CNC Tube Drilling Machine Manufacturer in China: Precision & Quality

When it comes to precision and efficiency in metalworking, our CNC tube drilling machine stands out in the industry. I’ve witnessed firsthand how this advanced machinery streamlines operations, making it ideal for manufacturers in China and beyond. With its cutting-edge technology, it drills accurately and quickly, significantly reducing production time. What sets our machines apart is their robust construction and user-friendly interface, allowing even those new to CNC machining to operate with ease. I’ve talked to clients who’ve transformed their production lines with our equipment, benefiting from reduced waste and enhanced accuracy. Choosing our CNC tube drilling machine means investing in quality and reliability, backed by our commitment to customer satisfaction. We understand the unique needs of manufacturers and are here to support you every step of the way. Let’s elevate your production capabilities together and drive your business forward in this competitive landscape.

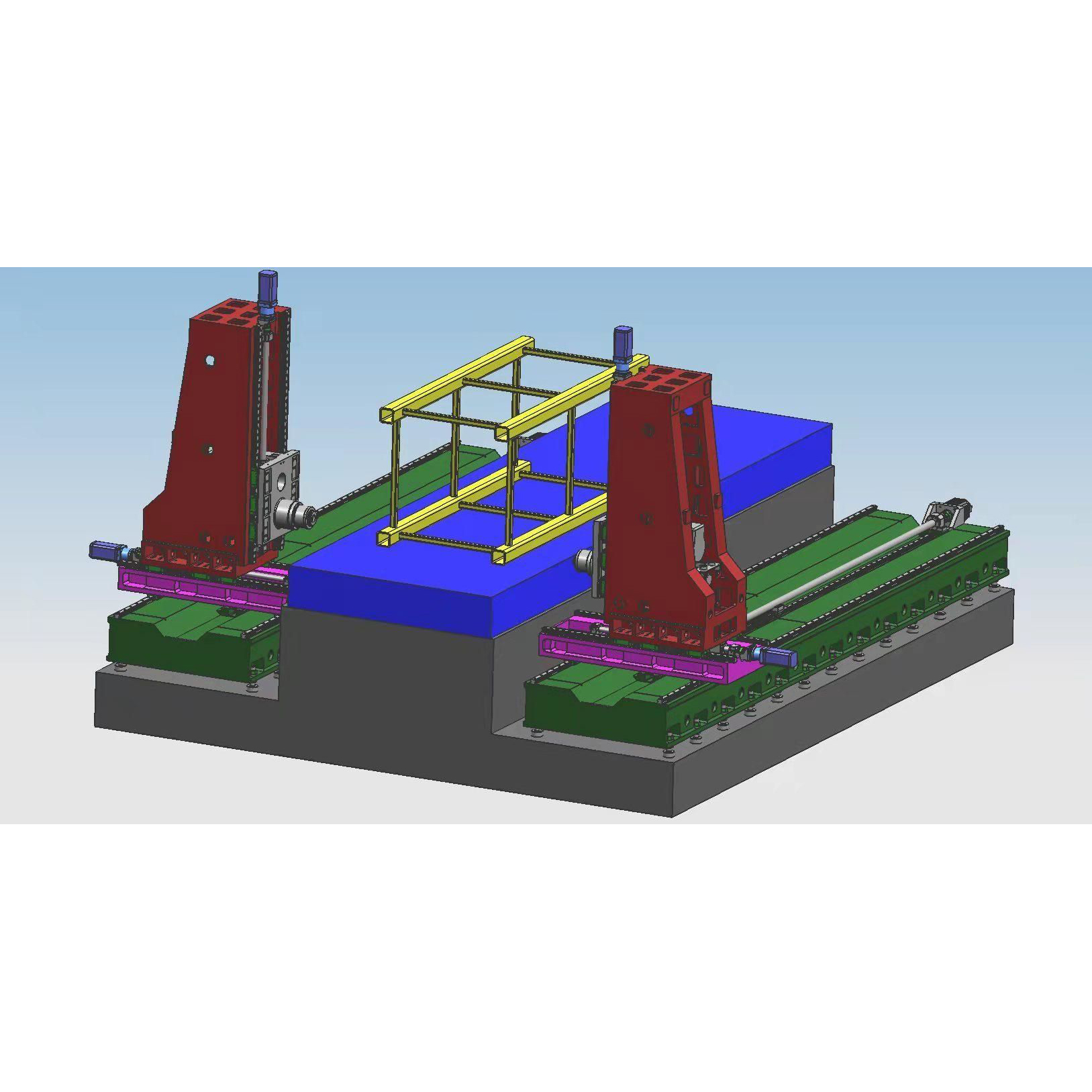

Cnc Tube Drilling Machine Factory Is The Best

In today's competitive manufacturing landscape, efficiency and precision are paramount. When it comes to tube processing, investing in high-quality CNC tube drilling machines can significantly enhance productivity and improve outcomes. The ideal machine not only streamlines the drilling process but also offers versatility for various applications, ensuring that manufacturers can meet diverse production needs. A leading factory in CNC tube drilling machine manufacturing provides innovative solutions that cater to the specific requirements of global buyers. These machines boast advanced technology, featuring automated systems that minimize manual input and reduce errors, leading to faster turnaround times and superior product quality. Additionally, comprehensive support and maintenance services ensure that operations remain smooth and downtime is minimized. Choosing the right CNC tube drilling machine factory is crucial for businesses looking to expand their capabilities. By partnering with a reputed manufacturer, customers gain access to cutting-edge technology, exceptional engineering expertise, and a commitment to delivering durable, high-performance machines that adapt to evolving industry demands. Embracing such advancements not only positions companies for success but also helps them stay ahead in a rapidly changing market.

Cnc Tube Drilling Machine Factory Is The Best

| Model | Type | Drilling Depth (mm) | Max Tube Diameter (mm) | Power (kW) | Speed (RPM) |

|---|---|---|---|---|---|

| Model A | Vertical | 100 | 50 | 5 | 1500 |

| Model B | Horizontal | 200 | 60 | 7.5 | 1200 |

| Model C | CNC | 150 | 75 | 10 | 1800 |

| Model D | Portable | 80 | 40 | 3 | 2000 |

Related Products