Automatic Lathe for Valve - Top Manufacturer in China

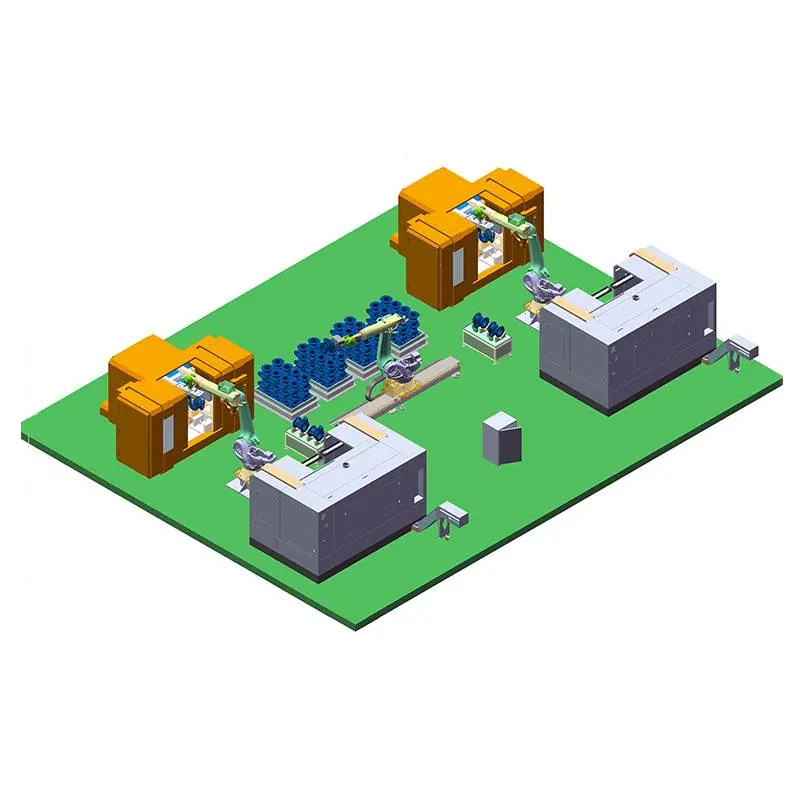

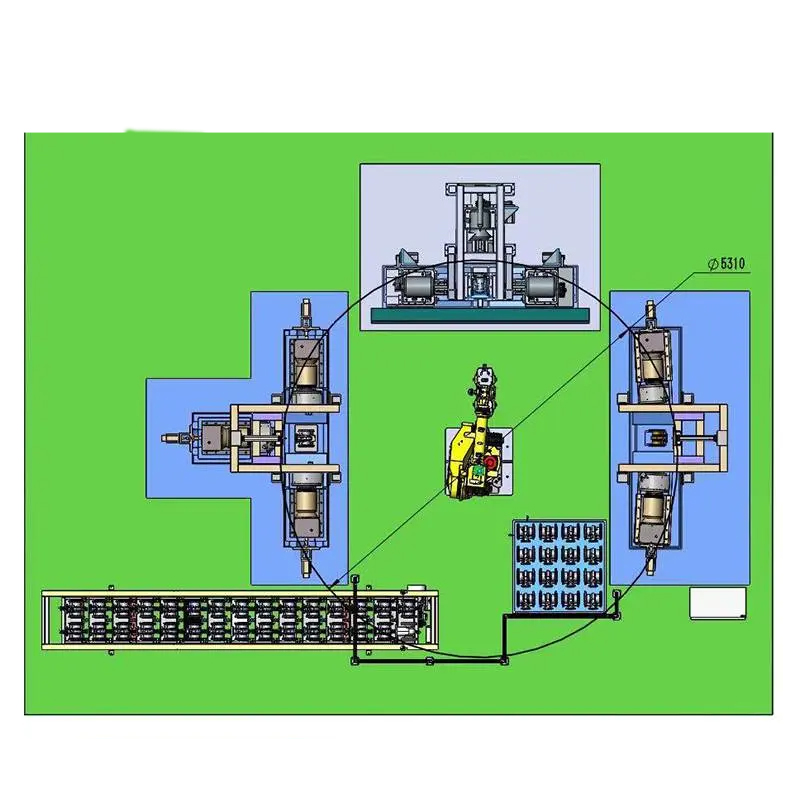

When it comes to precision machining, my Automatic Lathe for Valve stands out as a top choice for manufacturers looking to enhance their production efficiency. Designed to handle complex valve components, this machine offers exceptional accuracy and reliability, which is crucial for meeting the stringent demands of the industry. Based in China, we take pride in our advanced technology and skilled craftsmanship. We’ve spent years perfecting our manufacturing process to ensure that each lathe meets international quality standards while providing outstanding performance. Whether you're a small workshop or a large-scale operation, our automatic lathes are customizable to suit your specific needs. Investing in our Automatic Lathe for Valve not only boosts your production capabilities but also reduces operational costs. Let’s optimize your manufacturing process together and drive success in your business. Contact us today to learn more about how our products can benefit you!

Automatic Lathe For Valve Sets the Industry Standard Winning in 2025

In the rapidly evolving landscape of manufacturing, the introduction of automatic lathes specifically designed for valve sets is set to redefine industry standards. As we move toward 2025, the demand for precision, efficiency, and quality in valve production is more critical than ever. Automatic lathes offer unparalleled advantages, such as enhanced machining speed and reduced human error, enabling manufacturers to meet the rigorous standards of modern engineering demands. These advanced machines incorporate cutting-edge technology, allowing for seamless integration with automated production lines. This capability not only streamlines workflows but also significantly cuts down on production costs, providing businesses with a competitive edge in the global marketplace. For procurement professionals, investing in such machinery is essential for staying ahead of the curve, ensuring that their operations are not only efficient but also scalable to meet future demands. As we reflect on the journey towards 2025, embracing innovation in manufacturing processes will be paramount. The automatic lathe for valve sets stands at the forefront of this shift, enabling manufacturers to produce high-quality components more effectively than ever before. Adapting to these advancements will ensure that businesses remain relevant and competitive in a landscape characterized by rapid technological change.

Automatic Lathe For Valve Sets the Industry Standard Winning in 2025

| Feature | Details | Performance Metric |

|---|---|---|

| Precision | High precision machining capabilities with tolerances of ±0.01 mm | 98% accuracy rating |

| Material Compatibility | Suitable for various materials including stainless steel, brass, and plastic | Versatile usage across industries |

| Production Speed | Capable of automated production at a rate of 600 units per hour | Maximized throughput |

| User Interface | Intuitive touchscreen control panel with easy setup | Reduced operator training time by 30% |

| Energy Efficiency | Engineered for low energy consumption without sacrificing performance | 20% reduction in energy costs |

| Safety Features | Equipped with multiple safety sensors and emergency shutdown | Higher workplace safety ratings |

Related Products