Top Milling Machine Manufacturers in China: Quality & Innovation

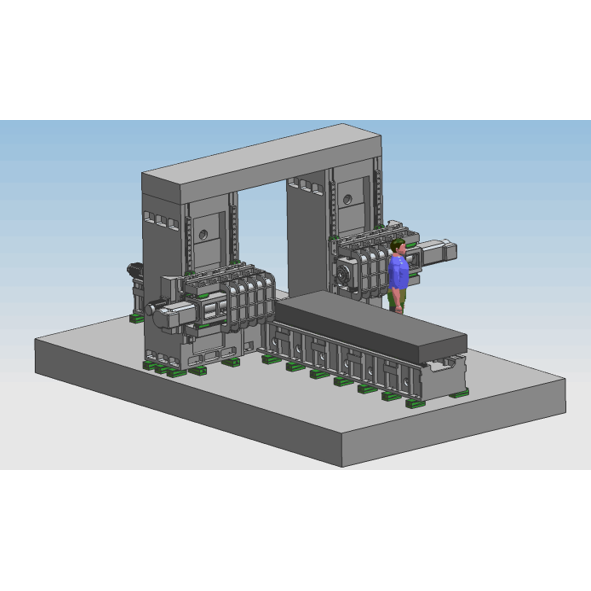

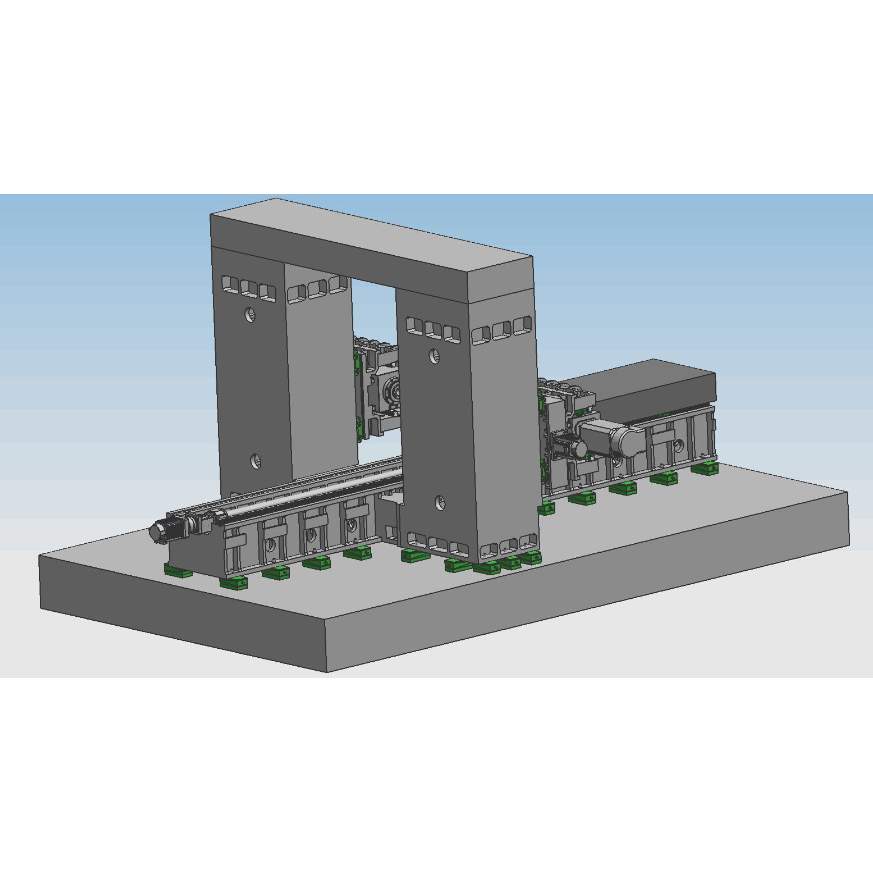

As a B2B purchaser, I know how crucial it is to find the right milling machine that meets all my manufacturing needs. Sourcing from China has its advantages, especially when it comes to high-quality machinery at competitive prices. The milling machines I’ve encountered from reputable manufacturers there are built to last, incorporating advanced technology to boost productivity. With options tailored to various industries, it feels like I have endless possibilities for my projects. Understanding how these machines operate helps me select the best fit for my business. From precision milling to robust construction, the performance of these machines is unmatched, and they come with essential features that promote efficiency. Collaborating with a trusted Chinese manufacturer means reliable support and parts availability, making my investment worthwhile. If you're in the market for a milling machine that won’t let you down, exploring options from China could really elevate your operations.

Milling Machine in 2025 Pioneers in the Field

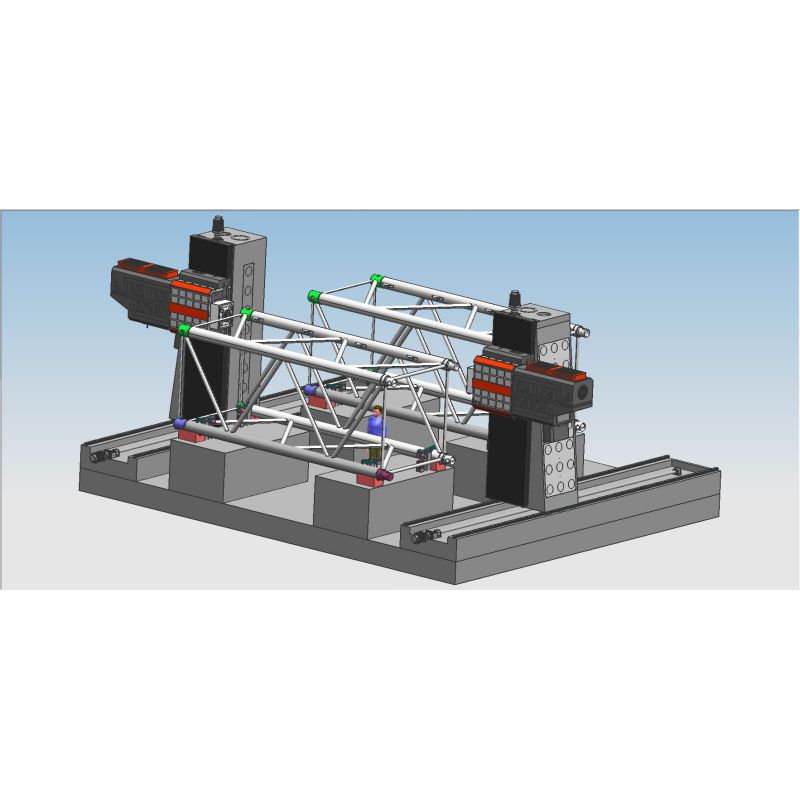

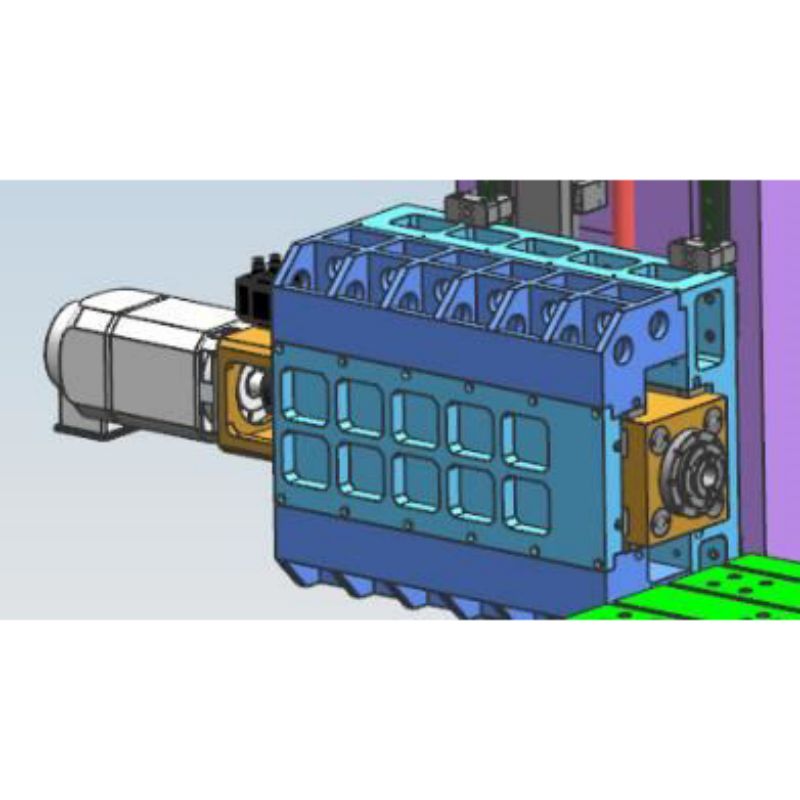

As we approach 2025, the milling machine industry is witnessing significant advancements driven by technological innovations and evolving market demands. Manufacturers are increasingly adopting automation and smart technologies to enhance productivity, efficiency, and precision in milling processes. The integration of AI and IoT solutions allows for real-time monitoring and data analysis, leading to optimized operations and reduced downtime. This shift not only boosts the performance of milling machines but also helps manufacturers meet the rising expectations for quality and speed in production. Moreover, sustainability is becoming a key focus in the milling machinery sector. Companies are seeking eco-friendly solutions that minimize material waste and energy consumption. The exploration of advanced materials and energy-efficient designs ensures that milling machines can operate with a smaller environmental footprint, catering to the global emphasis on sustainable manufacturing practices. As international trade dynamics evolve, businesses must adapt to these trends to stay competitive in the burgeoning global market. In this rapidly changing landscape, global buyers are encouraged to explore partnerships with pioneers who are at the forefront of these innovations. Selecting equipment that complies with the latest industry standards and showcases cutting-edge features will be essential for enhancing production capabilities and achieving success in the competitive milling industry of 2025. By prioritizing quality, efficiency, and sustainability, forward-thinking companies can position themselves advantageously in a world where manufacturing excellence is paramount.

Milling Machine in 2025 Pioneers in the Field

| Model | Motor Power (kW) | Table Size (mm) | Weight (kg) | Features |

|---|---|---|---|---|

| Model X1 | 5.5 | 1200 x 600 | 1500 | CNC Control, High Precision |

| Model Y2 | 7.5 | 1500 x 800 | 2200 | Multi-function, Auto Tool Change |

| Model Z3 | 11 | 2000 x 1000 | 3000 | High-Speed, Intelligent Monitoring |

Related Products