Top China Manufacturer of CNC Vertical Drilling Machines for Precision Needs

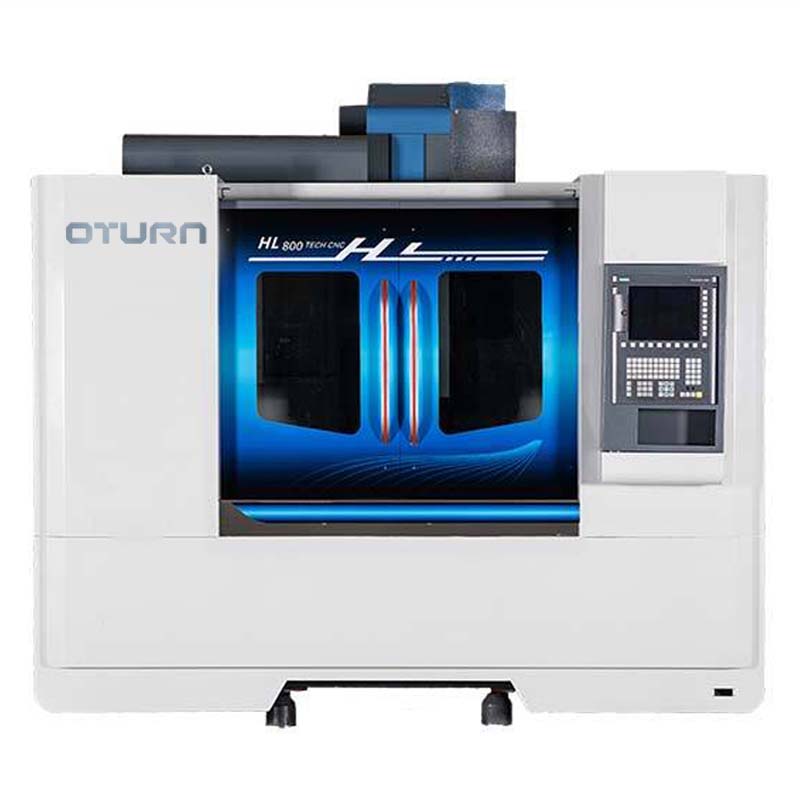

When searching for a **CNC Vertical Drilling Machine**, I know how vital it is to find a reliable and efficient solution. As a manufacturer based in China, we pride ourselves on delivering top-notch machines that enhance productivity and precision. Our CNC Vertical Drilling Machines are built with advanced technology, ensuring they meet the high demands of various industries. I understand that every B2B purchaser values quality and dependability, which is why our machines undergo rigorous testing and quality control. With customizable options, we cater to different drilling requirements, making it easier for you to streamline your operations. Choosing our products means partnering with a manufacturer committed to supporting your business growth. Let’s elevate your production capabilities together with our innovative solutions designed for performance and longevity. Reach out today to learn more about how our CNC Vertical Drilling Machines can benefit your operations in the competitive market.

Cnc Vertical Drilling Machine Products Service

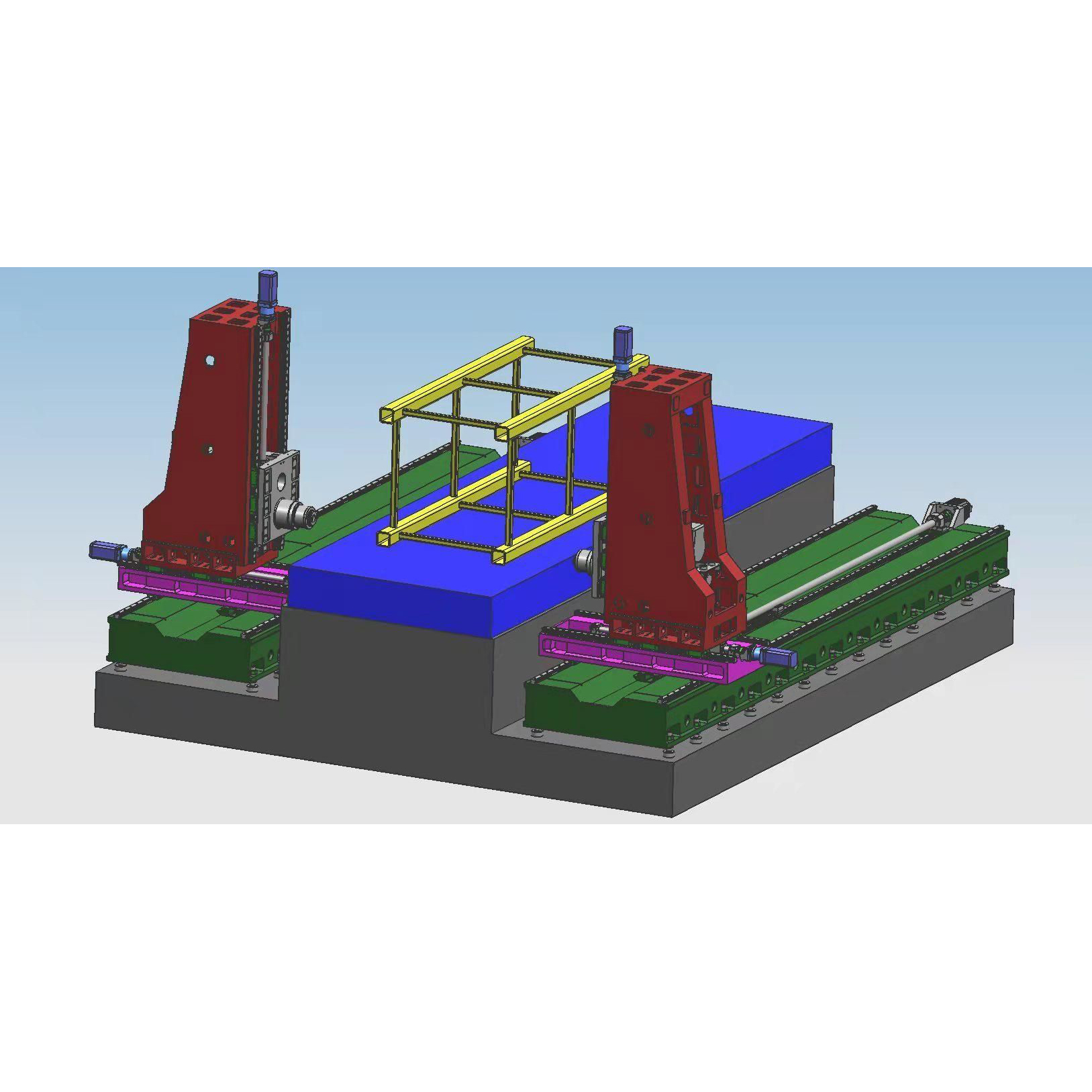

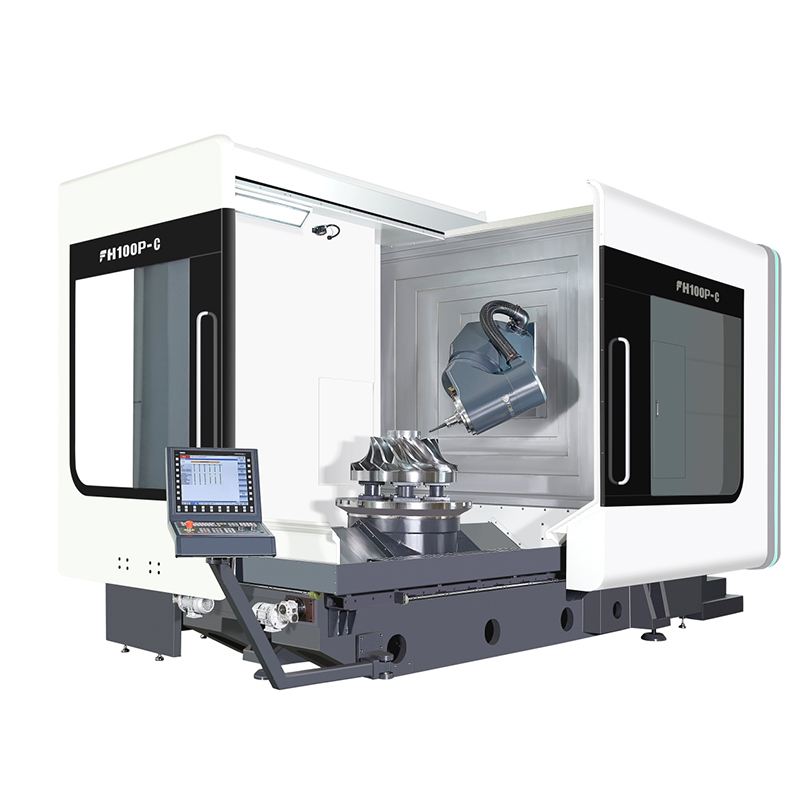

In the world of manufacturing, precision and efficiency are paramount. Vertical drilling machines have established themselves as indispensable tools in various industries, offering unparalleled accuracy for complex drilling operations. These machines are specifically designed to enhance productivity, making them essential assets for businesses looking to streamline their manufacturing processes. By investing in state-of-the-art designs and innovative technology, manufacturers can ensure that their vertical drilling machines meet the evolving demands of the global market. When selecting a vertical drilling machine, it’s crucial to consider factors such as versatility, control options, and ease of maintenance. Modern machines often come equipped with advanced numerical controls that allow for fine-tuning and automation, significantly reducing setup times and minimizing human error. Additionally, features like adjustable spindle speeds and multiple drilling capabilities increase the machine's adaptability across various materials, from metal to composite. Such features are vital for businesses aiming to enhance their production lines while maintaining high-quality standards. To support global sourcing efforts, companies can leverage a robust after-sales service and comprehensive support network. This ensures that procurement decisions are backed by reliable technical assistance, timely maintenance, and readily available spare parts, ultimately prolonging the machine's lifespan and optimizing its performance. With the right vertical drilling machine in hand, manufacturers can elevate their productivity, drive operational excellence, and maintain a competitive edge in the dynamic marketplace.

Cnc Vertical Drilling Machine Products Service

| Product Name | Model | Power (KW) | Drilling Depth (mm) | Weight (kg) | Service Type |

|---|---|---|---|---|---|

| CNC Vertical Drill | VDR-200 | 3.5 | 200 | 250 | Installation & Maintenance |

| Precision Vertical Drill | PVD-300 | 5.0 | 300 | 350 | Repair & Spare Parts |

| Heavy-Duty Vertical Drill | HVD-400 | 7.5 | 400 | 450 | User Training |

| Compact Vertical Drill | CVD-150 | 2.2 | 150 | 200 | On-Site Support |

Related Products