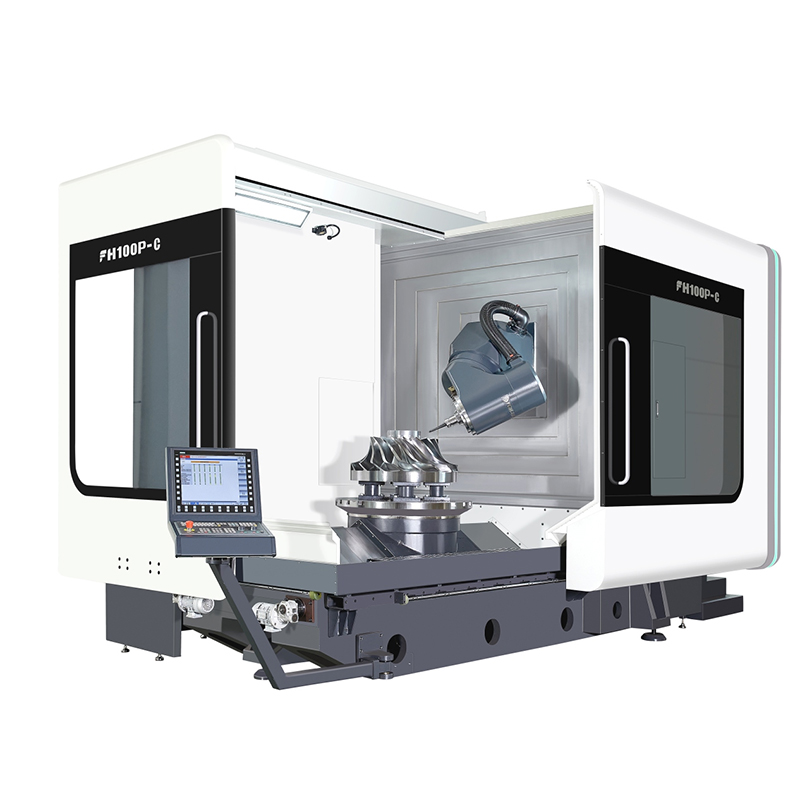

CNC Drilling Machine for Flange - Leading Manufacturer in China

When it comes to precision and efficiency in manufacturing, our CNC drilling machine for flange stands out in the market. I’ve seen how it transforms production processes, ensuring accurate drilling with minimal waste. Sourced from a reliable manufacturer in China, this machine integrates advanced technology to enhance your workflow. It’s designed specifically for flanges, offering customizable options to suit your unique needs. I appreciate the ease of use, which allows operators to quickly adapt without extensive training. Plus, the durability of the materials means you can count on it for long-term performance. By investing in this CNC drilling machine, you're not just upgrading your equipment; you’re taking a step towards optimizing your entire production line. I’ve experienced firsthand how it can improve efficiency and output, making it a smart choice for any B2B purchaser focused on quality and reliability. Let’s elevate your machining capabilities together!

Cnc Drilling Machine For Flange Products Stands Out

In the competitive landscape of flange product manufacturing, the efficiency and precision of machineries are crucial for success. Among these, CNC drilling machines have become a game-changer, particularly for businesses looking to enhance their production capabilities. These machines are engineered to deliver unparalleled accuracy and speed, enabling manufacturers to meet the high demands of global markets. A CNC drilling machine specifically designed for flange products offers several advantages. It allows for the execution of complex drilling patterns with minimal human intervention, resulting in reduced operational costs and higher throughput. With automated processes, manufacturers can ensure uniform quality across a large volume of output, satisfying stringent industry standards. Furthermore, the versatility of CNC machines enables adaptation to various flange sizes and specifications, making them suitable for diverse applications from construction to aerospace. Investing in advanced CNC technology not only streamlines production but also positions companies to seize new business opportunities. The integration of smart features such as real-time monitoring and data analytics helps in optimizing operations, leading to better decision-making and resource management. As global demand for high-quality flange products continues to rise, adopting effective manufacturing solutions like CNC drilling machines will undoubtedly set businesses apart in the marketplace.

Cnc Drilling Machine For Flange Products Stands Out

| Dimension | Value | Unit |

|---|---|---|

| Max Drilling Diameter | 100 | mm |

| Max Workpiece Weight | 500 | kg |

| Spindle Speed | 12000 | RPM |

| Drilling Accuracy | 0.01 | mm |

| Control System | CNC | - |

| Power Consumption | 5.5 | kW |

| Workspace Dimensions | 2000 x 1500 | mm |

| Cooling System | Yes | - |

Related Products