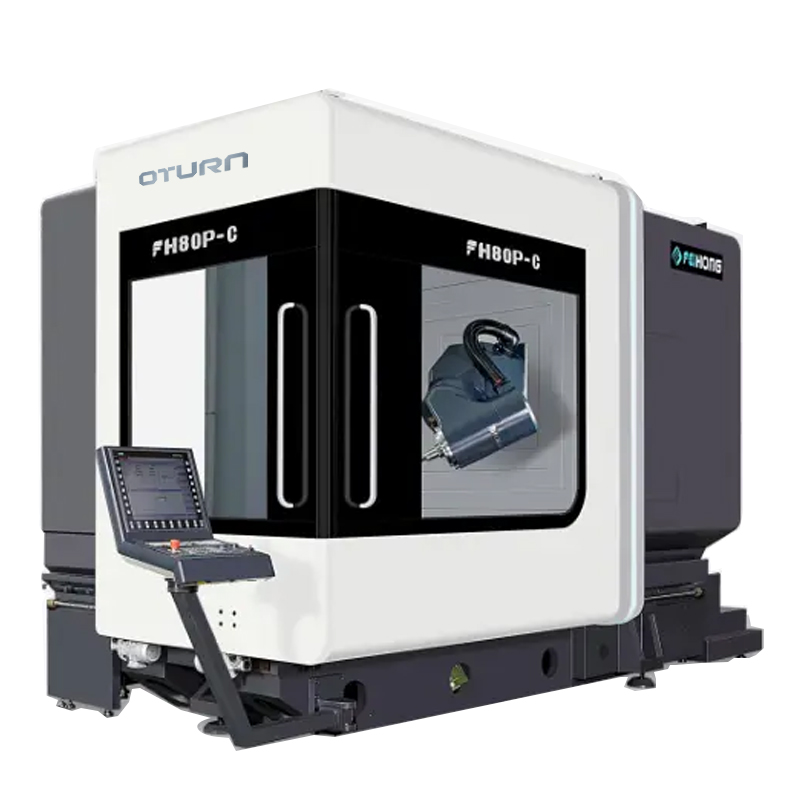

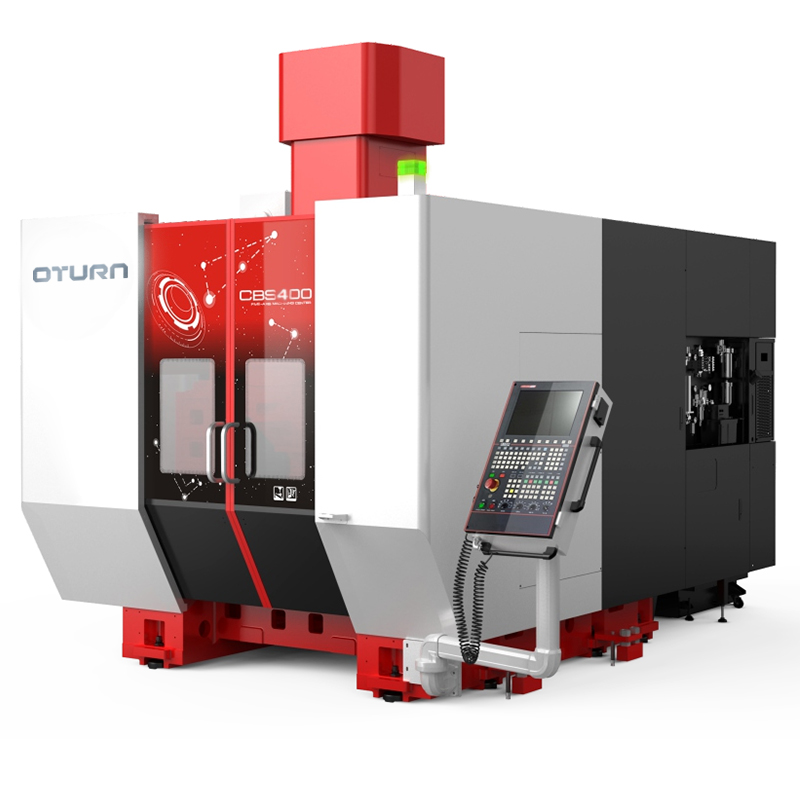

CNC Heavy Duty Drilling and Milling Machine Manufacturer in China

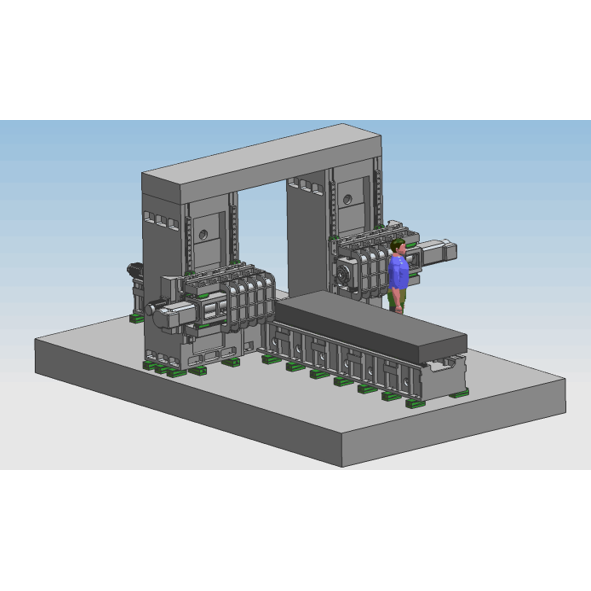

When it comes to precision engineering, my CNC Heavy Duty Drilling and Milling Machine stands out. Designed for those who demand reliability and performance, this machine is perfect for tackling even the toughest materials. I take pride in the fact that it’s manufactured in China, ensuring top-notch build quality at competitive prices. With advanced features that enhance efficiency and accuracy, I know this machine can optimize your production processes. Whether you’re a small workshop or a large manufacturing plant, it adapts to meet your needs. My commitment to customer satisfaction means you’ll also receive excellent support and service, making your purchasing experience seamless. Investing in my CNC Heavy Duty Drilling and Milling Machine means investing in the future of your business, combining durability with high precision. Let’s elevate your machining capabilities together and drive your productivity to new heights.

CNC Heavy Duty Drilling and Milling Machine Guarantees Peak Performance Where Service Meets Innovation

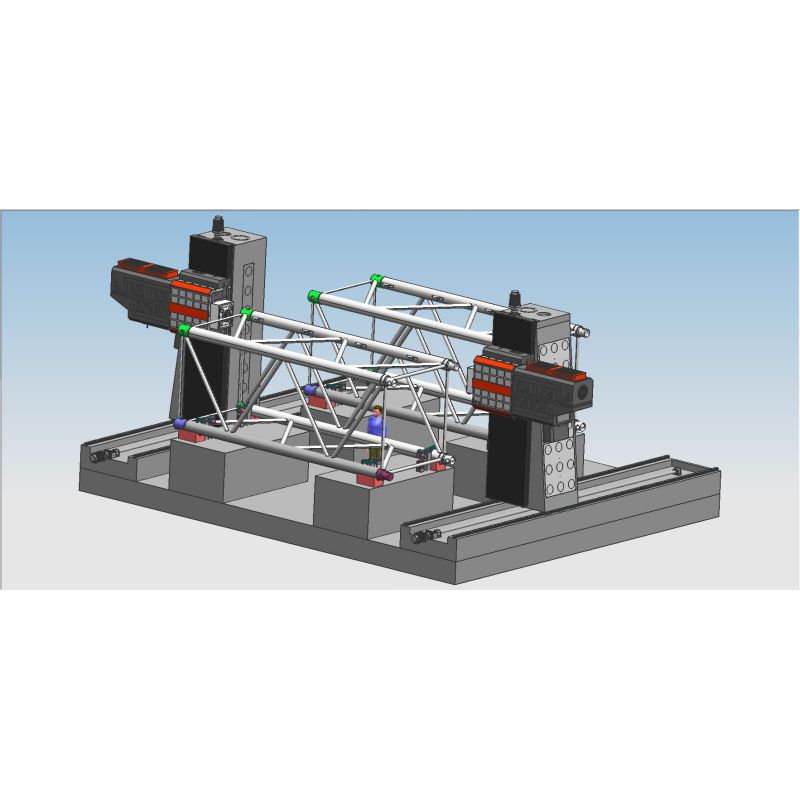

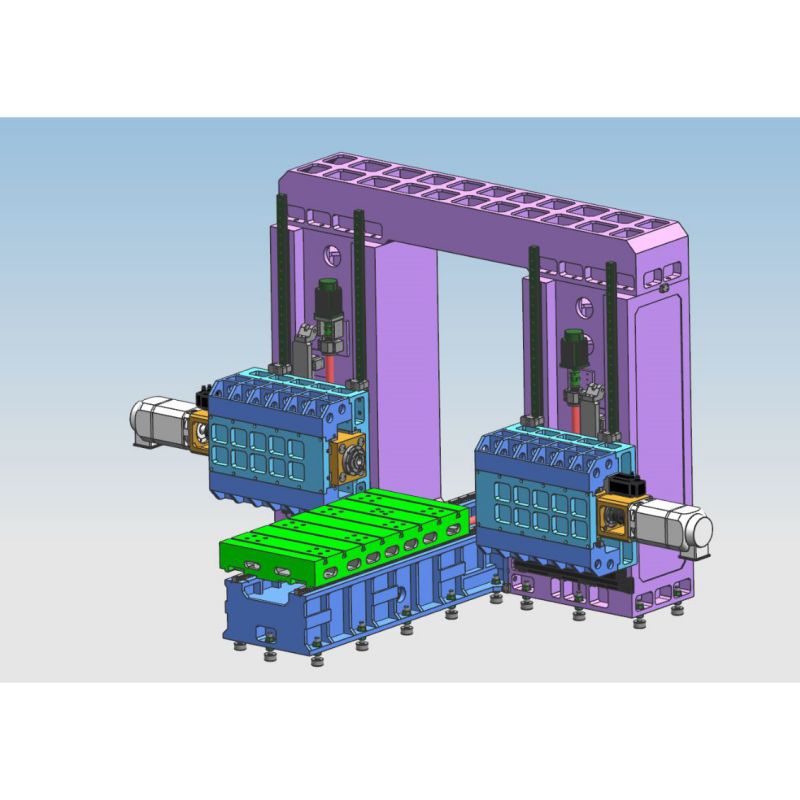

In the fast-paced world of manufacturing, the demand for precision and efficiency has never been higher. The CNC Heavy Duty Drilling and Milling Machine stands out as a powerhouse in this sector, engineered to deliver peak performance for various applications. This innovative machine seamlessly combines advanced technology with robust design, enabling manufacturers to tackle even the most challenging tasks. With the ability to produce intricate components with unmatched accuracy, it sets a new standard in the industry, making it an indispensable tool for businesses aiming to enhance their operational capabilities. What truly distinguishes this machine is its commitment to service and innovation. Each unit is designed with user-friendly features that streamline operations, while also offering extensive customization options to meet unique project requirements. Whether you're working with tough materials or intricate designs, this drilling and milling machine provides the reliability and precision that global procurement specialists seek. By investing in this technology, businesses not only improve their productivity but also position themselves competitively in the ever-evolving market landscape. In conclusion, the CNC Heavy Duty Drilling and Milling Machine embodies a perfect blend of service and innovation, ensuring that manufacturers can meet the highest standards of performance. As industries grow increasingly demanding, this equipment not only fulfills operational needs but also drives growth through enhanced productivity and efficiency. Embracing such advanced technology is a strategic move for businesses looking to secure their place as leaders in the global marketplace.

CNC Heavy Duty Drilling and Milling Machine Guarantees Peak Performance Where Service Meets Innovation

| Feature | Description | Application | Material Compatibility |

|---|---|---|---|

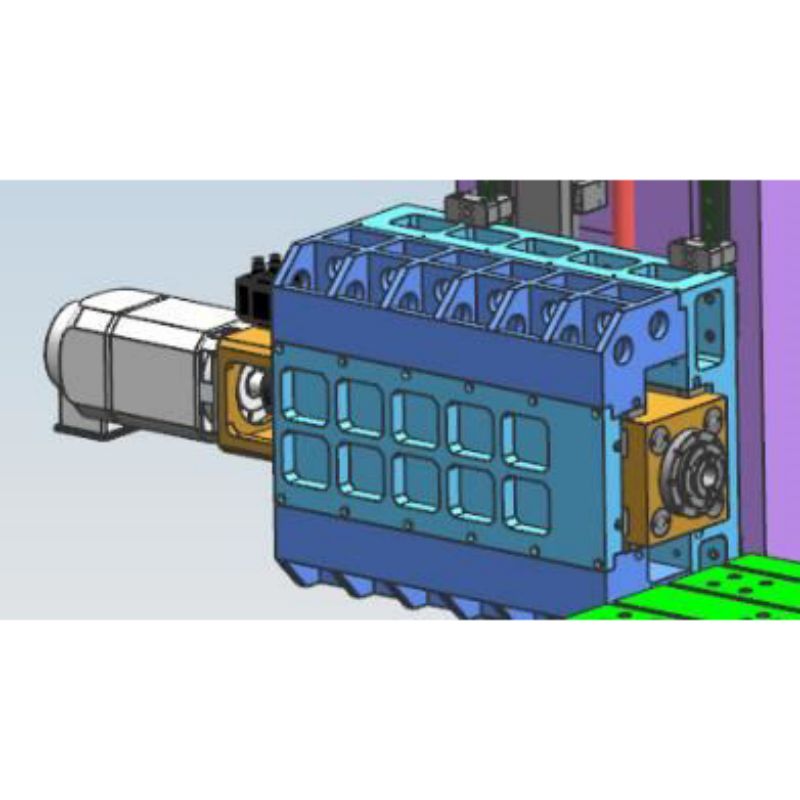

| Powerful Spindle | High-speed spindle ensures efficient drilling and milling. | Industrial manufacturing, Aerospace, Automotive | Aluminum, Steel, Titanium |

| Robust Construction | Heavy-duty frame for stability during operation. | Construction, Heavy machinery, Tool making | Cast Iron, Stainless Steel |

| Advanced Tooling | Integrates a variety of tooling options for versatility. | Custom parts manufacturing, Prototyping | Composite materials, Plastics |

| User-friendly Interface | Intuitive controls for easy operation and setup. | Education, Hobbyist projects | Wood, Soft metals |

| High Precision | Achieves tight tolerances for intricate features. | Medical devices, Aerospace components | Alloys, Engineered plastics |

Related Products