Top CNC Milling Center Manufacturers in China for Precision Machining

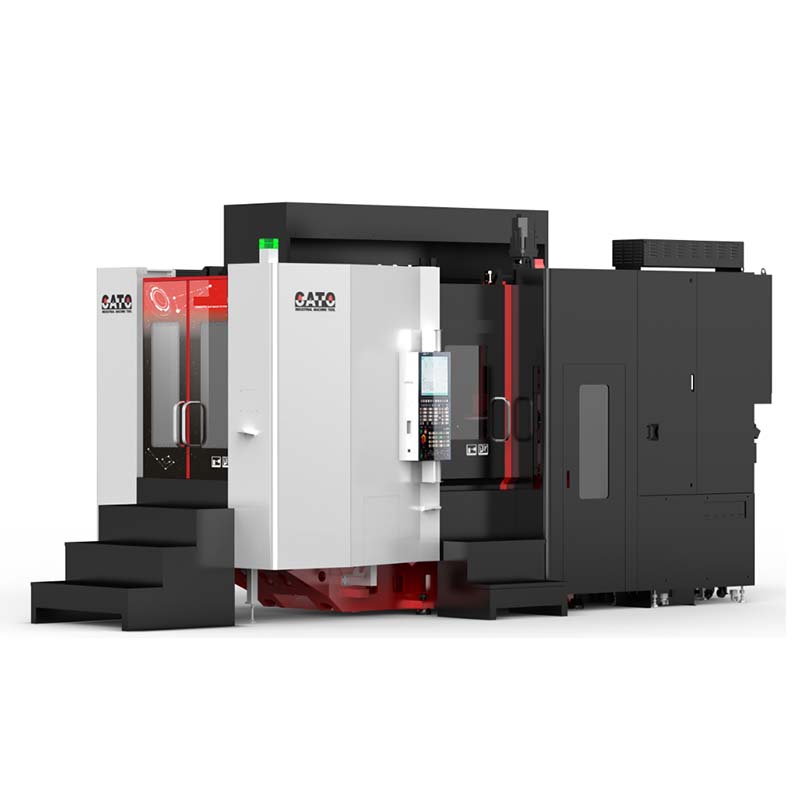

When it comes to precision and efficiency in machining, I can't recommend a CNC milling center from China enough. These machines are designed to handle a variety of complex tasks with incredible accuracy, making them essential for any manufacturer looking to enhance their production capabilities. With robust construction and advanced technology, these CNC milling centers can streamline your manufacturing processes, ensuring high-quality output while reducing waste. Utilizing one of these centers means investing in reliable performance that can keep up with your demanding production schedules. It’s not just about the machinery, but also the excellent customer support and services that come from experienced Chinese manufacturers. I’ve personally seen how these machines can transform operations, and I'm confident they will exceed your expectations in precision engineering. If you want to elevate your manufacturing game, this is the solution you need!

Cnc Milling Center Ahead of the Curve Winning in 2025

As we look toward 2025, the landscape of CNC milling centers is set to evolve dramatically, driven by advancements in technology and shifting market demands. The key to thriving in this competitive arena lies in staying ahead of the curve. Manufacturers that leverage cutting-edge automation, enhance precision, and integrate smart technologies will not only improve operational efficiency but also meet the rising expectations of global buyers. One of the crucial trends shaping the future of CNC milling is the adoption of intelligent manufacturing solutions. These solutions, which involve the Internet of Things (IoT) and data analytics, enable real-time monitoring and optimization of machining processes. Companies that embrace these technologies will find themselves equipped to deliver high-quality, customized products with shorter lead times, addressing the growing demand for flexibility in production. Additionally, sustainability initiatives will play a pivotal role, as environmentally conscious manufacturing practices become increasingly important for procurement decisions. To win in 2025, collaboration and innovation will be essential. Engaging with suppliers and customers to understand their evolving needs will form the backbone of agile, responsive operations. By investing in training and development for the workforce, organizations can ensure they have a skilled team capable of utilizing advanced CNC technologies effectively. Together, these strategies will not only enhance competitiveness but also foster long-term relationships in a dynamic global market.

Cnc Milling Center Ahead of the Curve Winning in 2025

| Dimension | Measurement | Material | Technology | Market Share (%) | Projected Growth Rate (%) |

|---|---|---|---|---|---|

| X-Axis Travel | 800 mm | Aluminum | CNC | 25 | 15 |

| Y-Axis Travel | 500 mm | Steel | Milling | 30 | 10 |

| Z-Axis Travel | 400 mm | Plastic | Laser | 20 | 12 |

| Max RPM | 12000 | Titanium | 3D Printing | 18 | 8 |

| Tool Change Time | 1.5 s | Composite | EDM | 22 | 14 |

Related Products