News

-

What are the precautions when buying a machining center in Turkey

At present, there are countless brands of machining centers in the market of CNC machine tools, and there are also many models. So when we generally buy machining centers, to avoid detours, what should I pay attention to? The following points are for your reference: 1. Determine the nature of equ...Read more -

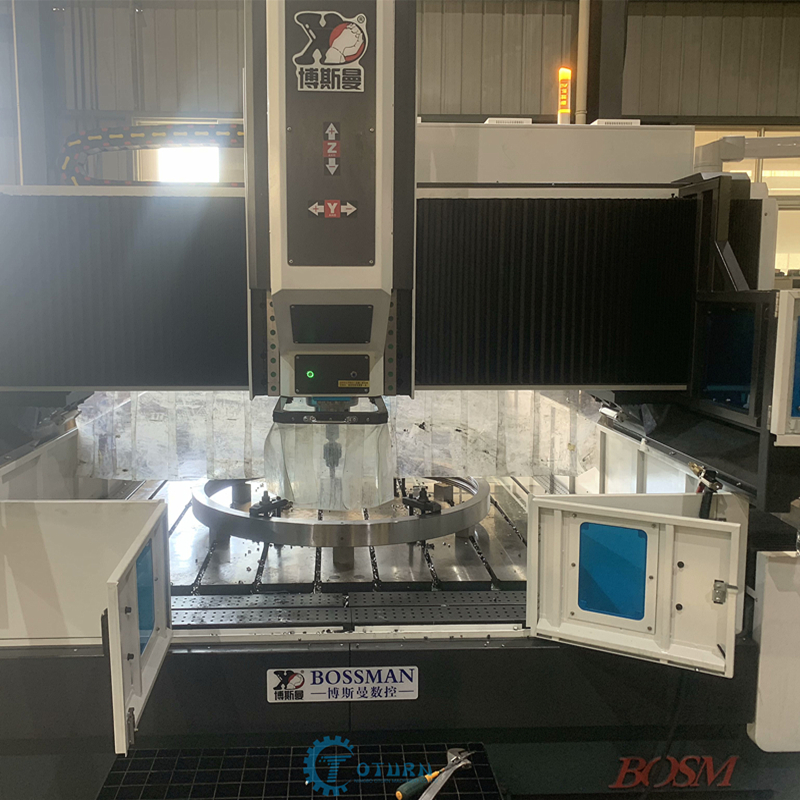

Four-jaw self-centering gantry drilling and milling machine BOSM1616 at the Iranian customer site

The BOSM1600*1600 four-jaw self-centering gantry drilling and milling machine are on the site of Iranian customers. Iranian customers mainly process slewing supports. Since Iranian customers bought this gantry drilling and milling machine, they immediately eliminated the processing technology of ...Read more -

A question asked by a Turkish customer a few days ago: Maintenance of the pneumatic system of CNC drilling machines

1. Remove impurities and moisture in the compressed air, check the oil supply of the lubricator in the system, and keep the system sealed. Pay attention to adjust the working pressure. Clean or replace the pneumatic failure and filter elements. 2. Strictly abide by the operation and daily mainte...Read more -

What are the advantages of the special valve machine over other machines?

Many people know that when processing a workpiece if the structure of a workpiece is more complex, it needs to be combined with many machine. In this process, it is necessary to adjust the machine from time to time. This is relatively troublesome when processing the workpiece, especially For cert...Read more -

What factors can cause problems with CNC drilling and milling machines

No matter how fast and efficient the CNC drilling and milling machine is, it is not absolutely reliable. Because there are problems with other types of machines, we may also inadvertently damage these machines. The following are our common problems. 1. Poor or improper maintenance CNC drilling a...Read more -

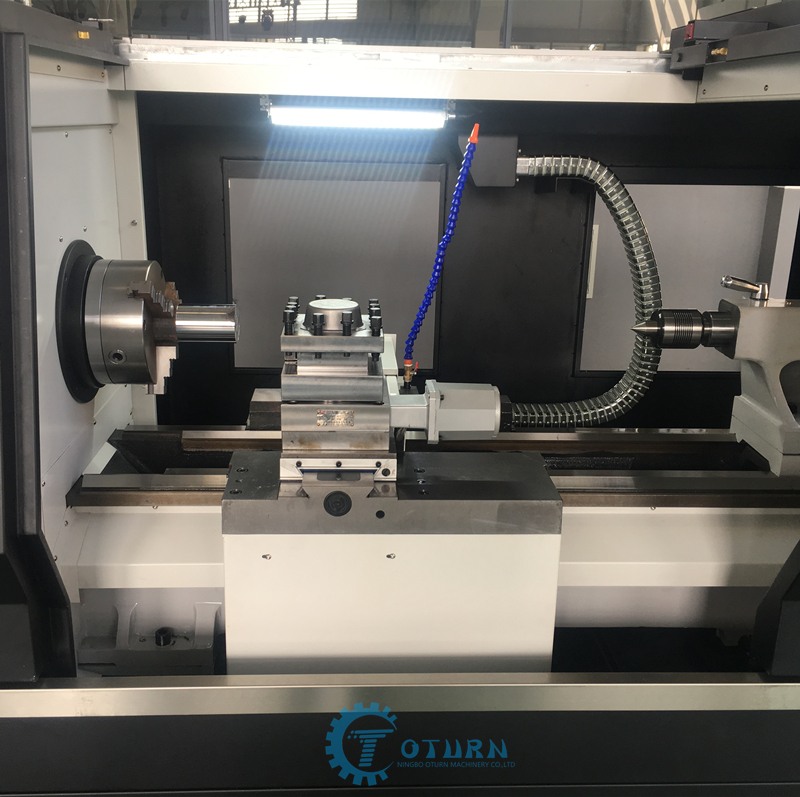

The big order is late. The chief programmer takes sick leave

The big order is late. The chief programmer takes sick leave. Your best customer just sent a text message asking for an offer that was due last Tuesday. Who has time to worry about the lubricating oil dripping slowly from the back of the CNC lathe, or wondering if the slight buzzing noise you hea...Read more -

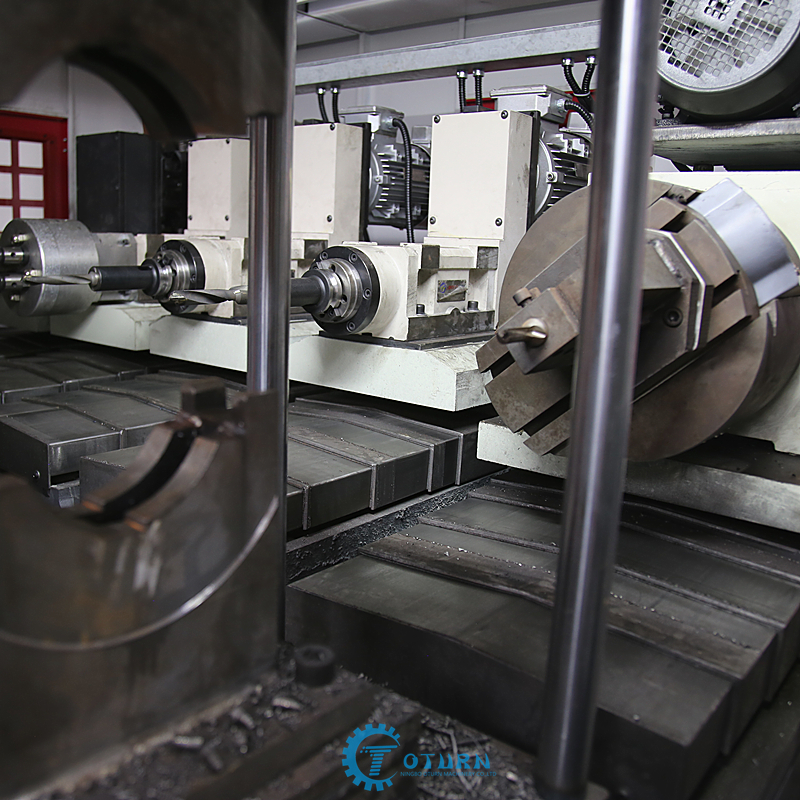

How to choose high-quality CNC pipe threading lathe

CNC pipe threading lathe is a kind of machinery and equipment used in the production and processing of the industry at this stage. With the increase in market demand and the increasing number of machine manufacturers in major cities, the quality problem has become more and more prominent. Then ev...Read more -

2020-2026 Global and China CNC Machine Tool Market Report

As a typical mechatronic product, CNC machine combine mechanical technology with CNC intelligence. The upstream mainly involves castings, sheet weldments, precision parts, functional parts, CNC systems, electrical components and other parts; the downstream is widely involved in machinery, molds, ...Read more -

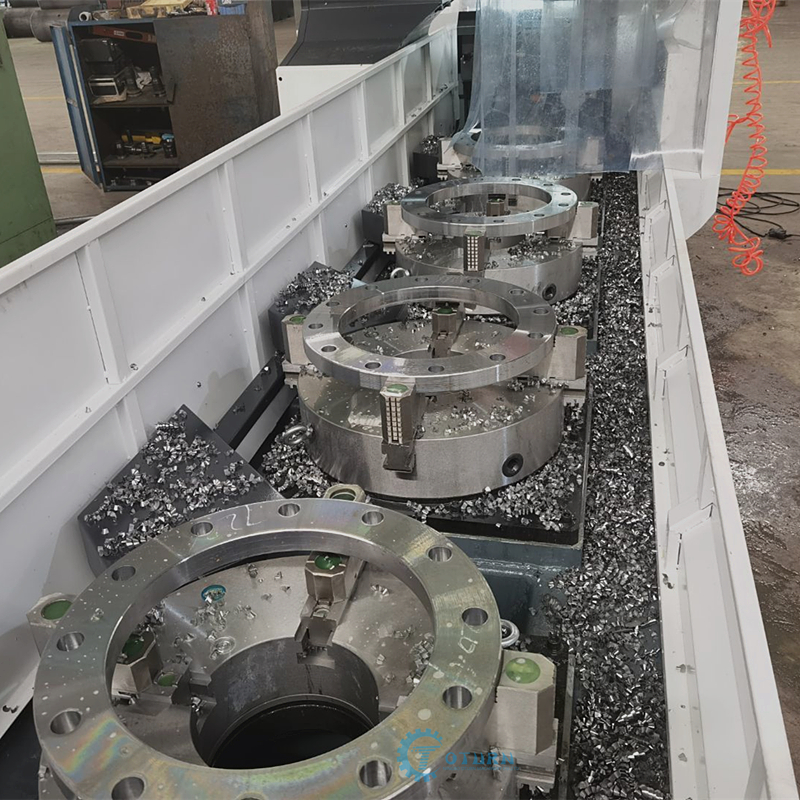

Four-station shaft flange drilling machine at the customer site

The BOSM S500 four-station shaft flange drilling machine is on the customer’s site. The customer’s previous processing of workpieces was done with old-fashioned radial drills, which was time-consuming and laborious, and the labor cost was high, and the efficiency was low. Our four The four-statio...Read more -

CNC milling is one of the available CNC services

CNC milling is one of the available CNC services. This is a subtractive production method because you will use this process to develop products with the help of special machines, which will remove parts from a block of material. Of course, the machine will use a special tool to cut off part of th...Read more -

What are the advantages of CNC pipe threading lathes?

The CNC pipe threading lathe is an important equipment for pipe processing, which is mainly designed and manufactured for the processing requirements of oil pipelines, casings and drill pipes in the petroleum, chemical, and metallurgical industries. After several years of development, CNC pipe th...Read more -

2020-2027 Computer Numerical Control (CNC) Machine Market Competitive Intelligence and Tracking Report in Turkey

A new market study was released on the computer numerical control (CNC) machine market in 2021, which contains data tables of historical and forecast years, expressed in chat and graphs, and provides easy-to-understand detailed analysis. The report also sheds light on the current situation and up...Read more -

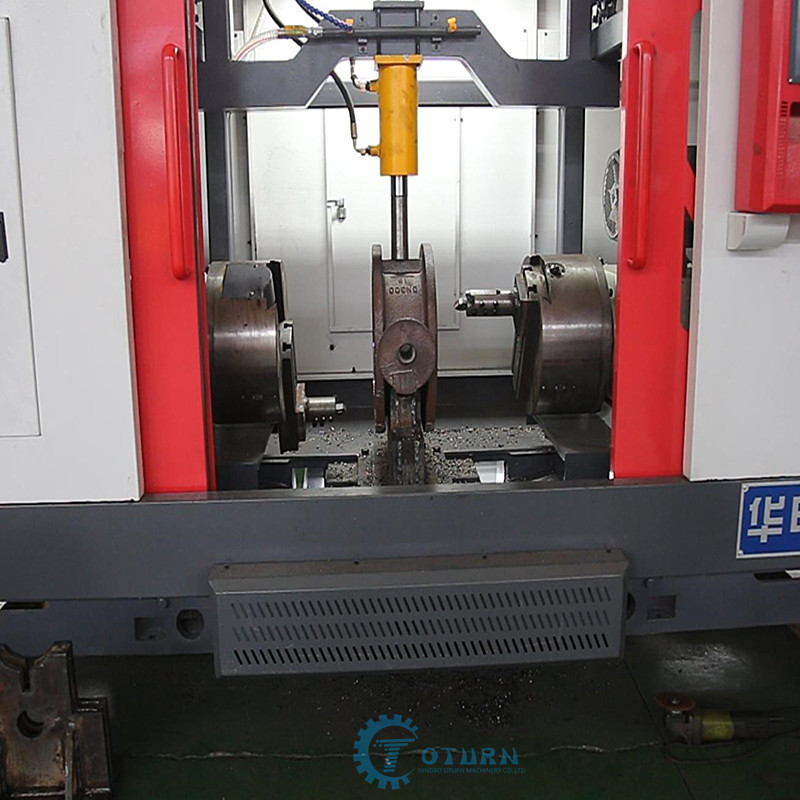

8 CNC Drilling And Milling Machines at the customer site

As shown in the picture, BOSM’s 8 CNC Drilling And Milling Machines are being processed by customers in Yantai. In October last year, Yantai customers ordered 3 CNC Drilling And Milling Machines at one time. The CNC Drilling And Milling Machines are more efficient than the previous manually...Read more -

The 5-axis CNC machining center market will show unparalleled growth from 2020 to 2025

by region outlook (North America, Europe, Asia Pacific, South America and the Middle East and Africa), top manufacturers, growth potential, price trends, competitive market share for 2019-2024 and forecasts are added by Market Study Report LLC. A new research report claims that the 5-axis CNC ma...Read more -

Summary and classification of butterfly valves

The butterfly valve was previously positioned as a leakage valve and was only used as a valve plate. It was not until 1950 that synthetic rubber was actually used, and synthetic rubber was applied to the seat ring of the butterfly valve, and the butterfly valve as a cut-off valve made its debut. ...Read more -

2021 4-axis CNC machining center market segmentation and recent trend analysis, regional data consumption, development, survey, growth to 2025

Market overview. The global 4-axis CNC machining center market is expected to grow in the forecast period from 2021 to 2025. The compound annual growth rate during the forecast period from 2021 to 2025 is expected to reach USD by 2025. Year dollar The four-axis CNC machining center market report ...Read more