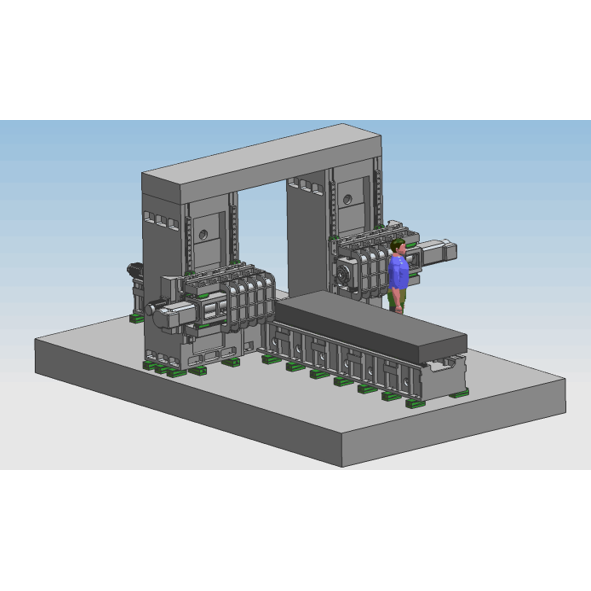

Top China Manufacturer of Five Axis CNC Milling Machines

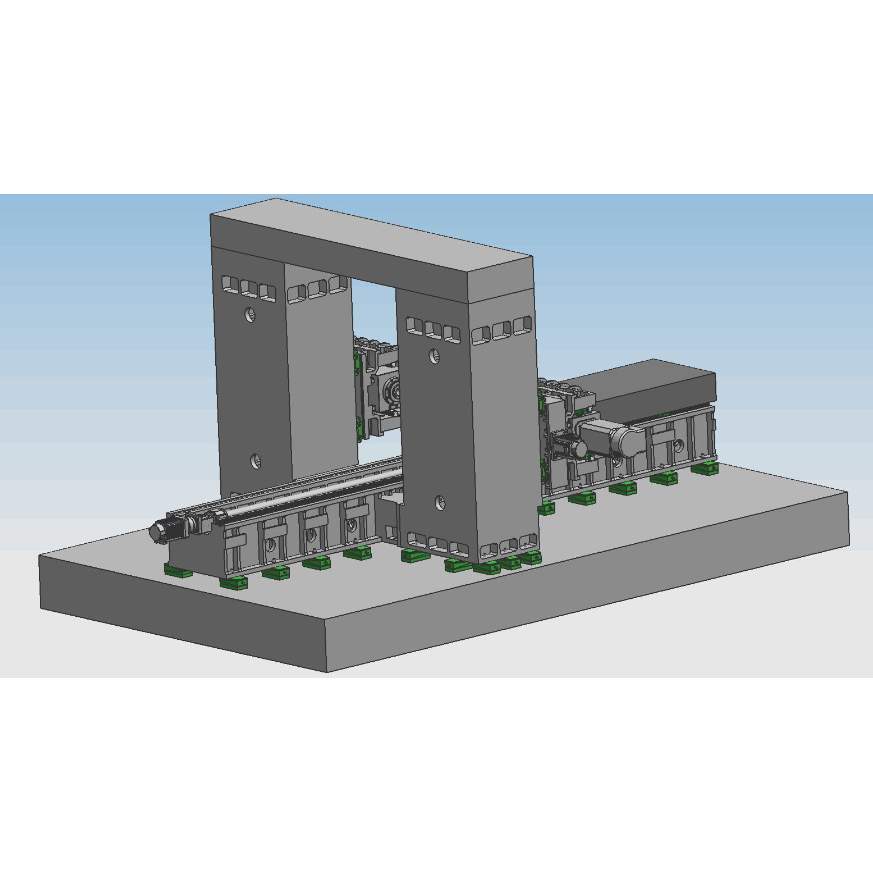

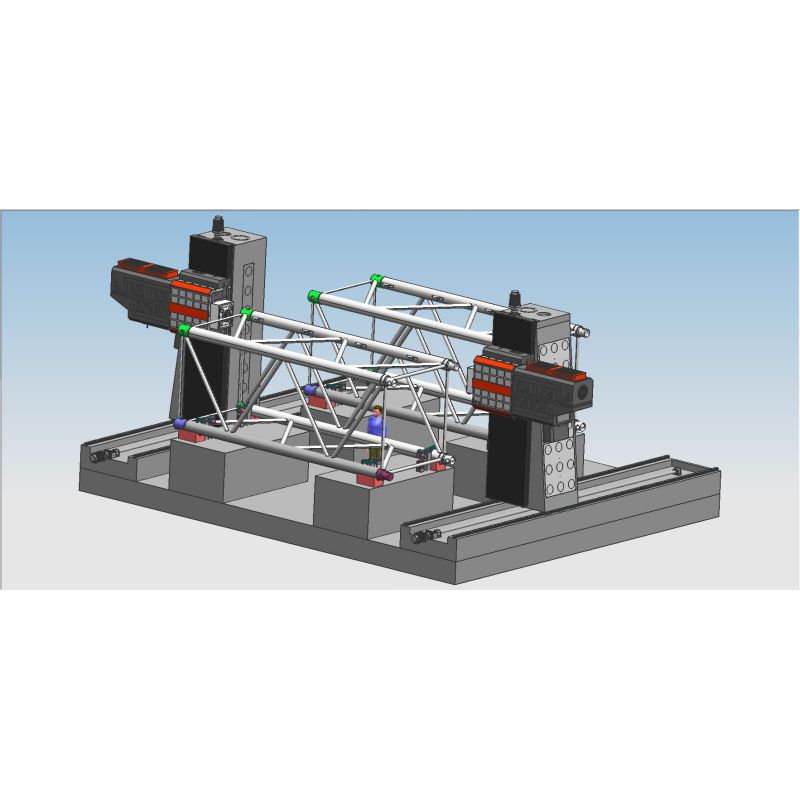

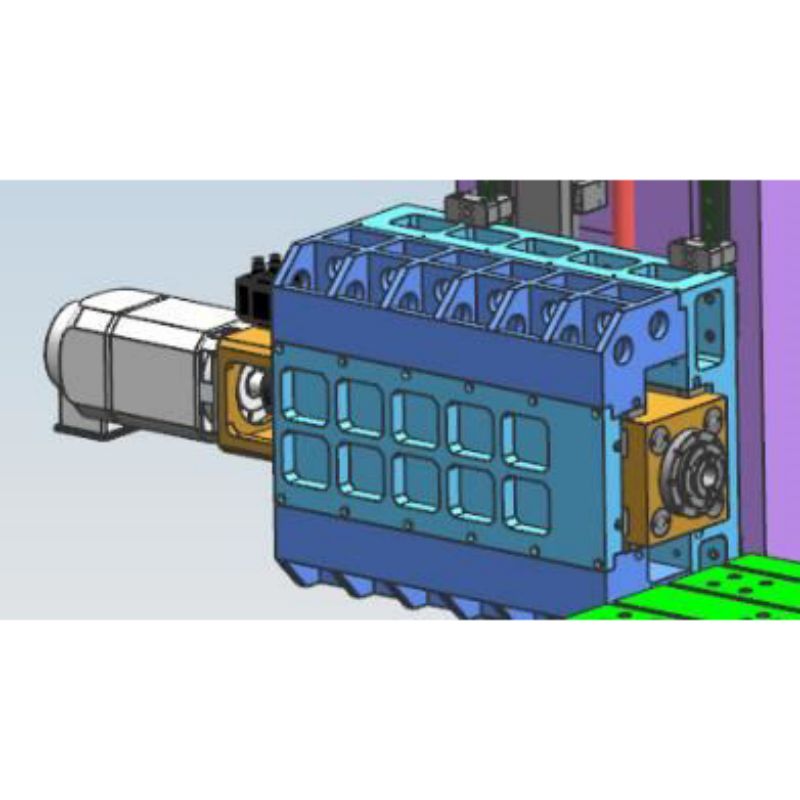

When I think about optimizing precision in machining, the Five Axis CNC Milling Machine stands out, especially for industries sourcing from China. This innovative equipment allows me to handle complex geometries with unmatched accuracy and efficiency. As a manufacturer, I understand the importance of reliable machinery that enhances productivity and reduces lead times. This milling machine is designed to move in five different directions simultaneously, making it ideal for intricate parts and components. With its robust construction and advanced technology, it ensures superior surface finishes and tight tolerances. I appreciate how this machine not only boosts my operational capabilities but also drives down production costs. For anyone looking to elevate their machining processes, partnering with a leading manufacturer in China for a Five Axis CNC Milling Machine can be a game changer. Let’s enhance our production dimensions together!

Five Axis Cnc Milling Machine Industry Leaders Supplies the World\u2019s Top Brands

In the rapidly evolving landscape of precision engineering, five-axis CNC milling machines have become a cornerstone of advanced manufacturing. Suppliers in this industry play a pivotal role in equipping businesses globally with the capabilities to produce intricate components that meet the highest standards of quality and efficiency. These machines enable manufacturers to achieve complex geometries in a single setup, significantly reducing production time and increasing accuracy. As the demand for precision parts grows across sectors such as aerospace, automotive, and medical devices, the leading suppliers are committed to innovation, ensuring that their offerings not only meet but exceed industry expectations. Furthermore, these industry leaders emphasize the importance of providing comprehensive support to their clients. From initial consultations to after-sales service, the focus is on fostering long-term partnerships that enhance productivity and drive technological advancements. By integrating the latest in automation and software solutions, these suppliers are crucial in helping manufacturers navigate the challenges of modern production demands. For global buyers, investing in five-axis CNC milling technology is not merely a purchase; it is a strategic move towards operational excellence and a competitive edge in their respective markets. Ultimately, as manufacturing processes become increasingly sophisticated, collaborating with top-tier suppliers in the five-axis CNC milling machine sector will empower businesses to harness the full potential of their production capabilities, paving the way for greater innovation and market leadership. By choosing the right partners, manufacturers can ensure they remain at the forefront of technological advancements, driving efficiency and quality in their operations.

Five Axis Cnc Milling Machine Industry Leaders Supplies the World’s Top Brands

| Brand | Country | Market Share (%) | Technology Level | Year Established |

|---|---|---|---|---|

| Brand A | USA | 25 | High | 1985 |

| Brand B | Germany | 20 | High | 1990 |

| Brand C | Japan | 15 | Medium | 2000 |

| Brand D | Switzerland | 10 | High | 1995 |

| Brand E | South Korea | 8 | Medium | 2010 |

Related Products