Cnc Pipe Threading Lathe Machine Manufacturer in China - Quality Assured

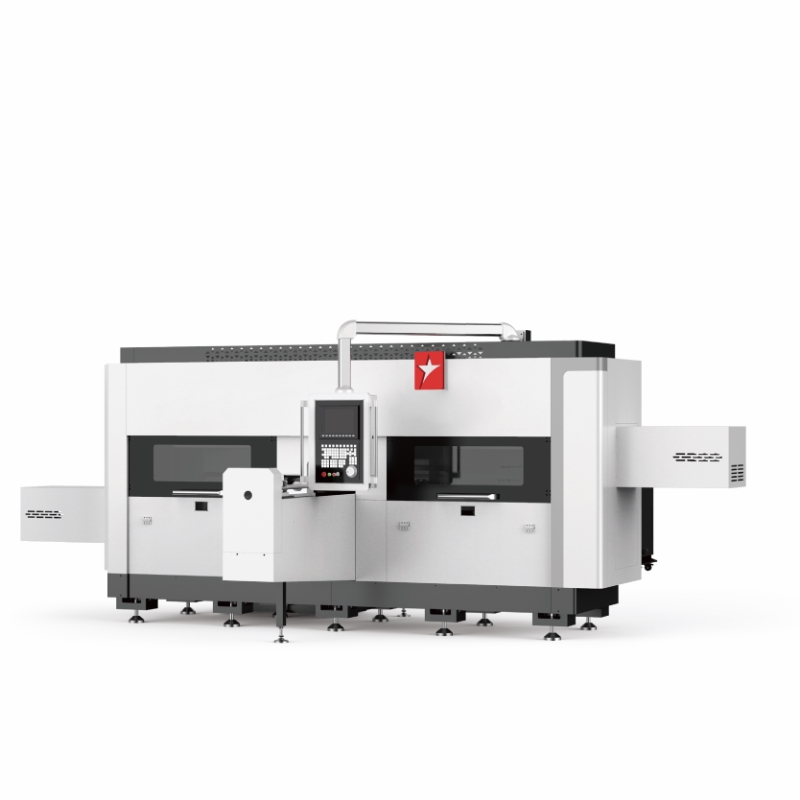

When I'm in the market for a reliable Cnc Pipe Threading Lathe Machine, I always prioritize quality and efficiency. Our machines, manufactured right here in China, are designed specifically to meet the demands of modern manufacturing. I appreciate how these lathes can effortlessly handle various pipe sizes, providing precision threading that saves time and reduces waste. The robust build ensures long-lasting performance, making it an ideal investment for my business. Plus, the user-friendly interface allows for easy operation, which is crucial for my team. I find the attention to detail in the engineering truly impressive—it's a product built with industry needs in mind. Partnering with a trusted manufacturer means I can count on consistent support and service. If you’re serious about enhancing your production capabilities, consider this Cnc Pipe Threading Lathe Machine. It’s a game-changer that fits perfectly into any workshop seeking efficiency and reliability.

Cnc Pipe Threading Lathe Machine Leads the Global Market From Concept to Delivery

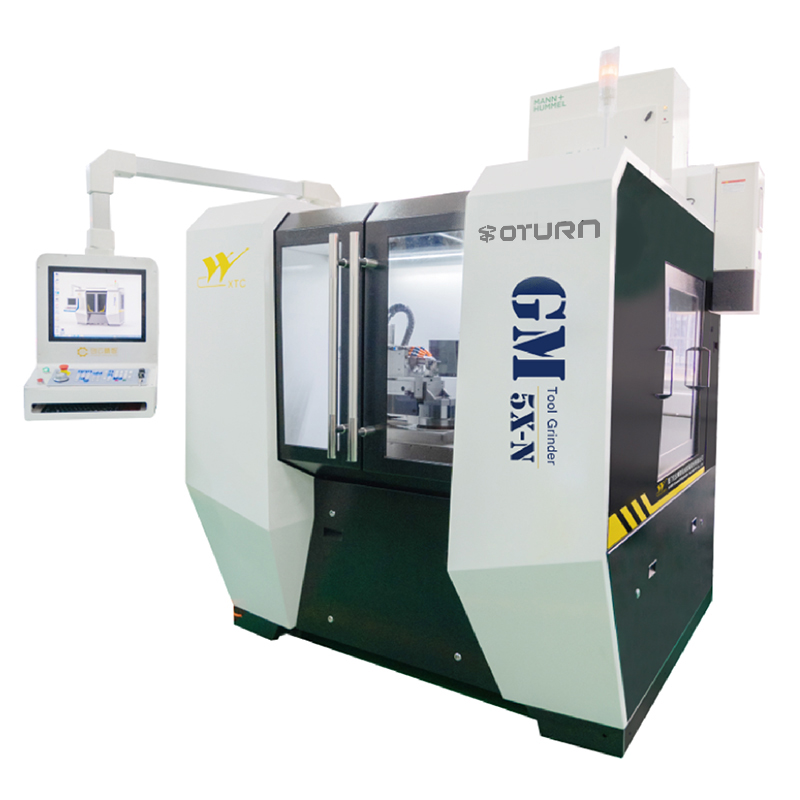

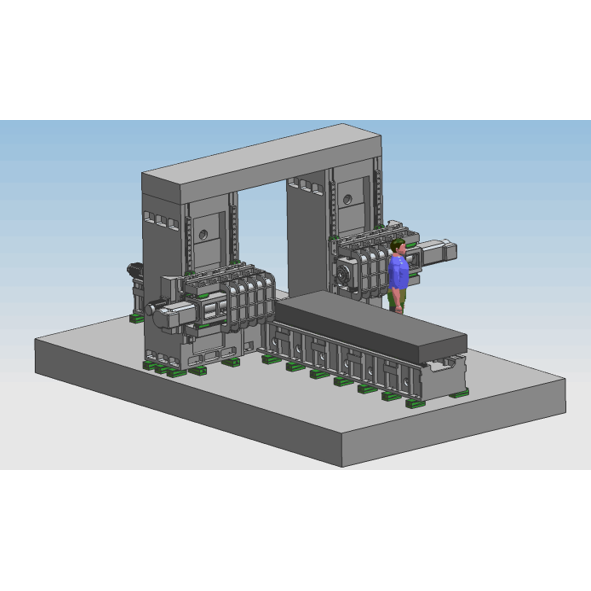

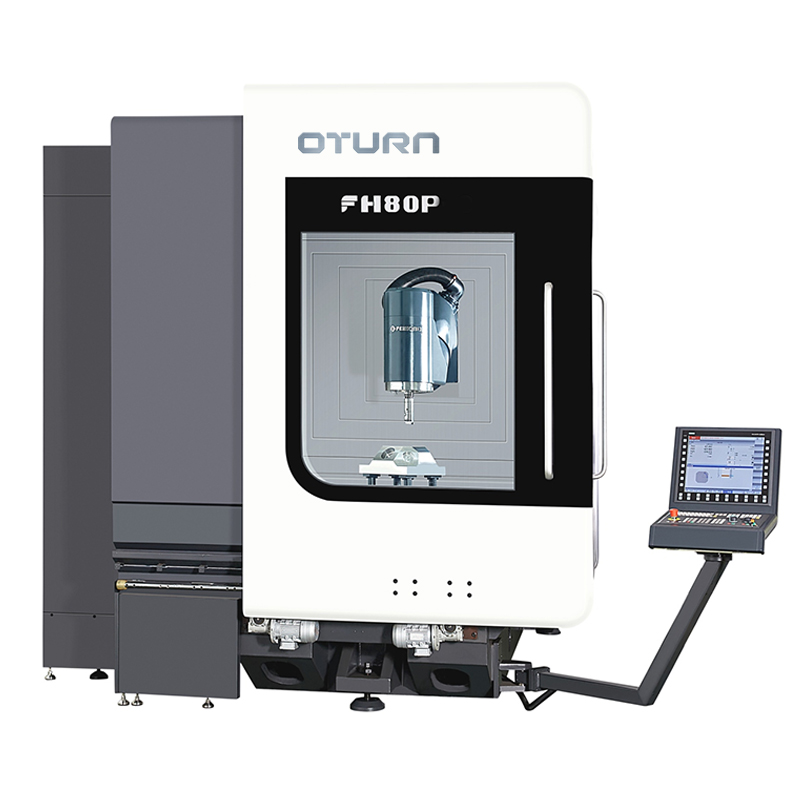

In today's highly competitive manufacturing landscape, the demand for precision and efficiency is at an all-time high. Cnc pipe threading lathe machines have emerged as essential tools in various industries, revolutionizing the way pipe threading is approached. These machines provide unmatched accuracy and speed, enabling manufacturers to streamline their operations and enhance productivity. Whether it's for oil and gas, construction, or automotive applications, the ability to deliver high-quality threaded pipes is crucial for meeting global standards. As industries evolve, the ability to innovate from concept to delivery becomes paramount. Advanced CNC technology integrates intelligent automation, precision engineering, and user-friendly interfaces, allowing operators to achieve complex threading tasks with minimal effort. This not only reduces the likelihood of errors but also accelerates production times, catering to the growing needs of global procurement. In an era where time is money, leveraging cutting-edge machinery can be a game-changer for businesses looking to stay ahead. For global buyers seeking reliable solutions, investing in a CNC pipe threading lathe machine represents a strategic decision that can significantly impact their operations. With features such as programmable controls and high durability, these machines not only promise longevity but also adaptability to various threading specifications. As the market continues to expand, access to top-notch machinery can provide companies with a competitive edge, ensuring they meet customer demands efficiently and effectively.

Cnc Pipe Threading Lathe Machine Leads the Global Market From Concept to Delivery

| Specification | Details |

|---|---|

| Machine Type | CNC Pipe Threading Lathe |

| Available Sizes | 1/2" to 6" Pipe Diameter |

| Functionality | Threading, Cutting, Boring |

| Control System | User-friendly CNC Interface |

| Power Consumption | 5 kW |

| Weight | 2000 kg |

| Delivery Time | 6-8 Weeks |

| Industry Applications | Oil & Gas, Plumbing, Construction |

Related Products