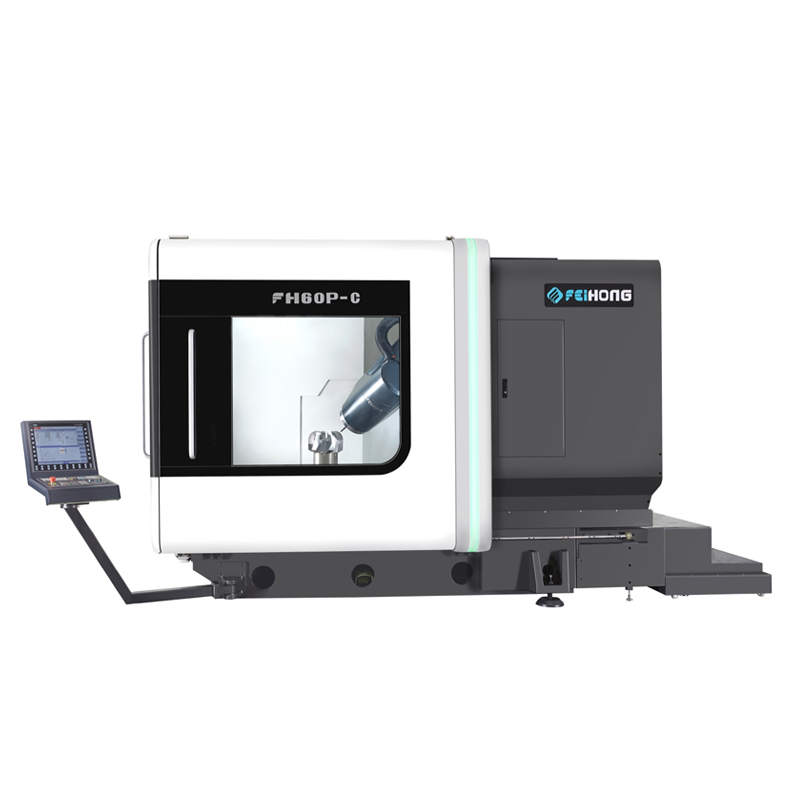

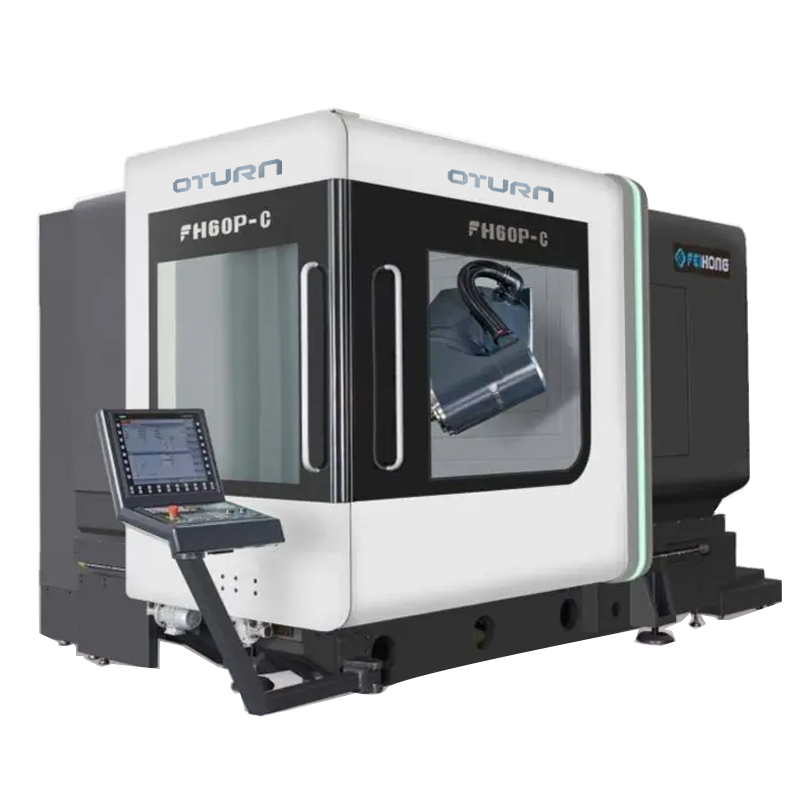

Double Spindle CNC Lathe Manufacturer in China for Precision Machining

When I think about precision and efficiency in machining, the Double Spindle CNC Lathe stands out in the market. Designed for high-volume production, this machine enhances productivity by allowing simultaneous operations on two sides of a workpiece. As a manufacturer based in China, I understand the importance of reliability and quality in your production processes. Our Double Spindle CNC Lathe is engineered for durability and precision, ensuring you achieve the finest results in your machining tasks. With advanced programming capabilities, it allows for versatile applications, making it an ideal choice for various industries. If you’re looking to optimize your operations and lower production costs, our lathe could be your perfect solution. I’m confident that investing in this technology will bring significant returns and elevate your manufacturing capabilities. Let’s elevate your business together with our high-performance equipment!

Double Spindle Cnc Lathe Industry Giant More Than a Supplier - A Partner

In today's competitive manufacturing landscape, choosing a reliable partner in the double spindle CNC lathe industry is more crucial than ever. As businesses worldwide seek to enhance their production efficiency and precision, they often look for suppliers who offer not just machinery, but comprehensive support and innovative solutions. This is where a strategic partnership becomes invaluable. By collaborating with a partner that understands the intricacies of the industry, businesses can access advanced technologies, customized solutions, and tailored services that elevate their operations. A partner in the CNC lathe segment goes beyond merely providing equipment; they invest in understanding your unique manufacturing needs. This collaboration allows for frequent feedback loops and adjustments, ensuring that the machinery adapts to evolving industry demands. The synergy created through a partnership fosters growth, increases production efficiency, and ultimately drives profitability. Whether it's the development of new features or the integration of the latest technologies, a dedicated partner stands by your side throughout the entire manufacturing journey. Moreover, the benefits of this partnership extend beyond operational efficiencies. A strong relationship fosters trust and mutual respect, leading to long-term collaboration that can weather market fluctuations. Together, both parties can explore new markets, develop innovative products, and adapt to changing consumer demands. For global buyers looking to enhance their manufacturing capabilities, forming a solid partnership in the double spindle CNC lathe industry is the key to unlocking a new level of success and sustainability.

Double Spindle Cnc Lathe Industry Giant More Than a Supplier - A Partner

| Dimension | Value | Description |

|---|---|---|

| Max Spindle Speed | 6000 RPM | Highest speed achieved by the lathe for precision work. |

| Machine Weight | 2500 kg | Ensures stability during operation and reduces vibrations. |

| Tool Holder Capacity | 12 Tools | Allows for quick tool changes and versatility in machining. |

| Max Turning Diameter | 350 mm | Great for larger components requiring precision machining. |

| CNC Control Type | G-code compliant | Allows for wide compatibility with various CAD/CAM programs. |

| Cooling System Type | Closed-loop | Ensures consistent temperature and stable machining conditions. |

Related Products