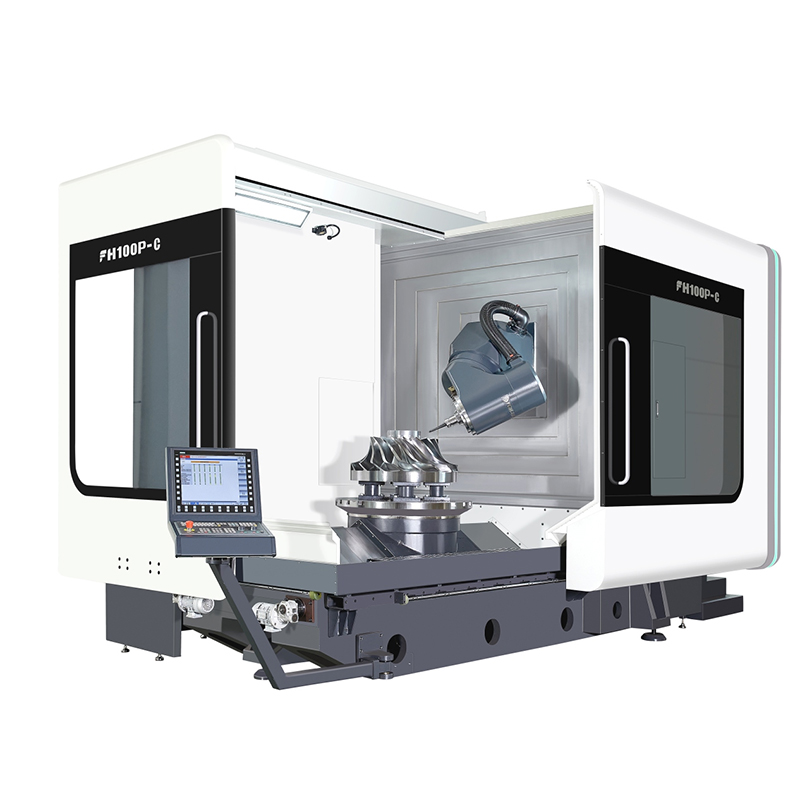

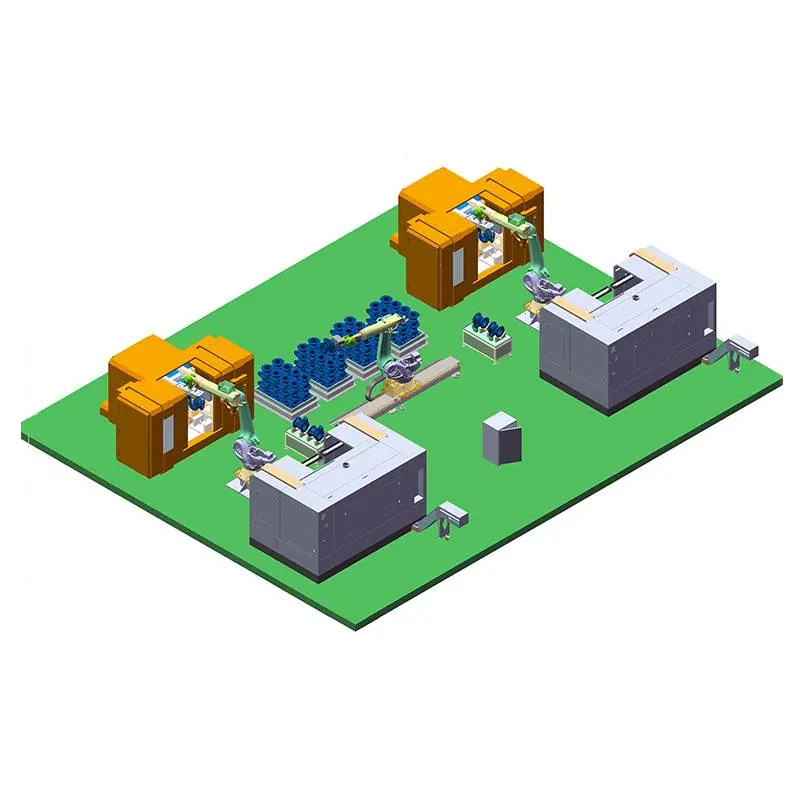

Cnc Vertical Turret Lathe - Manufacturers, Factory, Suppliers from China

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Cnc Vertical Turret Lathe, Conventional Vertical Lathe, Cnc Sheet Drilling Machine, Drive Turning Machine,Valve Special Machine. Our items have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. On the lookout ahead to make up a good and long-lasting cooperation with you in coming potential! The product will supply to all over the world, such as Europe, America, Australia,El Salvador, Finland,Nicaragua, Latvia.We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.