Manual Vertical Turning Lathe Manufacturer in China for Precision Engineering

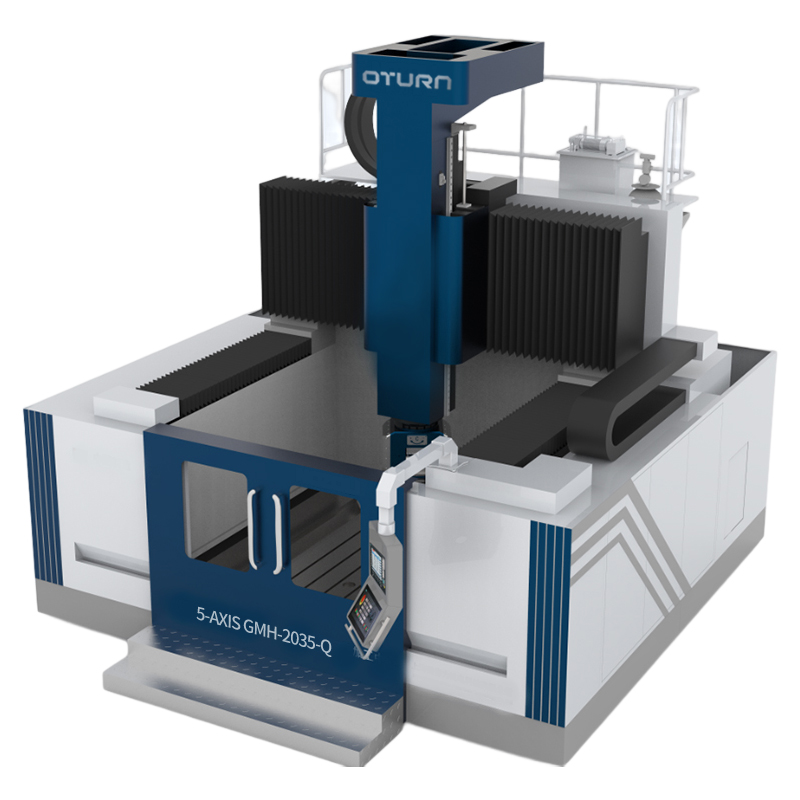

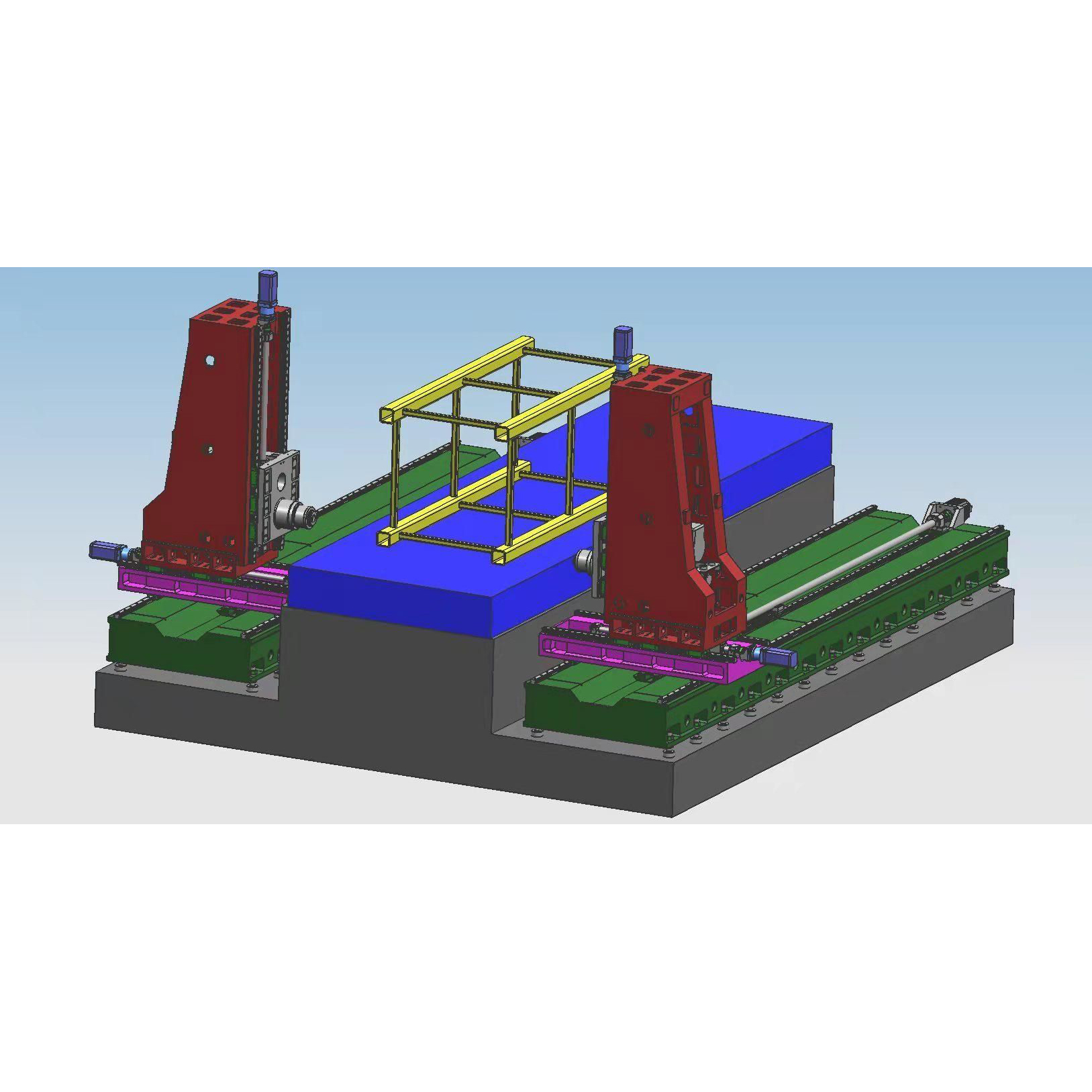

I’m excited to share with you our top-of-the-line Manual Vertical Turning Lathe, designed specifically for manufacturers in China seeking superior quality and precision. This lathe combines advanced engineering with the simplicity of manual operation, making it an ideal choice for businesses aiming to streamline their production processes. With sturdy construction and user-friendly controls, this machine is perfect for various machining tasks, ensuring you get the accuracy you need for your projects. Our Manual Vertical Turning Lathe stands out in the market as a reliable solution for those looking to enhance productivity without compromising on performance. Whether you’re working on small-scale projects or larger manufacturing runs, our lathe can adapt to your needs with ease. We’ve put countless hours into refining our design, ensuring it meets the high standards that professionals expect. Partner with us to elevate your manufacturing capabilities and drive your business forward!

Manual Vertical Turning Lathe Your Trusted OEM Partner Supplies the World\u2019s Top Brands

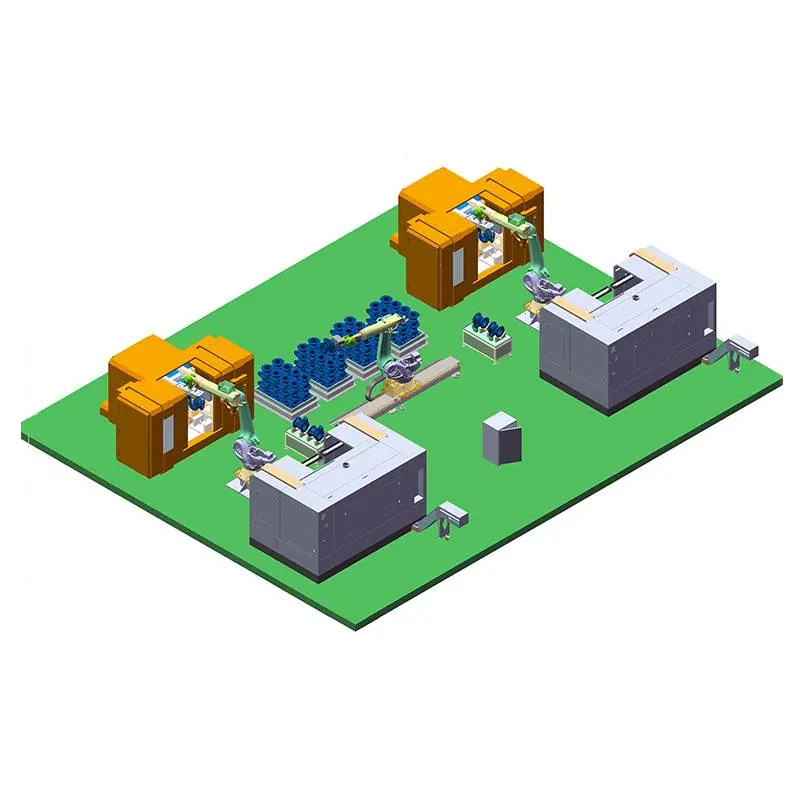

In the world of manufacturing, having the right machinery can significantly impact production efficiency and product quality. One of the essential tools in many workshops and factories is the manual vertical turning lathe. This versatile machine is known for its ability to handle heavy workpieces and provide precise machining capabilities. For businesses looking to optimize their operations, partnering with a trusted OEM supplier for such machinery becomes crucial. Our manufacturing facility specializes in delivering high-quality manual vertical turning lathes designed to meet the stringent requirements of the global market. With a focus on durability, precision, and user-friendliness, our lathes are engineered to support diverse applications, from heavy industry to intricate components. By leveraging advanced manufacturing techniques and stringent quality control processes, we ensure that each machine not only meets but exceeds industry standards, thus serving our clients' operational needs effectively. Collaborating with a reliable OEM partner means gaining access to customized solutions tailored to the specific demands of your business. Our commitment to innovation and excellence empowers clients to enhance their production capabilities, ensuring they can confidently serve their customers. By investing in our manual vertical turning lathes, companies can expect to boost their performance, reduce downtime, and ultimately increase profitability—making us your ideal partner in success.

Manual Vertical Turning Lathe - Your Trusted OEM Partner Supplies the World’s Top Brands

| Feature | Specifications | Applications | Advantages |

|---|---|---|---|

| Max Swing Diameter | 900 mm | Heavy Industry, Aerospace | High precision machining |

| Spindle Speed | 45-300 rpm | Railway, Marine | Robust construction |

| Machine Weight | 5000 kg | Energy Sector, automotive | Durable and reliable |

| Control System | CNC | Manufacturing, Tooling | User-friendly interface |

| Power Consumption | 15 kW | General Engineering | Energy efficient |

Related Products