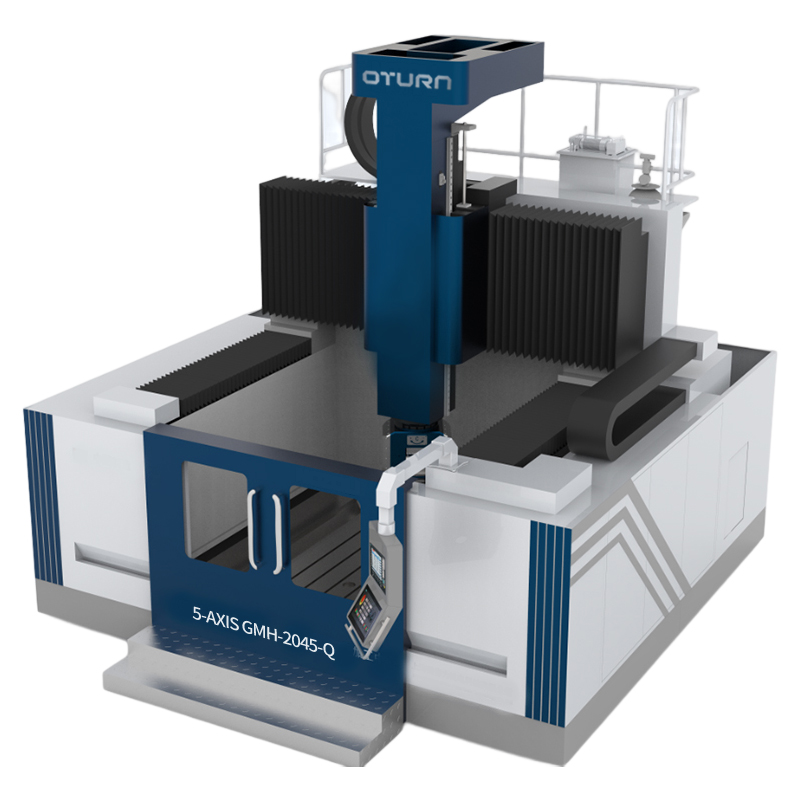

China Manufacturer of Advanced Machine for Valve Body Solutions

When it comes to sourcing the right machine for valve body manufacturing, I know how crucial it is to partner with a reliable manufacturer. Our machine for valve body is designed to deliver precision and efficiency, meeting the needs of the most demanding production lines. I pay close attention to the quality of our equipment, ensuring it's built with durability in mind to withstand heavy use. Sourcing from a trusted China manufacturer means you get competitive pricing without sacrificing quality. I understand that reducing costs while maintaining production standards is essential for your business. Furthermore, our advanced technology enables faster turnaround times, allowing you to meet tight deadlines and increase your output. Let’s connect and discuss how our machine for valve body can enhance your manufacturing capabilities. I’m here to provide personalized solutions that fit your specific requirements and help you streamline your production processes.

Machine For Valve Body Now Trending Your End-to-End Solution

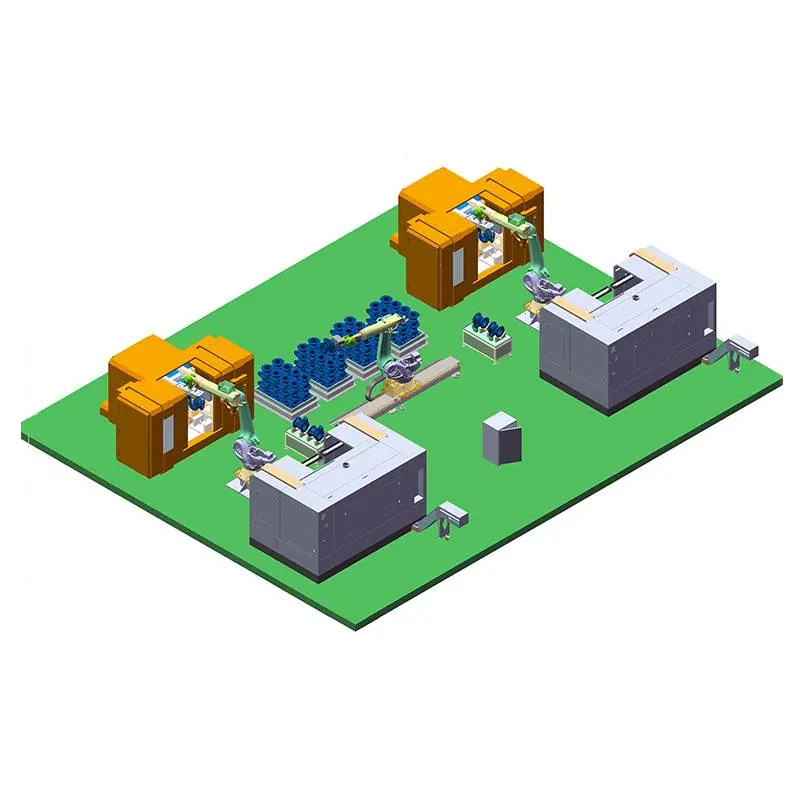

In today's fast-paced manufacturing environment, ensuring efficiency and quality in valve body production is crucial for meeting global demand. The trend towards specialized machinery for valve bodies highlights the industry's shift towards automation and precision engineering. As procurement professionals look to enhance their production lines, investing in advanced machinery can significantly reduce lead times and improve product quality. These machines not only streamline the manufacturing process but also incorporate state-of-the-art technology to ensure consistency and reduce waste. The rise of automated solutions offers an end-to-end production capability, from initial design to final product delivery. This integrated approach allows manufacturers to maintain control over the entire production cycle, ensuring that each valve body meets the stringent standards required in various industries, including oil and gas, automotive, and water management. By embracing these innovations, businesses can respond more effectively to market changes, adapt to customer needs, and enhance their competitive edge in the global marketplace. Choosing the right machine for valve body production is a vital step toward achieving operational excellence. As companies navigate the complexities of sourcing machinery and technology, they can benefit from expert guidance on selecting equipment that aligns with their production goals. Investing in cutting-edge machinery not only facilitates improved operational efficiency but also positions firms to capture new opportunities in an ever-evolving industry landscape.

Machine For Valve Body Now Trending Your End-to-End Solution

| Feature | Description | Application Area | Technology | Efficiency |

|---|---|---|---|---|

| Automated Production | Fully automated system for high-volume production | Manufacturing | AI and Machine Learning | Up to 95% |

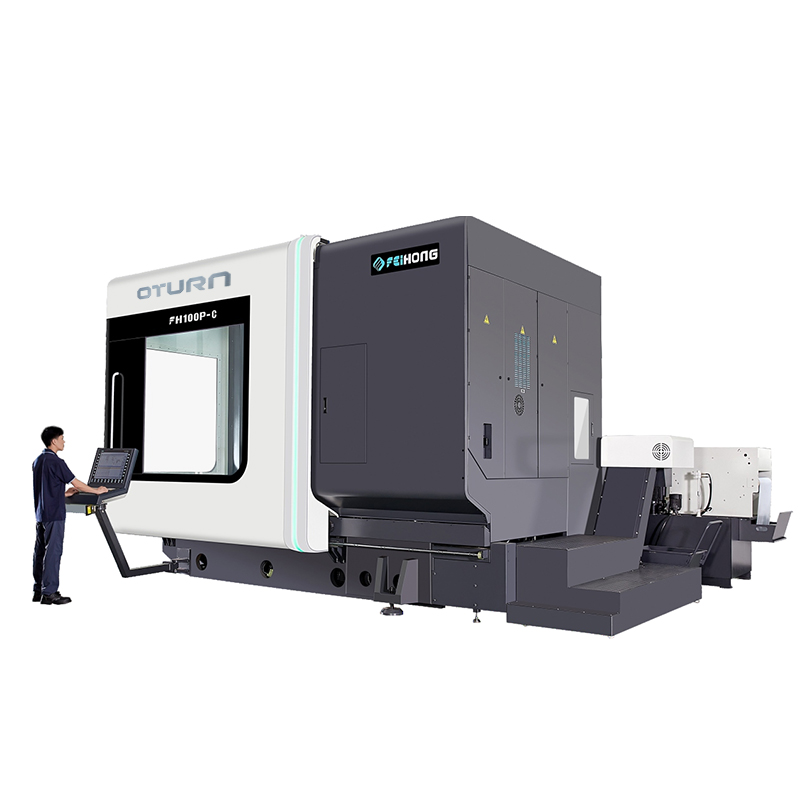

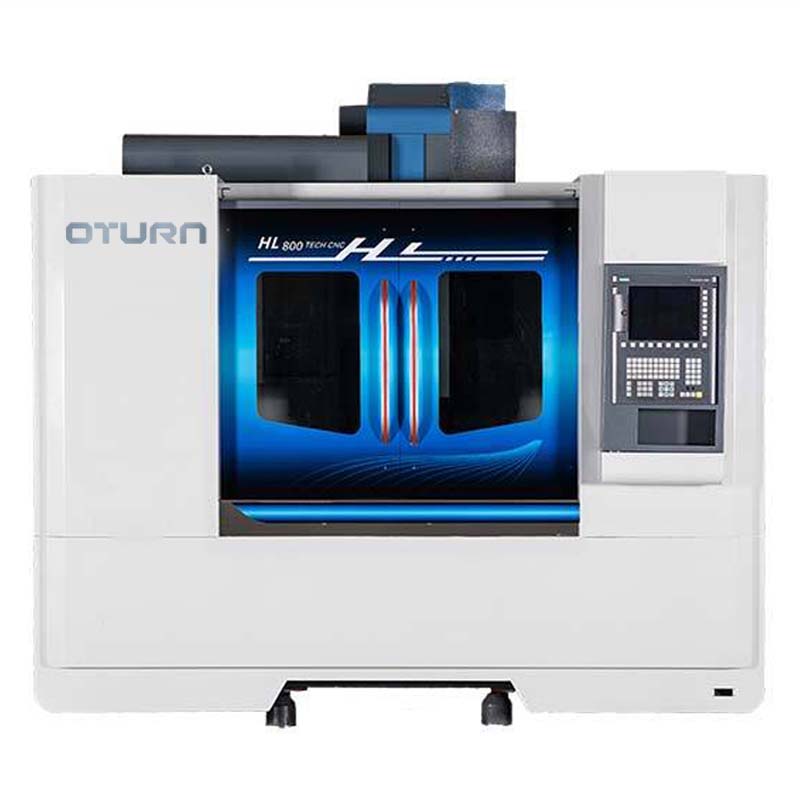

| Precision Engineering | High precision components for valve bodies | Aerospace, Automotive | CNC Machining | 99% |

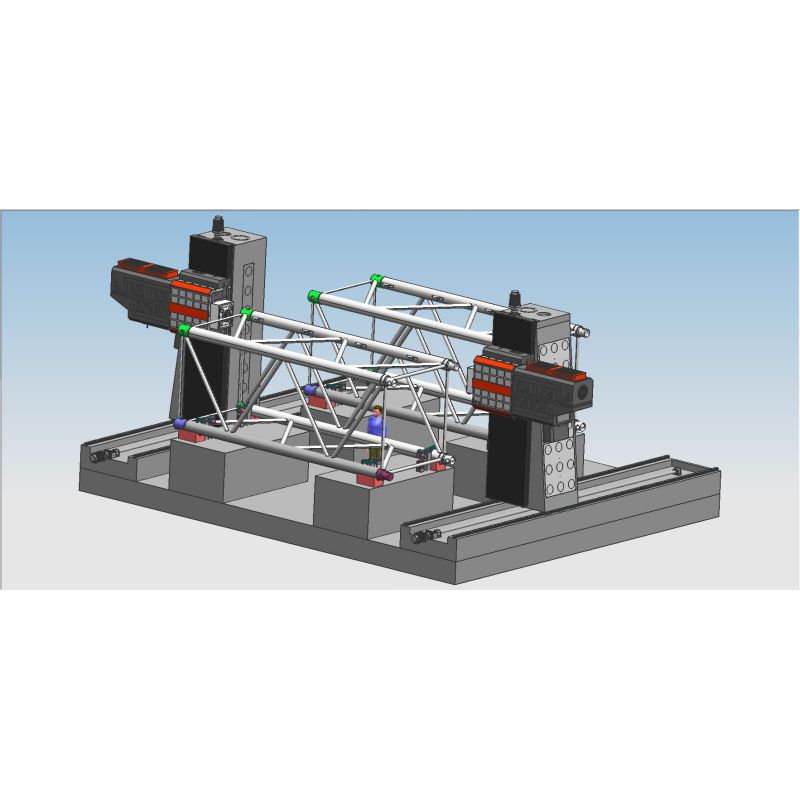

| Robust Durability | Designed to withstand extreme conditions | Industrial Applications | Advanced Materials | 85% |

| User-Friendly Interface | Intuitive controls for ease of operation | All Industries | Touchscreen Technology | N/A |

| Energy Efficiency | Low energy consumption during operation | Green Manufacturing | Hybrid Technology | 90% |

Related Products