News

-

Don’t forget to add lubricating grease to the power head

Common types of power heads in CNC machine tools include drilling power heads, tapping power heads, and boring power heads. Regardless of the type, the structure is roughly the same, and the interior is rotated by the combination of the main shaft and the bearing. The bearing needs to be fully lu...Read more -

Introduction to the basic layout of CNC slant type lathes in 2022

CNC slant type lathe is an automatic machine tool with high precision and high efficiency. Equipped with a multi-station turret or a power turret, the machine tool has a wide range of processing performance, which can process linear cylinders, oblique cylinders, arcs and various threads, grooves,...Read more -

What should I pay attention to when using horizontal lathes in Southeast Asia?

Horizontal lathes can process various types of workpieces such as shafts, discs, and rings. Reaming, tapping and knurling, etc. Horizontal lathes are the most widely used type of lathes, accounting for about 65% of the total number of lathes. They are called horizontal lathes because their spindl...Read more -

What skills need to be mastered in the application of CNC drill machines in Russia?

When clamping the CNC drilling machine workpiece, it should be clamped firmly to prevent the workpiece from flying out and causing an accident. After the clamping is completed, pay attention to take out the chuck wrench and other adjustment tools, so as to avoid the accident caused by the spindle...Read more -

How to solve the problem of cutting vibration in India?

In CNC milling, vibration may be generated due to the limitations of cutting tools, tool holders, machine tools, workpieces or fixtures, which will have certain adverse effects on machining accuracy, surface quality, and machining efficiency. To reduce cutting vibration, related factors need to b...Read more -

What are the absolute processing advantages of CNC drilling machine in Turkey

Through the control of the computer, the CNC drill machine performs automatic positioning according to the program and automatically adjusts to the best feed amount according to different hole diameters. This processing mode of CNC drill machine is widely used in all walks of life, and its obviou...Read more -

Basic operation steps of BOSM CNC machine tools

Everyone has a corresponding understanding of CNC machine tools, so do you know the general operation steps of BOSM CNC machine tools? Don’t worry, here’s a brief introduction for everyone. 1. Editing and input of workpiece programs Before processing, the processing technology of the ...Read more -

What are the requirements of the CNC drilling machine for the environment in South America?

High speed CNC drilling and milling machine is a relatively new type of machine. It is more efficient than traditional radial drills, has lower cost output and simpler operation than ordinary milling machines or machining centers, so there is a great demand in the market. Especially for tube shee...Read more -

Will conventional lathe machine be eliminated in Russia?

With the popularity of CNC machining,more and more automation equipment is emerging in the market. Nowadays, many conventional machine tools in factories are replaced by CNC machine tools.Many people speculate that conventional lathes will be completely eliminated in the near future. Is this tr...Read more -

What is the difference between CNC vertical lathes and CNC milling machines?

CNC vertical lathes and CNC milling machines are common in modern machining, but many people do not know them enough, so what is the difference between CNC vertical lathes and CNC milling machines? The editor will introduce with special of them. Milling machines mainly refer to the lathe which u...Read more -

Basic structure of CNC drilling machine for tube sheet

The structure of CNC drilling machine for tube sheet : 1. The machine tool of the tube sheet CNC drilling machine adopts the form of fixed bed table and movable gantry. 2. The machine tool is mainly composed of the bed, worktable, gantry, power head, numerical control system, cooling system and o...Read more -

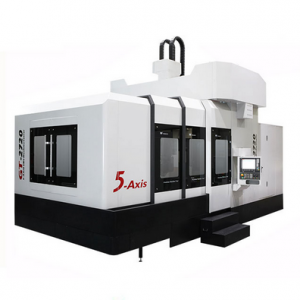

How to carry out detailed maintenance of large machining center?

Large profile machining center is a CNC boring and milling machine that combines the functions of CNC milling machine, CNC boring machine and CNC drilling machine, and is equipped with a tool magazine and an automatic tool changer. The spindle axis (z-axis) of the profile machining center is vert...Read more -

What fields can CNC drilling machines be used for?

CNC drilling machine is a universal machine tool with a wide range of uses, which can perform drilling, reaming, countersinking and tapping of parts. When the radial drilling machine is equipped with process equipment, it can also carry out boring; it can also mill the keyway with a multi-functi...Read more -

What to pay attention to when buying a heavy-duty lathe

Heavy machines mean heavier cuts, higher rigidity and less vibration. For longest life and highest precision, always choose a lathe with a heavy-duty cast iron base. Anything less than 2 hp or so is not enough for metal cutting. The chuck needs to be large enough to hold whatever workpiece the ma...Read more -

How do valve factories in China formulate operating procedures for valve special machines?

Valve special machines have the characteristics of high efficiency, stability, high precision and long life, which are favored by valve factories. More and more valve factories use valve special machines to produce and process valve workpieces. Let’s take a look at the safety operation rule...Read more -

How to choose CNC machine tool when machining valve parts

Selection principle of CNC machine tools when machining valve parts: ① The size of the machine tool should be compatible with the outline size of the valve to be processed. Large machine tools are used for large parts, so that the equipment can be used reasonably. A vertical lathe should b...Read more