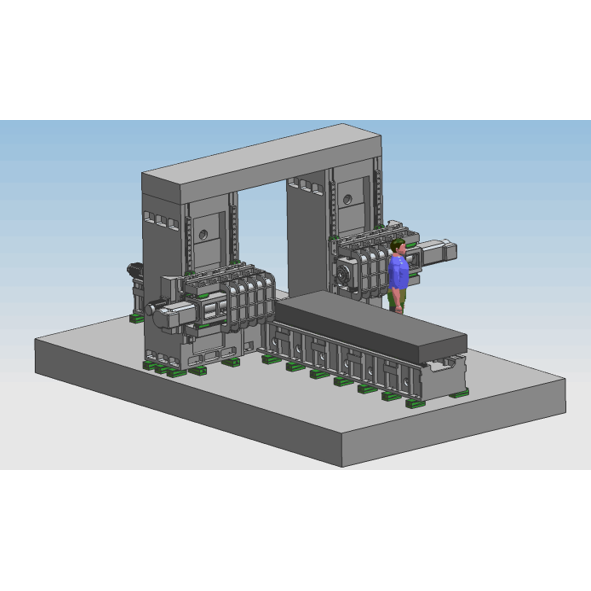

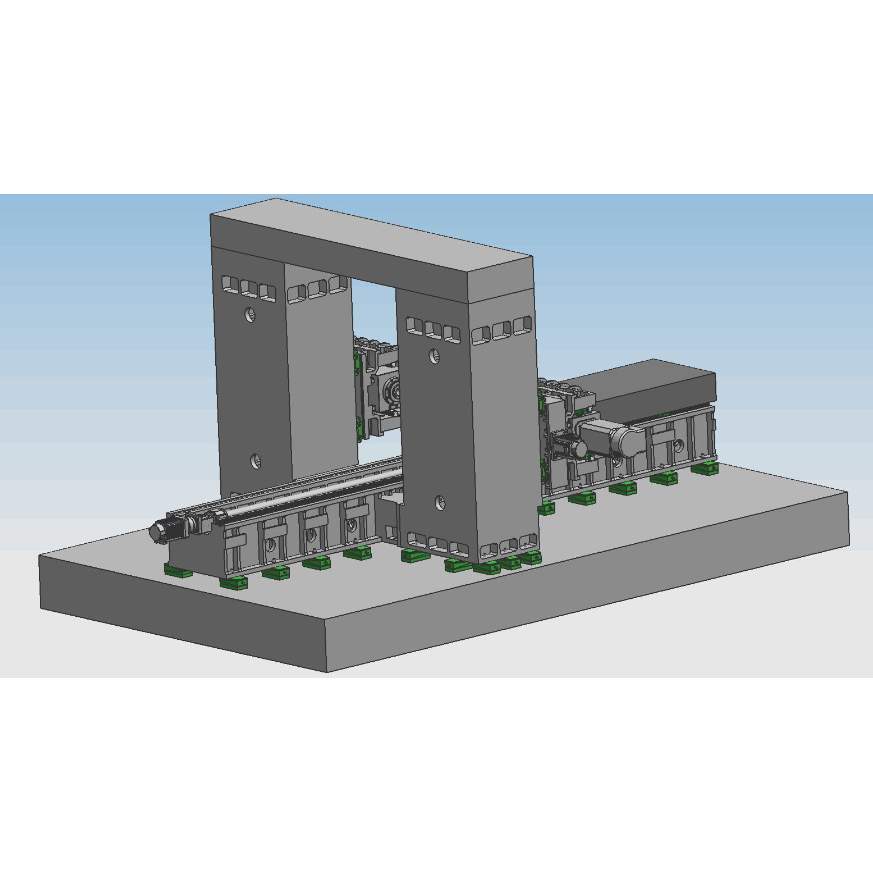

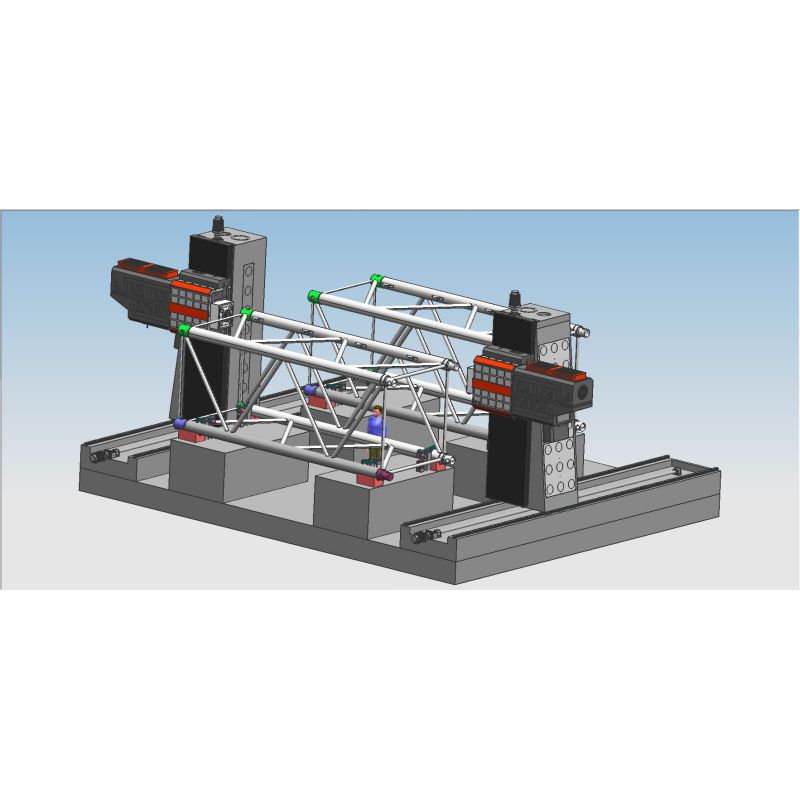

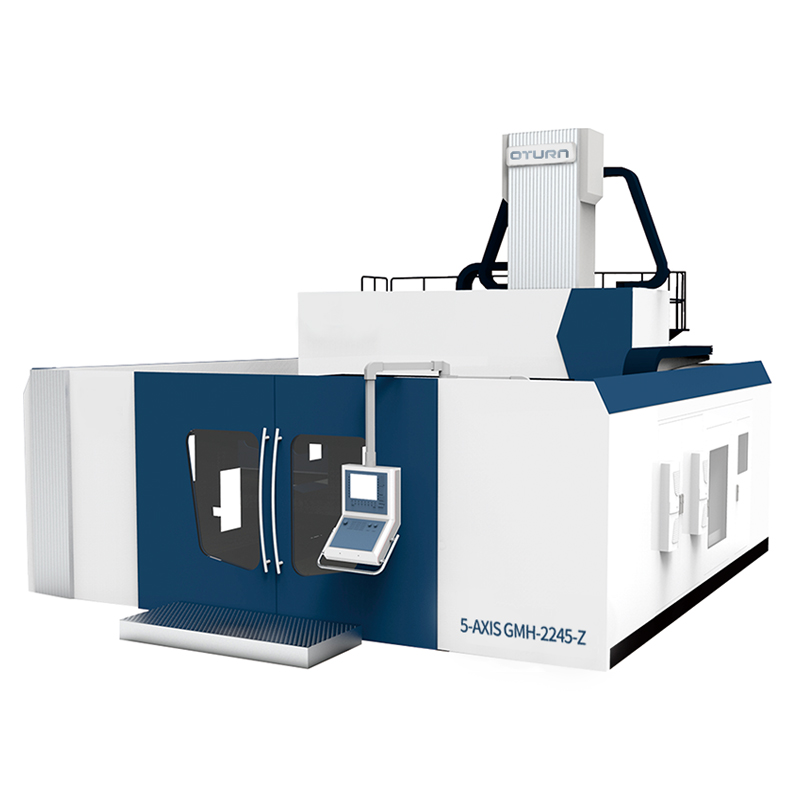

Top VMC CNC Milling Machines from Leading China Manufacturer

As a manufacturer of VMC CNC milling machines in China, I understand the importance of precision and efficiency in your operations. Our machines are designed with cutting-edge technology to ensure high performance and reliability, tailored to meet your specific manufacturing needs. With robust construction and user-friendly interfaces, these machines empower you to enhance productivity and produce high-quality components. I've seen firsthand how our VMC CNC milling machines can revolutionize your workflow, offering fast setup times and exceptional accuracy. Plus, we provide comprehensive support and training, so you can maximize the machine's potential from day one. If you aim to elevate your production capabilities, our VMC CNC milling machines could be the game-changer. Let’s connect to discuss how our solutions can fit into your business strategy and help you stay ahead in your industry. Your success is our priority, and I'm here to assist you every step of the way.

Vmc Cnc Milling Machine Service For the Current Year

In an increasingly competitive manufacturing landscape, maintaining peak efficiency and precision in operations is crucial. This year, investing in VMC CNC milling machine services can significantly enhance production capabilities and reduce operational downtime. These advanced machines offer versatility in handling complex tasks with unmatched precision, making them ideal for various industries, from aerospace to automotive. Ensuring your VMC CNC machines are serviced regularly can extend their lifespan, improve performance, and ultimately lead to cost savings. As you explore global procurement options, consider the importance of partnerships that prioritize quality service and customer support. A reputable service provider will not only offer maintenance and repairs but also be equipped to provide training and consultation, helping your team maximize the potential of your machinery. Adopting a proactive approach to machine servicing can drive efficiency and innovation in your production processes. As the demand for precision-engineered components continues to rise, prioritizing the service and maintenance of your VMC CNC milling machines is essential. Keep in mind that a reliable service ensures your machines run at optimal capacity, letting you meet production deadlines and quality standards. Investing in these services today can pave the way for increased productivity and competitive advantage in the global market.

Vmc Cnc Milling Machine Service For the Current Year

| Service Type | Frequency | Duration | Technician | Service Status |

|---|---|---|---|---|

| Preventive Maintenance | Monthly | 2 hours | John Doe | Completed |

| Software Update | Quarterly | 1 hour | Jane Smith | Pending |

| Calibration | Biannual | 3 hours | Michael Brown | Scheduled |

| Emergency Repair | As Needed | Variable | Emily Johnson | In Progress |

| Parts Replacement | As Needed | 1-2 hours | Sarah Davis | Completed |

Related Products