Top China Manufacturer of Double-Sided Processed Shaved Products

When it comes to double-sided processing and shaved products, I know how crucial it is for buyers to find reliable sources. As a manufacturer based in China, we specialize in delivering high-quality solutions that meet your precise specifications. Our commitment to excellence ensures that every piece we produce undergoes rigorous quality checks, making sure it fits perfectly into your production line. I understand that in the B2B market, timely delivery and consistent quality can make or break a deal. That’s why our processes are streamlined to cater to your urgent needs without compromising on quality. With advanced manufacturing techniques and innovative designs, we tailor our offerings to suit a variety of applications. Let’s collaborate to enhance your product lineup! If you're seeking a dependable partner who can deliver double-sided processed and shaved products, I’m here to ensure you receive the best service possible. Reach out, and let's create something great together!

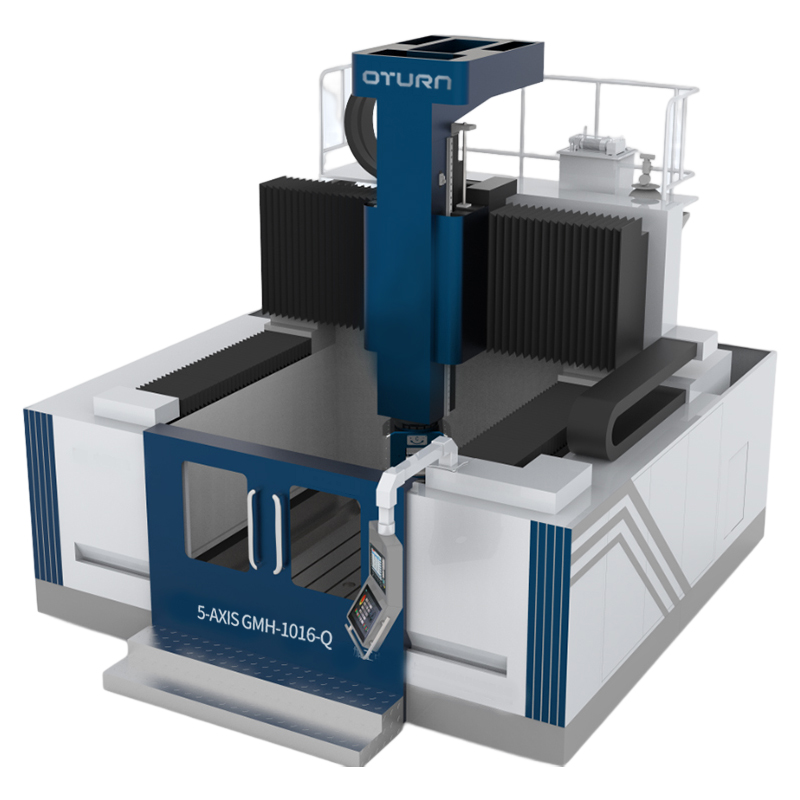

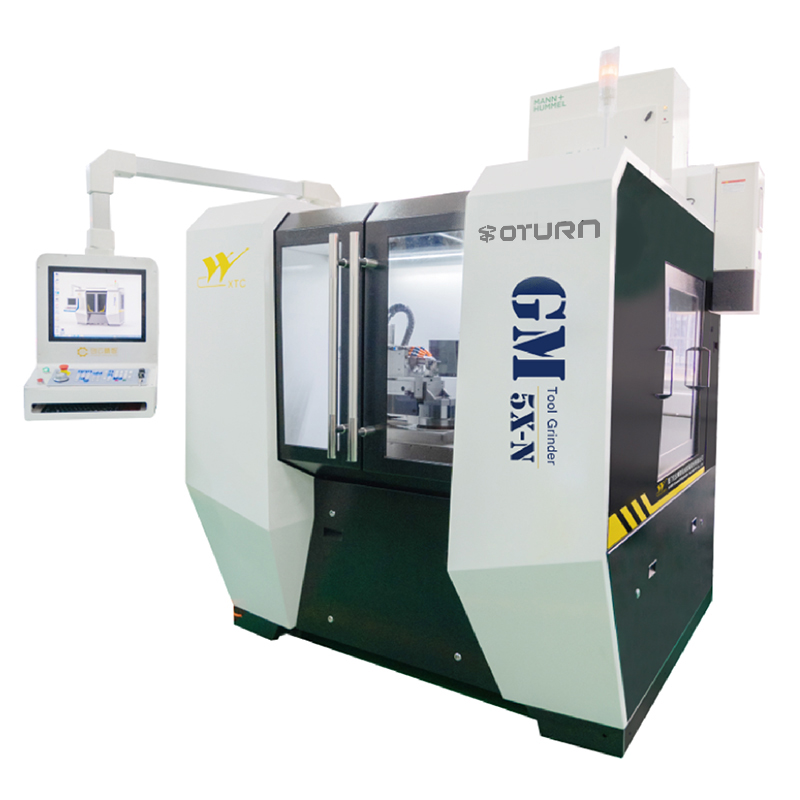

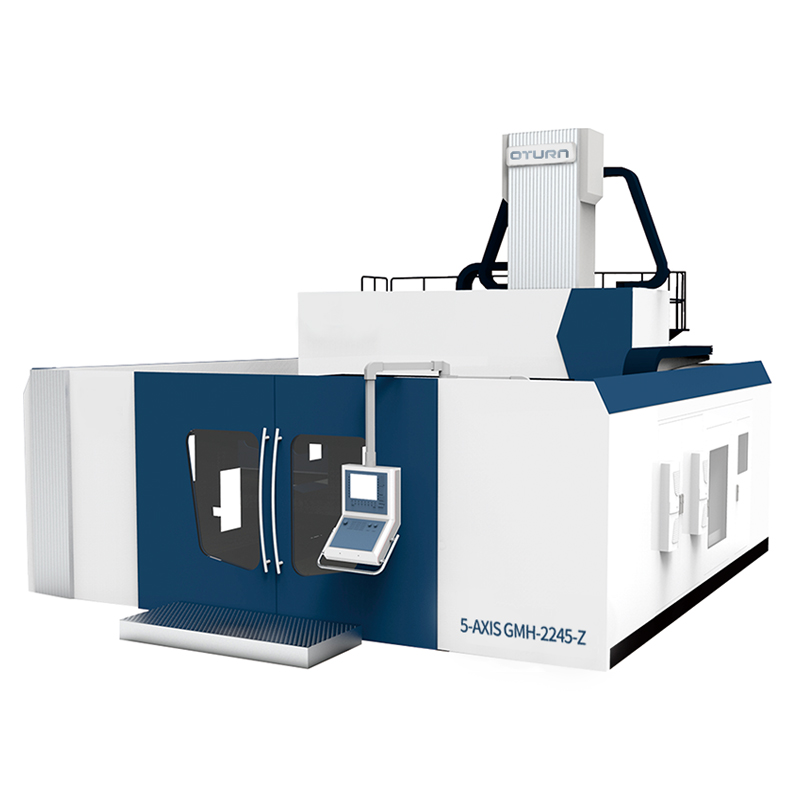

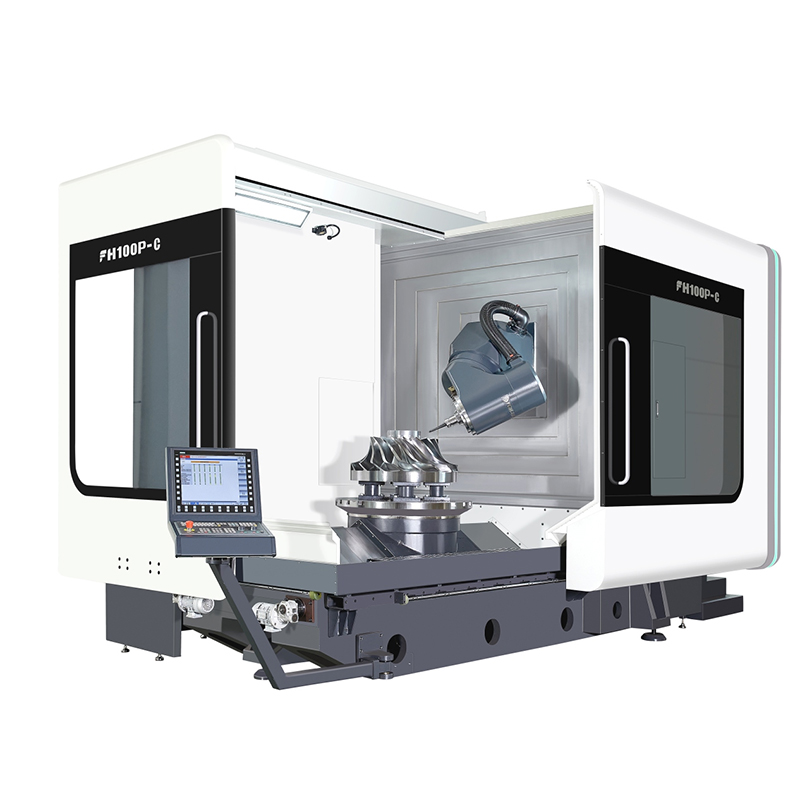

Double-sided processing,shaved Pioneers in the Field Custom Solutions,

In today’s competitive landscape, businesses demand innovative solutions that enhance efficiency and maximize performance. One such solution is double-sided processing, a method that revolutionizes how industries approach their manufacturing needs. This technology allows for more streamlined operations, reducing time and labor costs while increasing output quality. By employing double-sided processing, companies can create more intricate and precise components, meeting the high standards set by modern industries. Our tailored solutions in this field not only optimize production but also provide flexibility in design and application. Whether it’s customizing dimensions, materials, or specific functionalities, we work closely with clients to deliver products that cater to their unique requirements. This collaborative approach ensures that clients receive not just a product, but a comprehensive solution that enhances their operational workflows. As manufacturers seek to drive competitiveness and innovation, double-sided processing stands as a beacon of efficiency and precision. By partnering with leading experts in the field, global buyers can access customized solutions that significantly impact their operational capabilities. Embracing these advanced methodologies positions businesses to not only meet today’s demands but also prepare for the evolving future of manufacturing.

Double-sided processing, shaved Pioneers in the Field Custom Solutions

| Process Type | Material Type | Thickness (mm) | Surface Finish | Lead Time (days) |

|---|---|---|---|---|

| Double-sided Milling | Aluminum Alloy | 5 | Anodized | 15 |

| Laser Cutting | Stainless Steel | 2 | Polished | 10 |

| CNC Turning | Brass | 3 | Brushed | 12 |

| Surface Grinding | Mild Steel | 10 | Coated | 20 |

| Water Jet Cutting | Acrylic | 4 | Clear | 8 |

Related Products