Top China Manufacturer of Special Purpose Machines for Valves

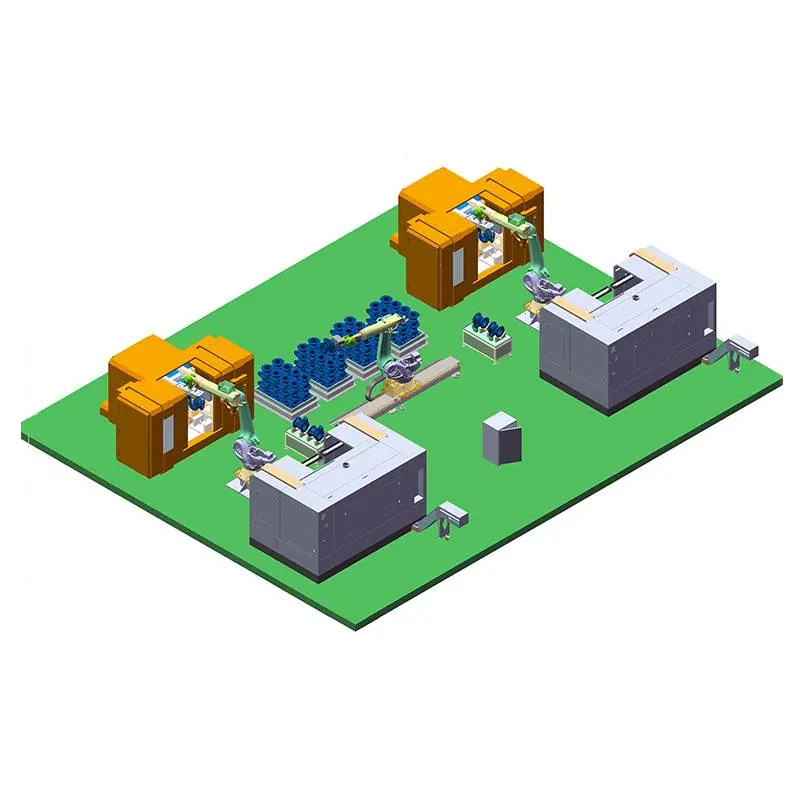

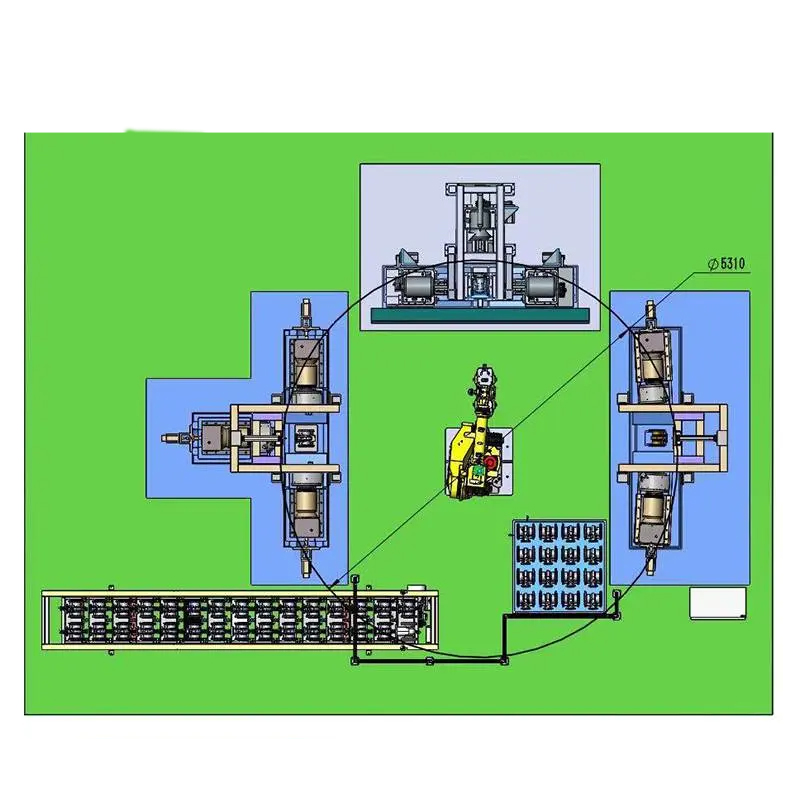

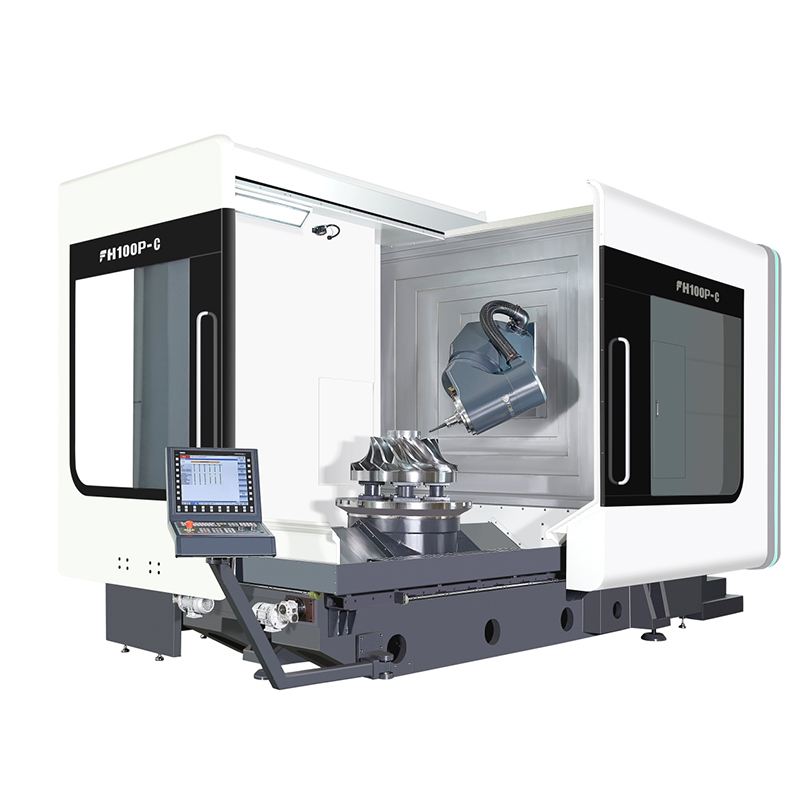

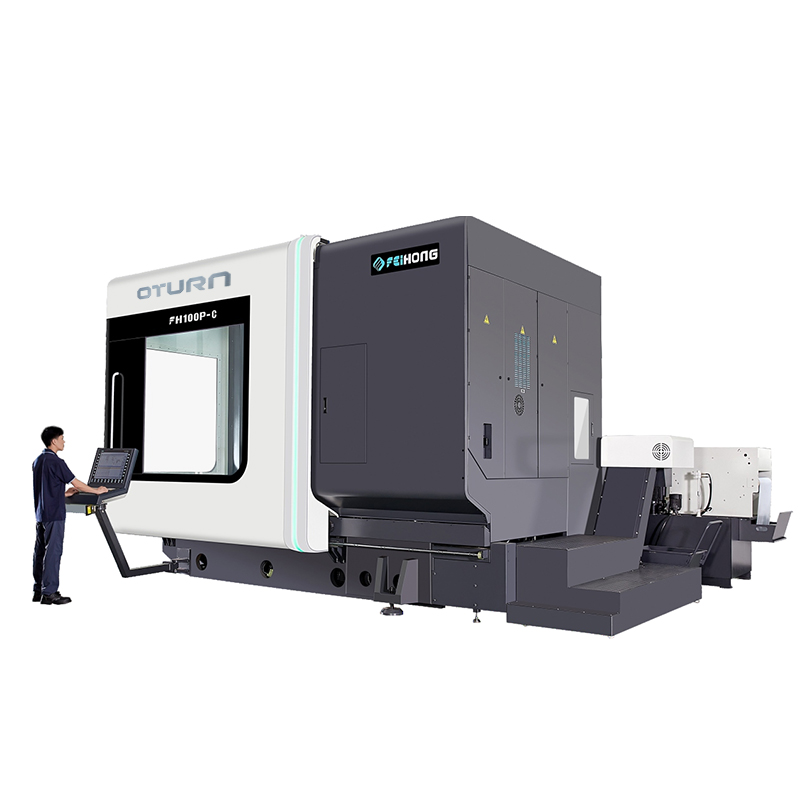

When it comes to enhancing your production line, our Special Purpose Machine for Valve stands out in the manufacturing sector in China. I’ve seen firsthand how these machines can revolutionize your operations, making valve production more efficient and precise. Whether you're a small workshop or a large-scale manufacturer, this machine caters to your specific needs, adapting to various valve designs. Our commitment to quality ensures that each unit is built to last, with robust materials and innovative technology. I remember a client who doubled their output after integrating our machine into their workflow – it was a game changer! As a reliable manufacturer based in China, we focus on not just machines, but also long-term partnerships. We ensure prompt support and service, helping you optimize your production processes. Let’s take your valve manufacturing to the next level together!

Special Purpose Machine For Valve Dominates Exceeds Industry Benchmarks

In the competitive landscape of industrial machinery, specialized equipment for valve manufacturing has taken center stage, showcasing innovations that exceed conventional industry benchmarks. The latest advancements in special purpose machines for valves have demonstrated unparalleled efficiency, precision, and adaptability, making them a vital asset for manufacturers aiming to optimize their production processes. These machines not only streamline operations but also enhance product quality, positioning companies at the forefront of the valve industry. What sets these special purpose machines apart is their ability to integrate advanced technology, such as automation and real-time monitoring, allowing for the precise control of manufacturing parameters. As global demand for high-quality valves rises, so does the importance of investing in machinery that delivers consistent results while reducing waste and production time. This commitment to excellence not only meets buyer expectations but also opens new avenues for market expansion and competitiveness. Ultimately, investing in specialized machinery for valve production is not just about staying relevant; it's about leading the charge in a rapidly evolving industrial sector. For procurement specialists searching for high-performance solutions, understanding the unique capabilities of these machines can be the key to unlocking new efficiencies and driving growth in their operations, ensuring they remain ahead in the global market.

Special Purpose Machine For Valve Dominates Exceeds Industry Benchmarks

| Parameter | Value | Industry Benchmark | Exceeds Standard |

|---|---|---|---|

| Production Speed (units/hour) | 120 | 100 | Yes |

| Precision (mm) | 0.05 | 0.1 | Yes |

| Operational Efficiency (%) | 95 | 85 | Yes |

| Energy Consumption (kWh/unit) | 2.0 | 2.5 | Yes |

| Maintenance Interval (hours) | 500 | 300 | Yes |

Related Products