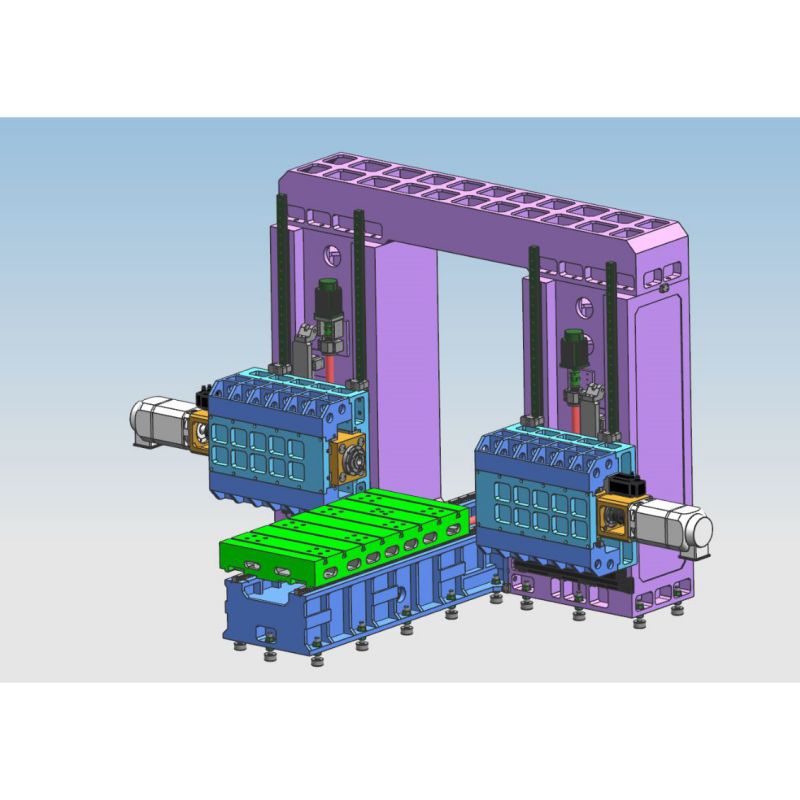

CNC Vertical Milling: Leading Manufacturer in China for Precision Solutions

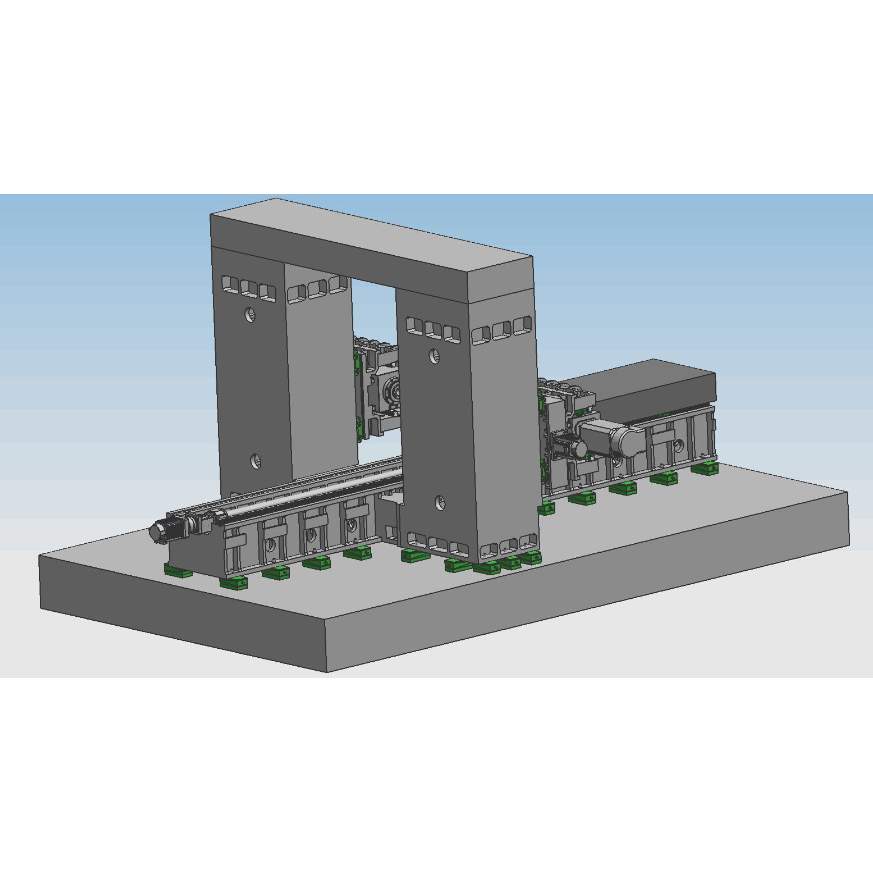

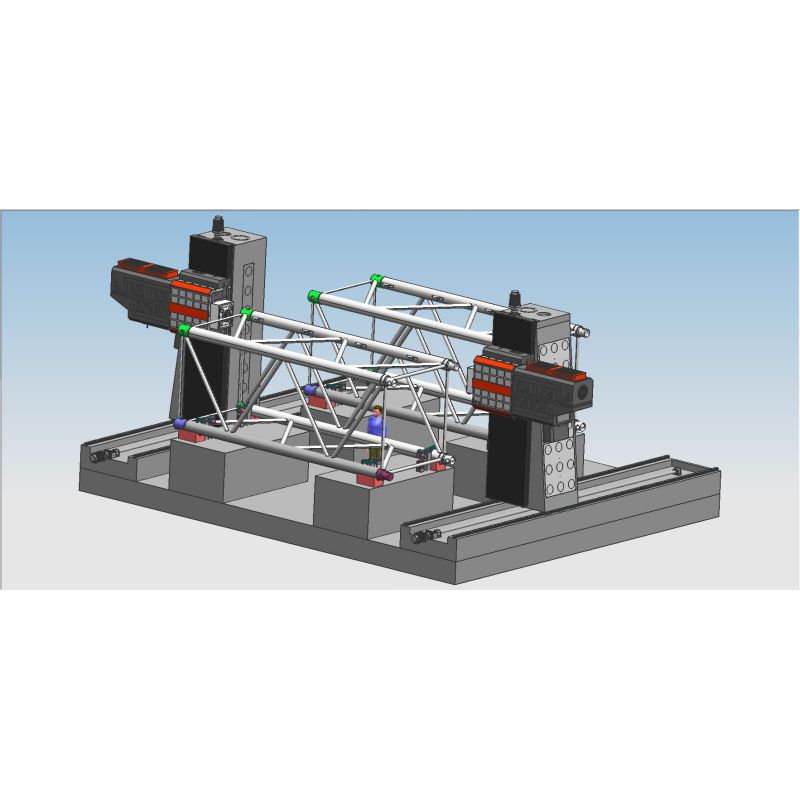

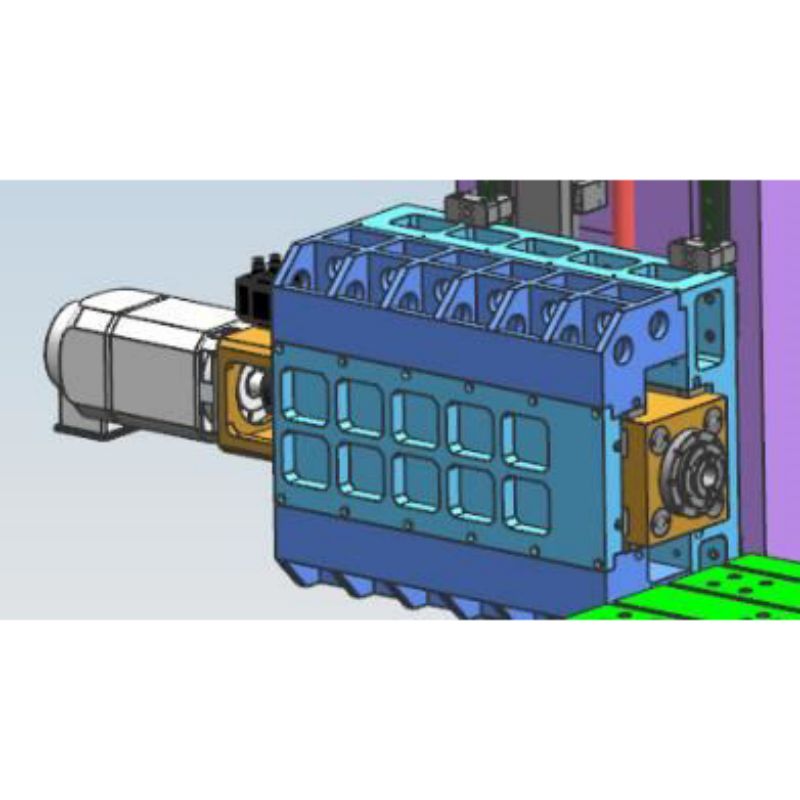

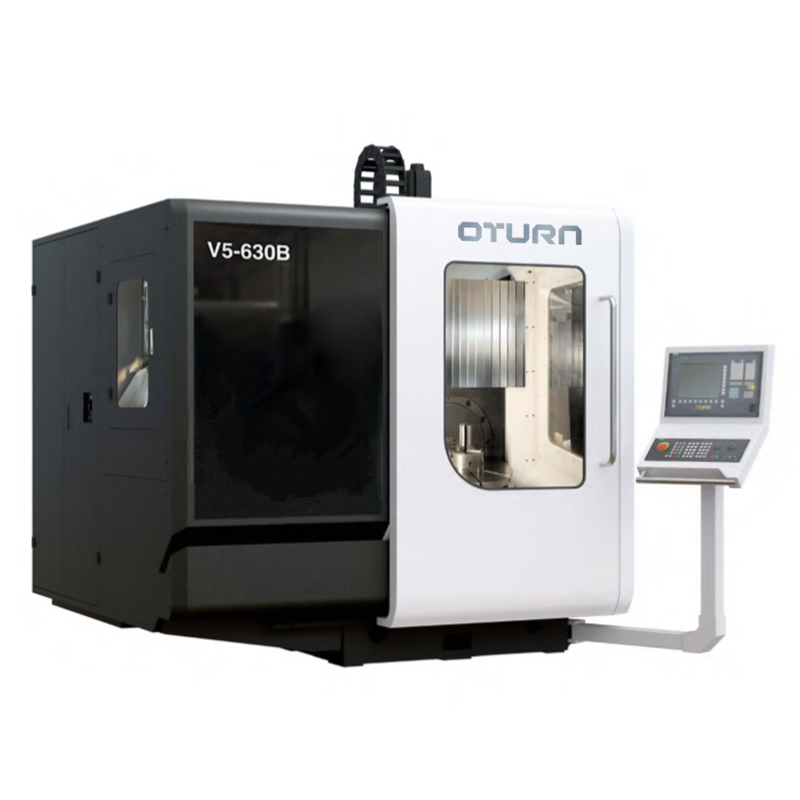

When I think about CNC Vertical Milling, I immediately recognize its importance for precision machining in various industries. As a manufacturer based in China, I take pride in delivering high-quality CNC Vertical Milling machines that enhance productivity and accuracy in your operations. Our machines are designed with advanced technology to ensure smooth and efficient milling processes, making them ideal for both small and large-scale production. I understand that as a B2B purchaser, you need reliable equipment that meets your specific requirements. That's why our CNC Vertical Milling machines are customizable, allowing you to tailor features according to your operational needs. With a commitment to excellence and customer satisfaction, I strive to provide the best value for your investment. If you’re seeking a trusted partner in your manufacturing journey, let’s connect and explore how our machines can elevate your production capabilities.

CNC Vertical Milling Delivers Unmatched Quality Exceeds Industry Benchmarks

CNC vertical milling has emerged as a cornerstone in modern manufacturing, offering precision and quality that set industry standards. This advanced machining technique allows for intricate designs and meticulous tolerances, making it ideal for various applications, from aerospace to automotive. The combination of automated processes and skilled craftsmanship results in products that not only meet but exceed global benchmarks, ensuring reliability and performance under the most demanding conditions. What sets CNC vertical milling apart is its ability to adapt to specific project needs while maintaining output consistency. Procurement specialists across the globe appreciate the efficiency and reduced lead times that come with this technology. As industries evolve, the demand for high-quality components continues to rise, pushing manufacturers to embrace cutting-edge techniques that guarantee superior outcomes. By leveraging CNC vertical milling, companies can remain competitive in an increasingly complex market landscape. Investing in CNC vertical milling technology is a strategic move for businesses seeking exceptional quality in their manufacturing processes. The precision and versatility offered empower manufacturers to innovate and respond proactively to market changes, fostering sustainable growth. As industries require stringent adherence to quality standards, CNC vertical milling becomes not just an option but a necessity for procurement leaders aiming for excellence in their supply chains.

CNC Vertical Milling Delivers Unmatched Quality Exceeds Industry Benchmarks

| Parameter | Measurement | Industry Benchmark | Performance |

|---|---|---|---|

| Machining Precision | ±0.005 mm | ±0.01 mm | Above Benchmark |

| Surface Finish | Ra 0.8 µm | Ra 1.6 µm | Above Benchmark |

| Cycle Time | 45 min | 60 min | Below Benchmark |

| Material Removal Rate | 120 cm³/min | 100 cm³/min | Above Benchmark |

| Energy Consumption | 5 kWh | 7 kWh | Below Benchmark |

Related Products