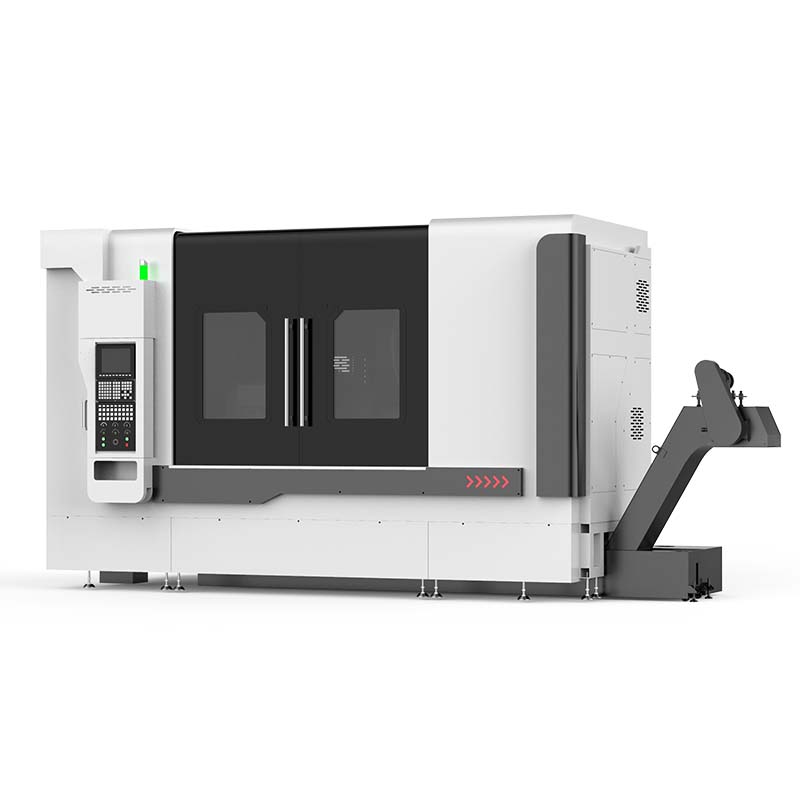

Top China Manufacturer of Valve Turning Lathes for Precision Machining

As a seasoned professional in the valve manufacturing industry, I understand the importance of precision and reliability in your production line. Our Valve Turning Lathe is expertly designed to enhance your efficiency and quality when it comes to valve machining. Sourced directly from trusted manufacturers in China, this lathe offers superior accuracy and durability to meet the demanding needs of your business. I really appreciate the seamless operation and innovative features that our Valve Turning Lathe brings to the table. It's built to handle various valve sizes, ensuring you always get the best results. Plus, with reliable support and competitive pricing from our China-based manufacturer, investing in this equipment can be a game-changer for your production process. If you’re ready to take your operations to the next level, this lathe is the solution you’ve been searching for. Let’s simplify your valve production together!

Valve Turning Lathe Pioneers in the Field Supplies the World\u2019s Top Brands

In the realm of precision engineering, valve turning lathes represent a crucial advancement for manufacturers looking to optimize their production capabilities. These machines are designed to deliver unparalleled accuracy, ensuring that each valve component meets the stringent requirements of various industries, including oil and gas, automotive, and aerospace. As global demand for high-quality components continues to rise, innovative lathe technology has become essential for companies aiming to maintain competitive advantages and enhance operational efficiency. Leading the charge in this field are manufacturers who prioritize state-of-the-art design and functionality. By incorporating advanced features such as CNC control, automated tooling, and real-time monitoring systems, these lathes streamline the valve production process, reducing waste and minimizing downtime. Furthermore, their adaptability allows for customization to suit specific client needs, making them a favored choice among the world’s top brands. Companies that invest in modern valve turning lathes not only improve their production quality but also significantly shorten lead times, which is crucial in a fast-paced global marketplace. As buyers seek reliable partners for their manufacturing needs, the focus is shifting towards suppliers who can offer comprehensive solutions backed by technological innovation and superior service. Collaborating with industry pioneers in valve turning lathe production allows businesses to leverage cutting-edge technology, ensuring they stay ahead of trends and meet the evolving demands of their customers. The future of manufacturing lies in these advanced machines, which are set to redefine standards and push the boundaries of what's possible in precision engineering.

Valve Turning Lathe Pioneers in the Field Supplies the World’s Top Brands

| Dimension | Specification | Material | Application Area | Technology Used |

|---|---|---|---|---|

| 500mm x 1000mm | Precision Turning | Alloy Steel | Industrial Valves | CNC Machining |

| 600mm x 1200mm | Heavy Duty Turning | Stainless Steel | Oil & Gas | Hydraulic Technology |

| 300mm x 800mm | Compact Turning | Carbon Steel | Automotive | Robotic Automation |

| 400mm x 1500mm | High Precision | Bronze | Marine Applications | Laser Technology |

Related Products