Lathe Machine for Valve - Top China Manufacturer Quality Solutions

Are you in the market for a reliable lathe machine for valve manufacturing? Look no further. Our lathe machines, sourced directly from trusted manufacturers in China, offer precision and durability tailored for valve production. I’ve seen firsthand how these machines dramatically enhance efficiency and accuracy, reducing production times while maintaining top-notch quality. With advanced technologies integrated into our lathes, you can tackle even the most complex valve designs without breaking a sweat. Whether you’re a small workshop or a large factory, our machines cater to various production needs. I can personally vouch for the robust construction and user-friendly features, making it a smart investment for your manufacturing operations. Don't miss out on the chance to elevate your production line. Reach out today, and let's discuss how our lathe machine can meet your specific requirements, ensuring you stay competitive in the market.

Lathe Machine For Valve Application From Concept to Delivery

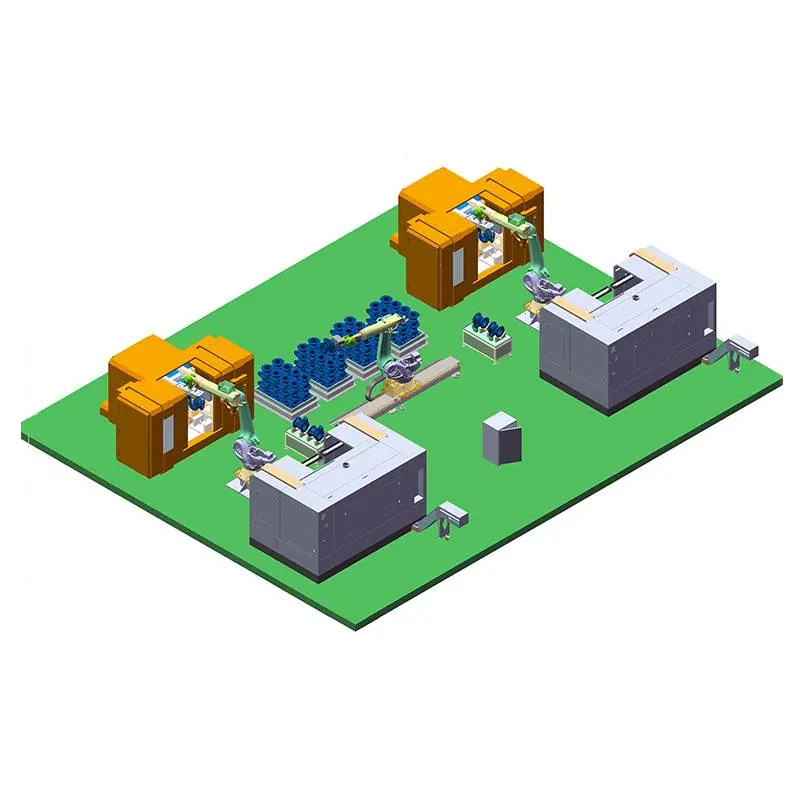

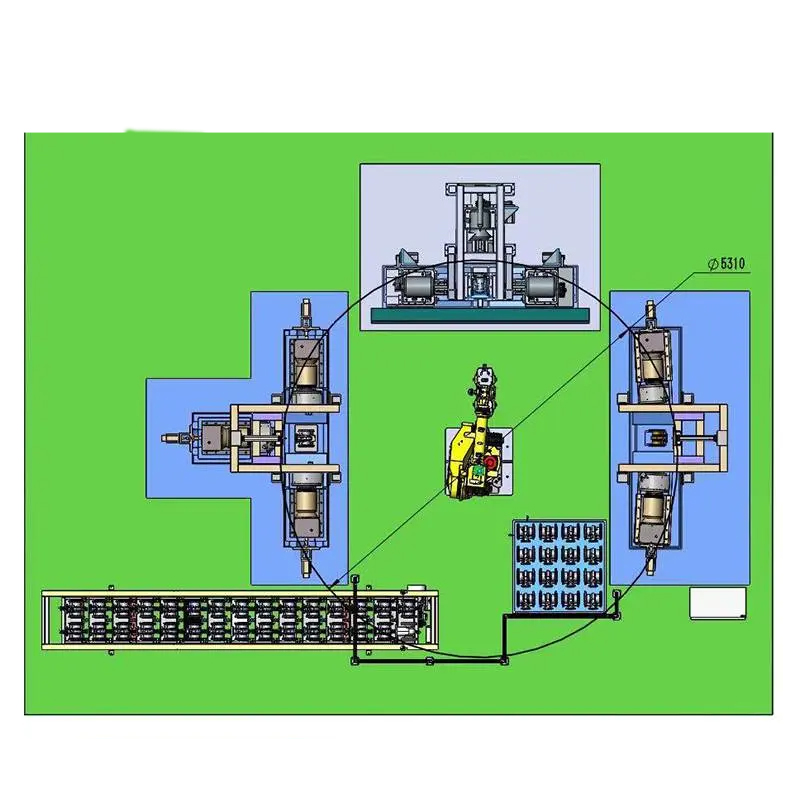

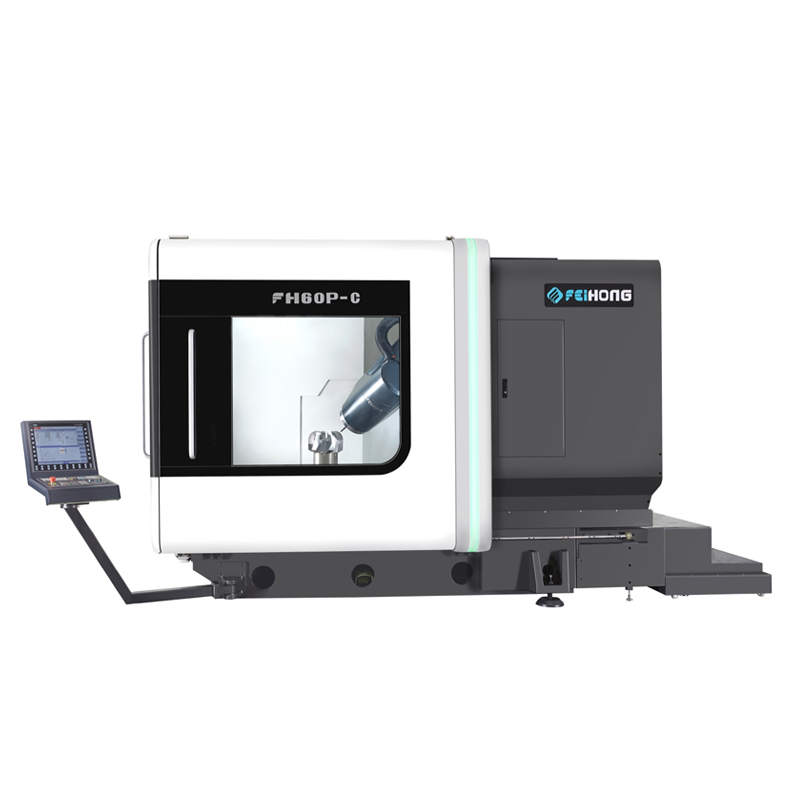

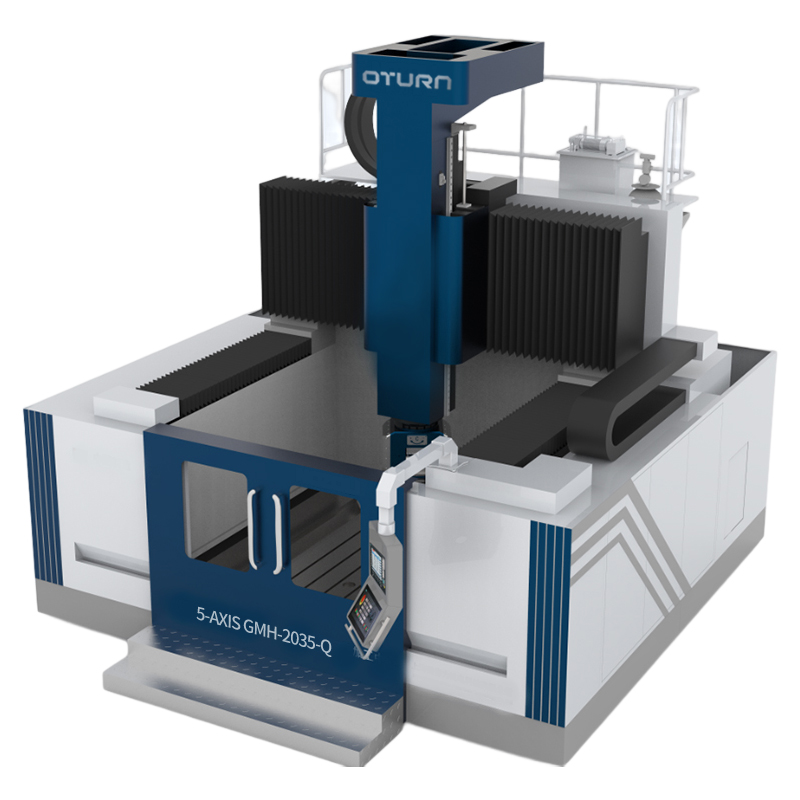

In the dynamic world of manufacturing, the lathe machine plays a crucial role, especially in valve applications. These machines are designed to ensure precision and accuracy, allowing for the intricate shaping of materials essential for high-quality valve production. From the initial concept to the final delivery, the process of creating lathe machines tailored for valve applications involves meticulous planning and expert execution. Understanding the unique requirements of valve manufacturing is vital. This includes considerations for material types, geometries, and production volumes. By leveraging advanced technology and engineering expertise, manufacturers can develop customized lathe machines that not only meet specifications but also enhance productivity and reduce cycle times. As global buyers seek efficient and reliable solutions, investing in state-of-the-art lathe machines can significantly improve operational efficiency and product quality. The journey from concept to delivery encompasses not only machine design but also rigorous testing and quality assurance processes. A robust supply chain ensures that every component of the lathe machine meets international standards, ultimately leading to successful valve production. By fostering strong partnerships and remaining committed to innovation, manufacturers are well-equipped to support the evolving needs of the global market, providing solutions that empower businesses to thrive in competitive landscapes.

Lathe Machine For Valve Application From Concept to Delivery

| Feature | Description | Specifications | Manufacturing Process | Lead Time |

|---|---|---|---|---|

| Precision Machining | High accuracy in valve components manufacturing | Tolerance of ±0.005 mm | CNC Lathe Turning | 4 weeks |

| Material Options | Variety of materials including brass, stainless steel, and aluminum | Material thickness: 5 mm - 200 mm | Material Selection and Testing | 2 weeks |

| Surface Treatment | Various surface finishes available for corrosion resistance | Plating, Coating, Anodizing | Post-Machining Processes | 3 weeks |

| Custom Design | Ability to create custom designs based on client requirements | CAD drawings required | Design Validation and Prototyping | 6 weeks |

| Quality Control | Thorough inspection throughout the machining process | Inspected to industry standards | Final Inspection and Testing | 1 week |

Related Products