An old customer from Turkey introduced a customer who processed pipes.They like European high-quality CNC pipe threading lathes very much with high price.After they talked with us and then they realized their wrong idea,the European machine is not the best choice for them.

In fact, to a certain extent, our CNC pipe threading lathes are not inferior to European machines. For the processing of many workpieces, such high-precision and high-tech machines are not actually required.

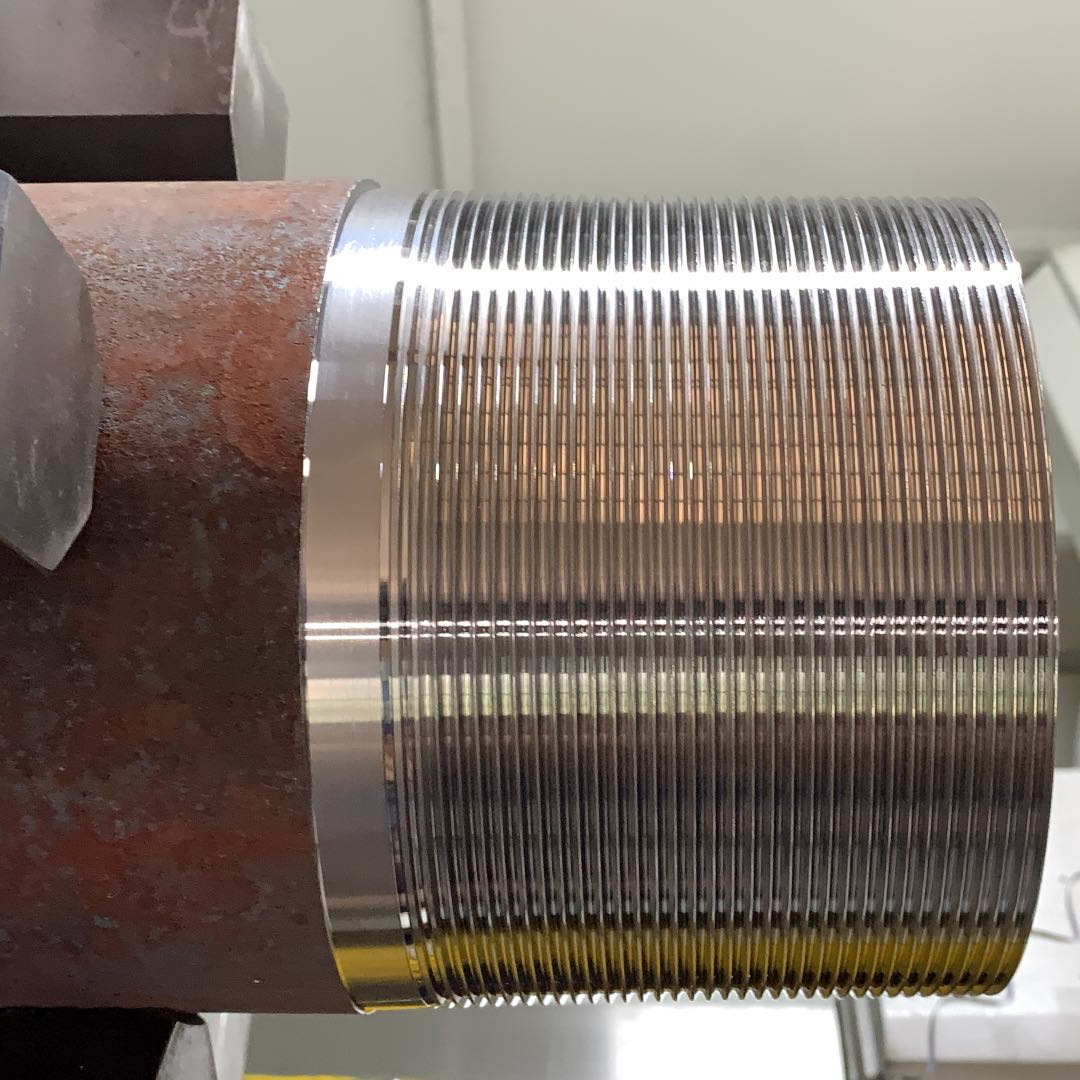

The machining accuracy of the pipe fittings to be processed by the customer is only 0.05mm, and the machining accuracy of our CNC pipe threading lathe can reach 0.02mm.The diameter range of the workpiece is within 250mm, we recommend QLK1325.

Most of the models on the market now are QLK1323 and QLK1328.

Our engineers realized that QLK1323 is not big enough for φ250mm workpieces, QLK1328 is too big and the price is too high. So our engineers developed the QLK1325 model, which is supported and loved by many customers.

Another problem is that the customer’s pipe fitting length range is very large. The shortest pipe is only 1.5 meters, but the longest can reach six meters.We recommend two options.

One is to choose a three-meter CNC pipe threading lathe for processing, which can rotate the workpiece 180° to complete the processing of both ends on the machine.

Another solution is to choose a six-meter CNC pipe threading lathe for one-time clamping and finishing.

Obviously the second solution is very efficient and saves labor costs. But if the budget is insufficient, the first option will be a better choice.The customer chose the first solution with the idea of giving it a try. The customer chose a three-meter CNC pipe threading lathe QLK1325 with a rear support.Now the machine has been put into use and the customer is very satisfied.

Post time: Oct-11-2021