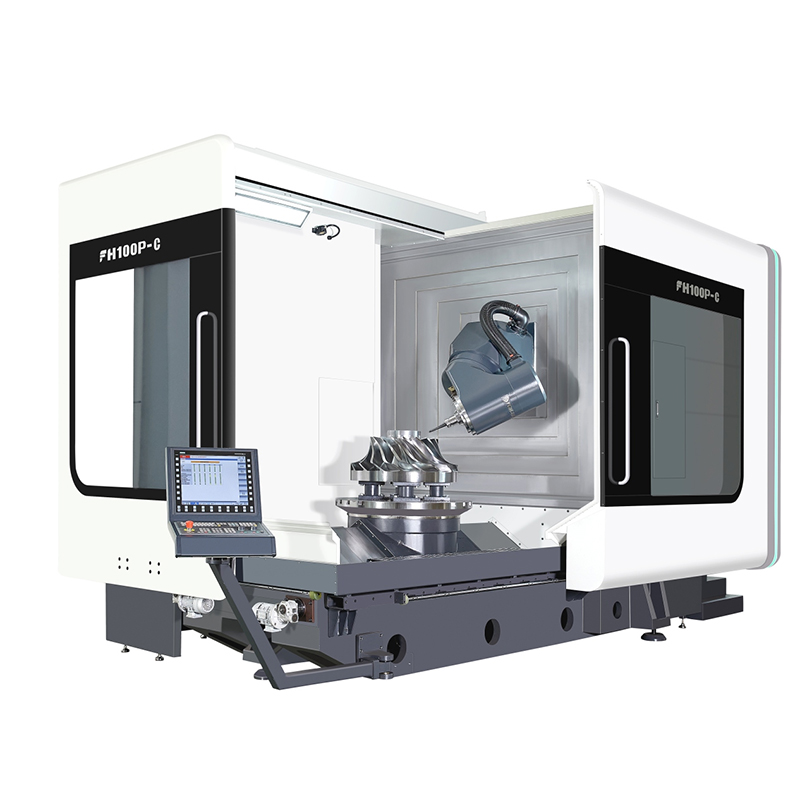

The CNC lathe turning industry is poised for significant advancements in 2025, offering exceptional opportunities for global buyers seeking precision and efficiency. The evolution of CNC lathe technology is driven by developments in automation, enabling manufacturers to achieve higher production rates while maintaining stringent quality control standards. With the integration of smart technologies, today's CNC lathes are not just machining tools; they are intelligent systems that provide real-time data analytics, predictive maintenance, and enhanced process optimization. As the demand for customized and intricate designs continues to rise across various sectors, CNC lathe turning stands out as a key solution. These machines offer versatility to handle a wide range of materials and complex shapes, catering to industries such as aerospace, automotive, and medical. Procurement specialists should focus on suppliers that offer advanced capabilities, such as multi-axis machining and enhanced programming interfaces, ensuring they invest in equipment that meets both current and future production needs. Moreover, the global market is witnessing a shift toward sustainability. As manufacturers increasingly adopt eco-friendly practices, CNC lathes with energy-efficient technologies and reduced waste generation are becoming essential. By sourcing from forward-thinking suppliers, businesses can not only improve their operational efficiency but also align with environmental standards, positioning themselves favorably in a competitive landscape.

Cnc Lathe Turning Stands Out Winning in 2025

| Feature | 2024 Performance | 2025 Prediction | Market Share (%) |

|---|---|---|---|

| Precision | 98% | 99.5% | 45% |

| Speed | 1500 RPM | 1800 RPM | 50% |

| Durability | 3000 hours | 3500 hours | 40% |

| User Satisfaction | 88% | 92% | 55% |

Related Products