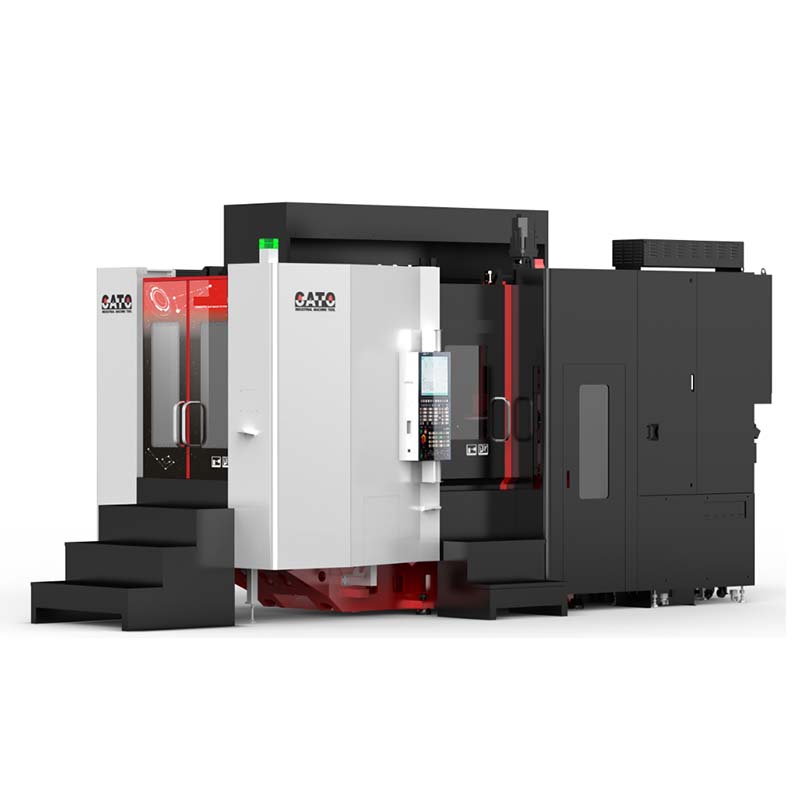

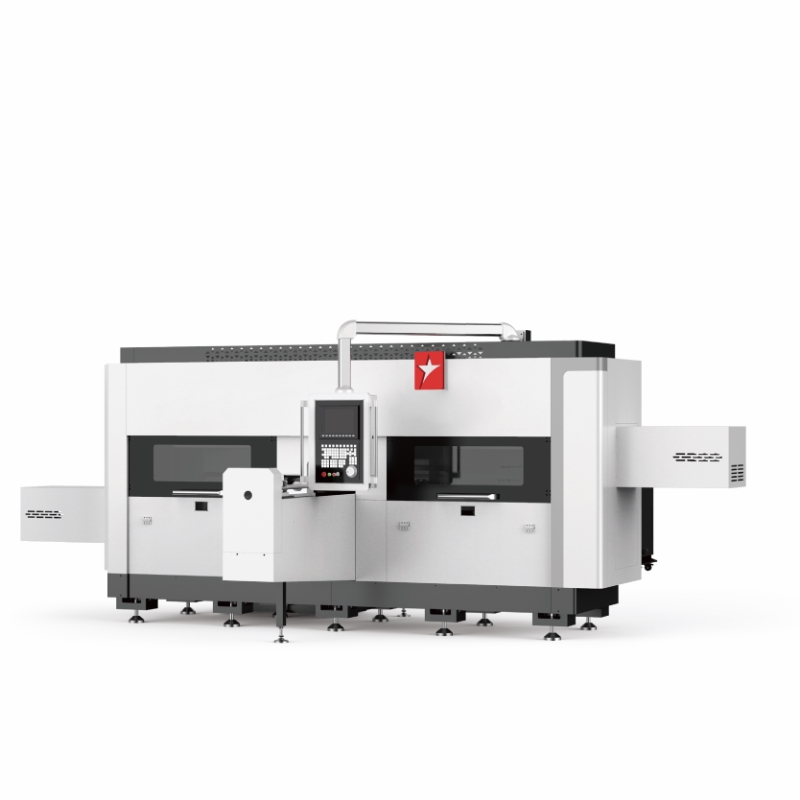

Top Drilling Milling Machines from China's Leading Manufacturer

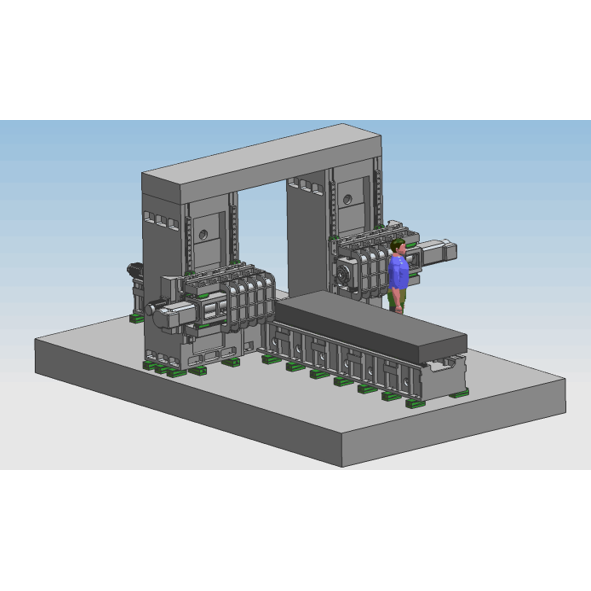

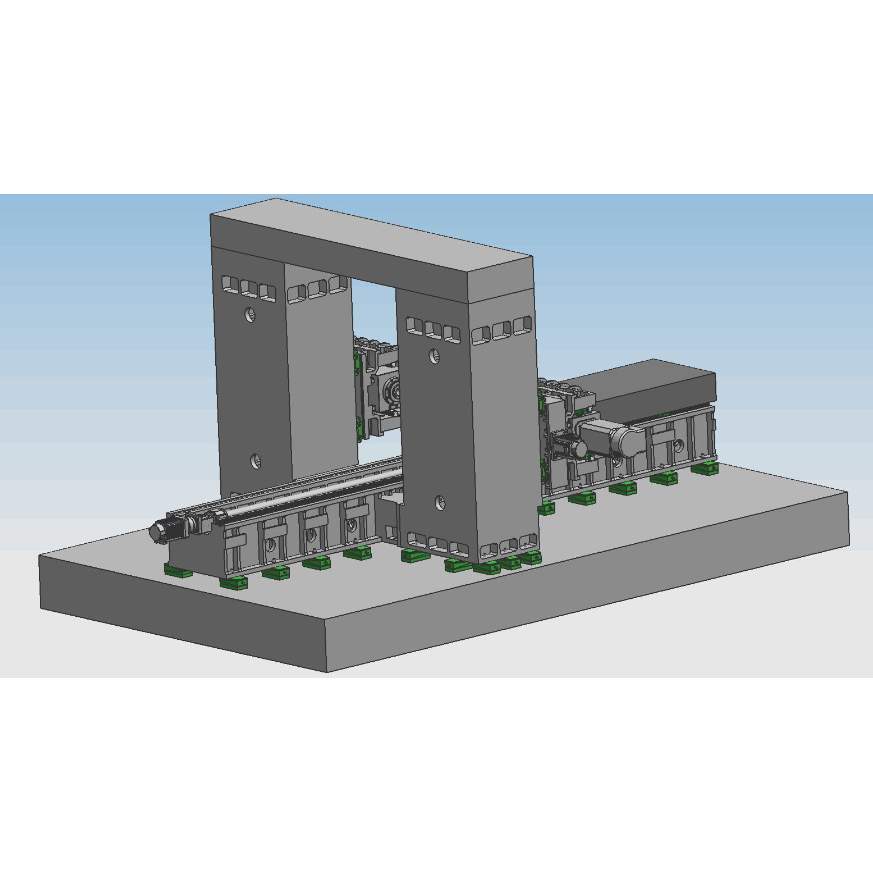

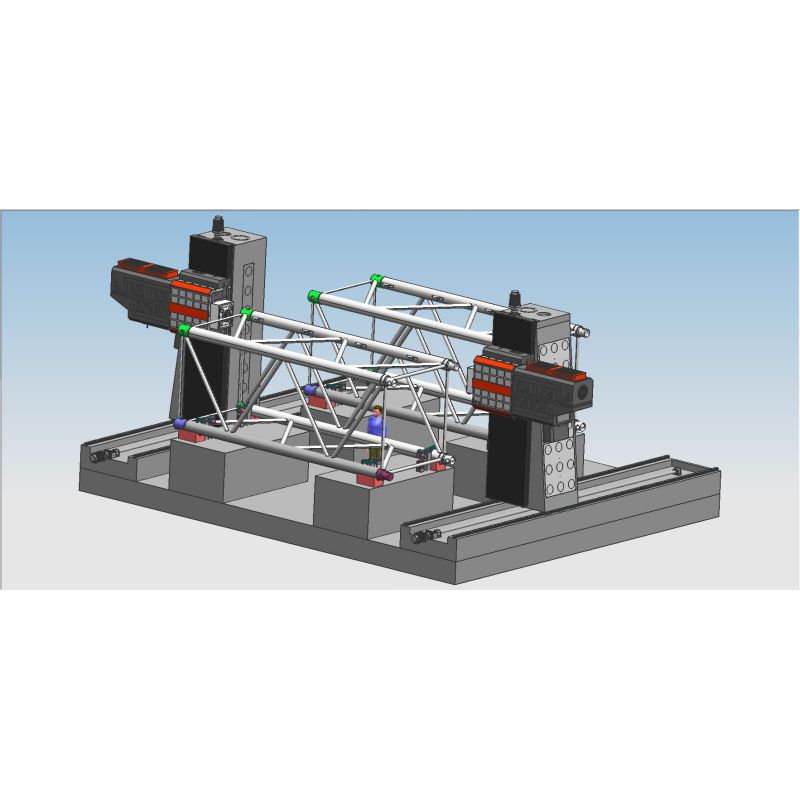

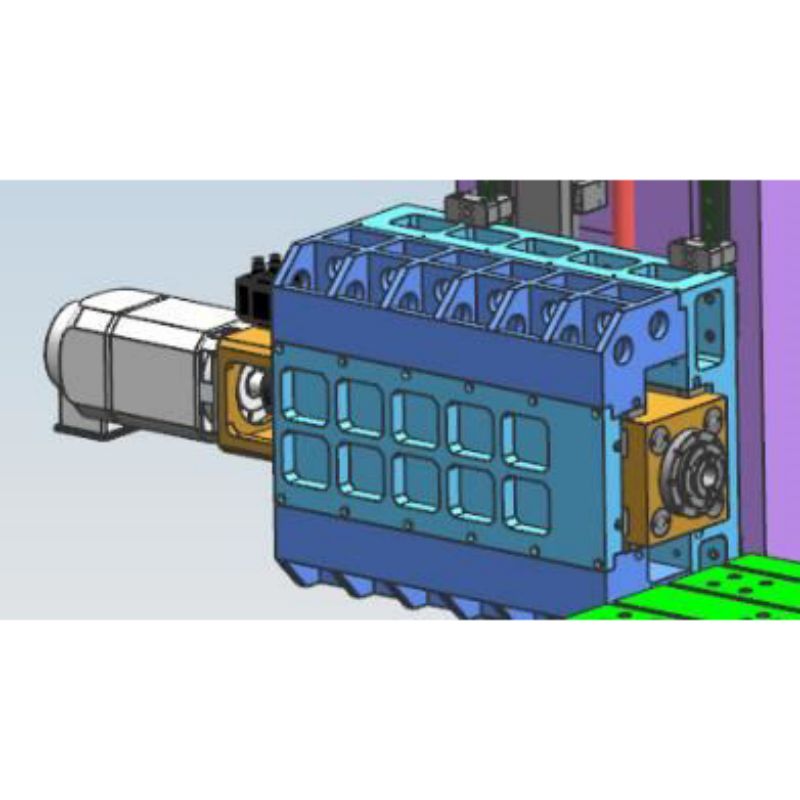

When it comes to precision and durability, I trust our Drilling Milling Machine to deliver exceptional performance for my business needs. Sourced directly from reputable manufacturers in China, this machine combines advanced technology with robust construction, ensuring it withstands the rigor of daily operations. Whether I’m drilling or milling, its versatility allows me to tackle various tasks with ease and accuracy. I appreciate the user-friendly interface that helps my team operate the machine efficiently. The reliability of our drilling milling machine minimizes downtime, which is crucial for maintaining productivity in any B2B setting. Plus, the competitive pricing we offer makes it a smart investment that enhances our overall output. If you’re aiming for precision and efficiency in your machining processes, I believe this is the perfect choice for your business. Let’s elevate your production capabilities together!

Drilling Milling Machine in 2025 Exceeds Industry Benchmarks

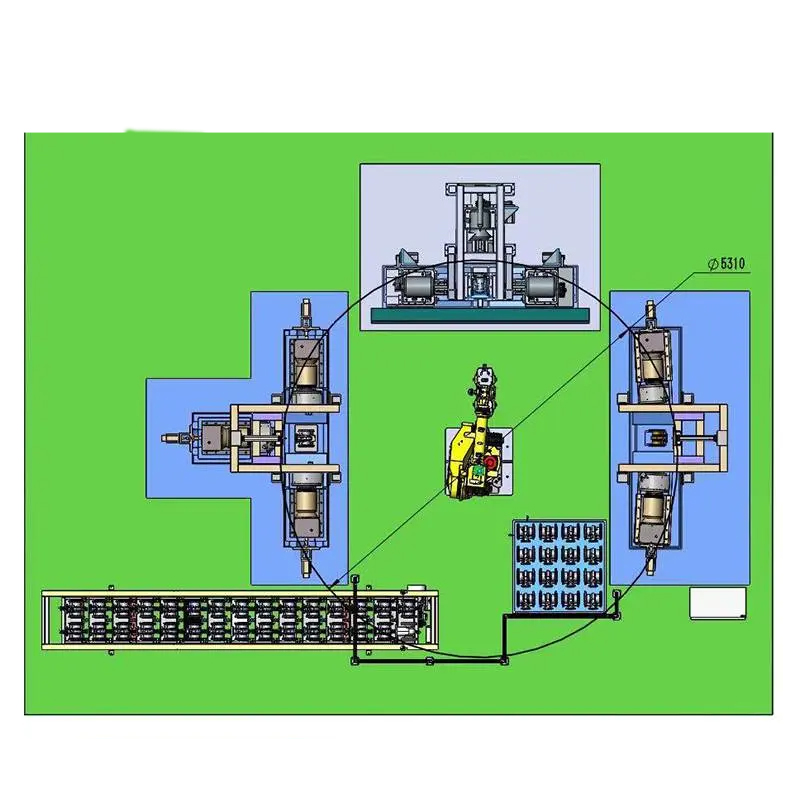

As we approach 2025, the demand for advanced drilling milling machines is set to surge, propelling these machines beyond traditional industry benchmarks. This evolution is primarily driven by the need for increased precision, efficiency, and versatility in manufacturing processes. Modern drilling milling machines integrate cutting-edge technologies, such as automation and smart manufacturing solutions, enabling manufacturers to enhance productivity and reduce operational costs. Globally, manufacturers are witnessing a shift towards machines that not only meet but exceed rigorous industry standards. The latest models come equipped with enhanced durability, user-friendly interfaces, and energy-efficient operations. These attributes are crucial for businesses striving to maintain competitiveness in a rapidly evolving market. As global procurement trends continue to lean towards quality and innovation, investing in next-generation drilling milling machines can lead to significant long-term benefits. Looking ahead, companies that prioritize the adoption of these advanced machines will be better positioned to achieve their production goals and meet customer demands effectively. The commitment to exceeding industry benchmarks ensures that manufacturers will not only keep pace with market needs but also set new standards for excellence in the machining industry.

Drilling Milling Machine Performance Metrics in 2025

| Metric | Value | Industry Benchmark | Percentage Above Benchmark |

|---|---|---|---|

| Max Spindle Speed (RPM) | 12000 | 10000 | 20% |

| Feed Rate (mm/min) | 800 | 600 | 33.33% |

| Accuracy (mm) | 0.02 | 0.05 | 60% |

| Power Consumption (kW) | 5 | 6.5 | -23.08% |

| Operational Noise Level (dB) | 75 | 80 | -6.25% |

Related Products