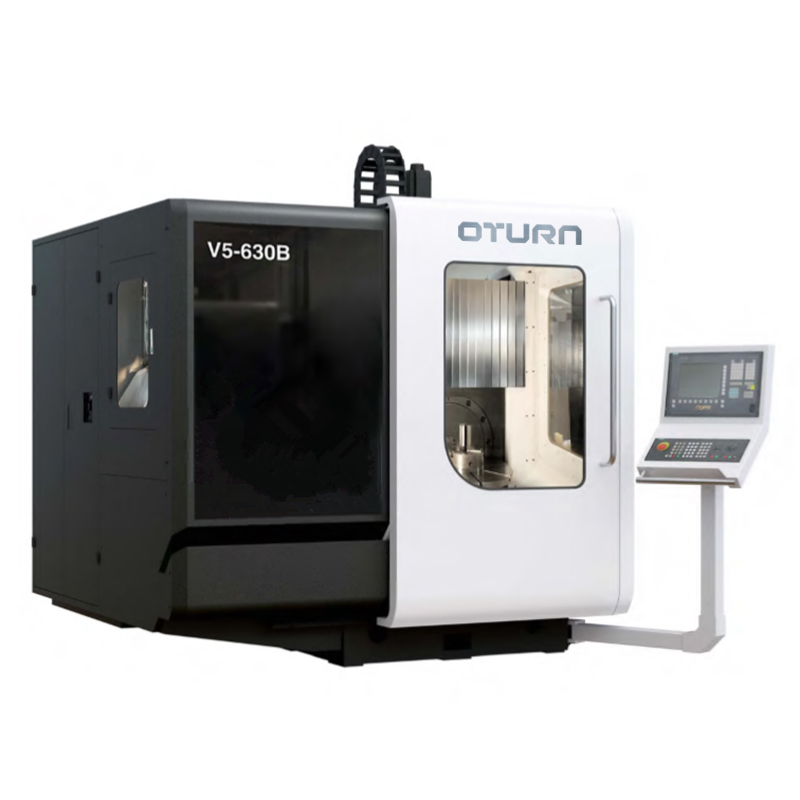

Top Valve Lathe Manufacturers in China: Quality and Innovation

When it comes to precision machining, my Valve Lathe stands out as a top choice for manufacturers in China. I’ve engineered this equipment to handle various materials with exceptional accuracy, meeting the demands of today’s industries. With a focus on durability and performance, this lathe ensures that you can produce high-quality valve components with ease. I understand that reliability is crucial for your projects, which is why my Valve Lathe is designed for efficiency and longevity. Its user-friendly interface simplifies operations, enabling your team to work faster and with improved precision. As a manufacturer committed to meeting international standards, I prioritize quality in every aspect of production. Choosing my Valve Lathe means investing in a solution that enhances productivity and reduces downtime. Let’s work together to elevate your manufacturing processes and achieve significant results with tools that truly make a difference.

Valve Lathe in 2025 Ahead of the Curve

As we look ahead to 2025, the valve lathe stands as a pivotal tool in the precision machining industry. With advancements in technology and the increasing demand for high-quality valve components, manufacturers must adapt to remain competitive. The valve lathe is engineered to deliver exceptional machining capabilities, ensuring that businesses can produce valves with precision and efficiency. By leveraging the latest innovations, manufacturers can streamline their production processes, reduce waste, and ultimately enhance product quality. In a global marketplace that prioritizes speed and cost-effectiveness, investing in state-of-the-art valve lathes is crucial. These machines not only improve operational efficiency but also enable manufacturers to respond swiftly to changing market demands. As industries worldwide evolve, the ability to produce customized solutions will set companies apart from their competitors. Moreover, with environmental regulations becoming increasingly stringent, modern valve lathes are designed to minimize energy consumption and reduce environmental impact, making them a sustainable choice for businesses. The future of machining lies in embracing cutting-edge technology, and the valve lathe is at the forefront of this transformation. For global procurement professionals, investing in advanced machining solutions is a strategic move to ensure long-term success. As we approach 2025, understanding the capabilities and advantages of modern valve lathes will be essential for staying ahead of the curve and meeting the rising expectations of customers across diverse sectors.

Valve Lathe in 2025 Ahead of the Curve

| Feature | Specification | Application | Innovation |

|---|---|---|---|

| Precision Cutting | ±0.01 mm | Aerospace Components | AI Optimization |

| Material Compatibility | Steel, Aluminum, Titanium | Automotive Industry | Smart Sensors |

| User Interface | Touchscreen Display | Medical Device Manufacturing | Gesture Control |

| Environmental Impact | Low Emissions | Renewable Energy Components | Energy Recovery Systems |

Related Products