Vertical Turning Lathe Manufacturers in China for Precision Engineering

When it comes to precision and efficiency in machining, a Vertical Turning Lathe is a game changer. I understand that sourcing high-quality equipment is crucial for your business. That's why I’m excited to present our state-of-the-art Vertical Turning Lathes, manufactured right here in China. These lathes are designed to enhance productivity and ensure accuracy in every cut, helping you stay competitive in today’s market. With robust construction and user-friendly features, our Vertical Turning Lathes cater to various industries, offering reliability you can trust. Each machine is crafted with meticulous attention to detail, ensuring that you get the best performance for your investment. If you’re looking for a trusted manufacturer with a reputation for excellence, look no further. Let’s elevate your machining capabilities together!

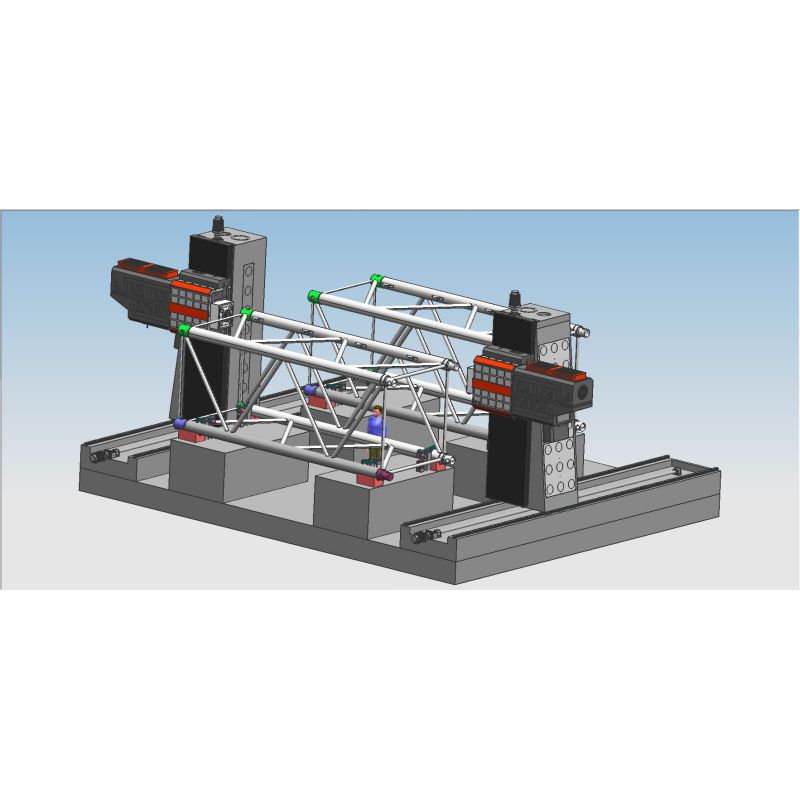

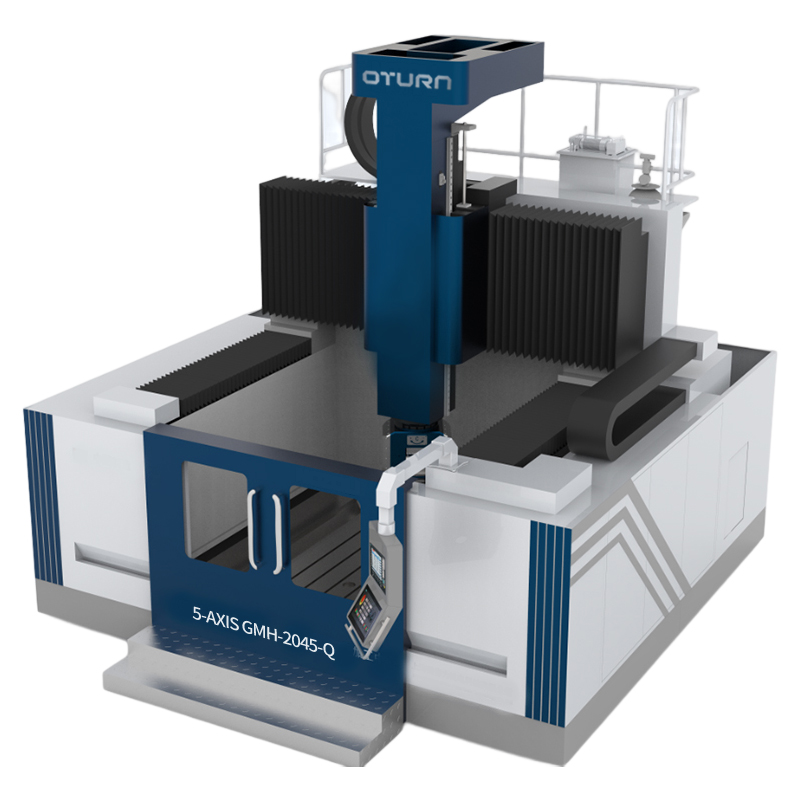

Vertical Turning Lathe Trusted by Pros Custom Solutions,

When it comes to precision machining, vertical turning lathes have emerged as a preferred choice among professionals in various industries. These machines excel in efficiently handling large and heavy workpieces, providing superior accuracy and surface finish compared to conventional lathes. For global buyers seeking reliable solutions for their manufacturing needs, investing in a robust vertical turning lathe can significantly enhance productivity and operational efficiency. Our vertical turning lathes are designed with advanced technology, ensuring they meet the rigorous demands of modern manufacturing environments. With customizable features and configurations, these machines can cater to specific production requirements, whether for aerospace components, automotive parts, or heavy machinery components. The ease of operation and maintenance further reduces downtime, making it a cost-effective choice for businesses looking to optimize their machining processes. In an increasingly competitive landscape, having the right equipment can set your business apart. By choosing a vertical turning lathe, you not only gain a trusted machine that delivers consistent results but also the flexibility to adapt to evolving market demands. Embrace innovation and elevate your manufacturing capabilities with a solution that professionals rely on.

Vertical Turning Lathe Trusted by Pros Custom Solutions

| Specification | Description | Applications | Materials |

|---|---|---|---|

| Max Turning Diameter | 1000 mm | Heavy Machinery Parts | Steel, Aluminum |

| Spindle Speed | 0 - 600 RPM | Aerospace Components | Titanium, Composites |

| Tool Holder Type | VDI System | Automotive Parts | Cast Iron, Brass |

| Control System | CNC | Marine Engineering | Stainless Steel |

| Weight Capacity | 2000 kg | Power Generation | High Carbon Steel |

Related Products