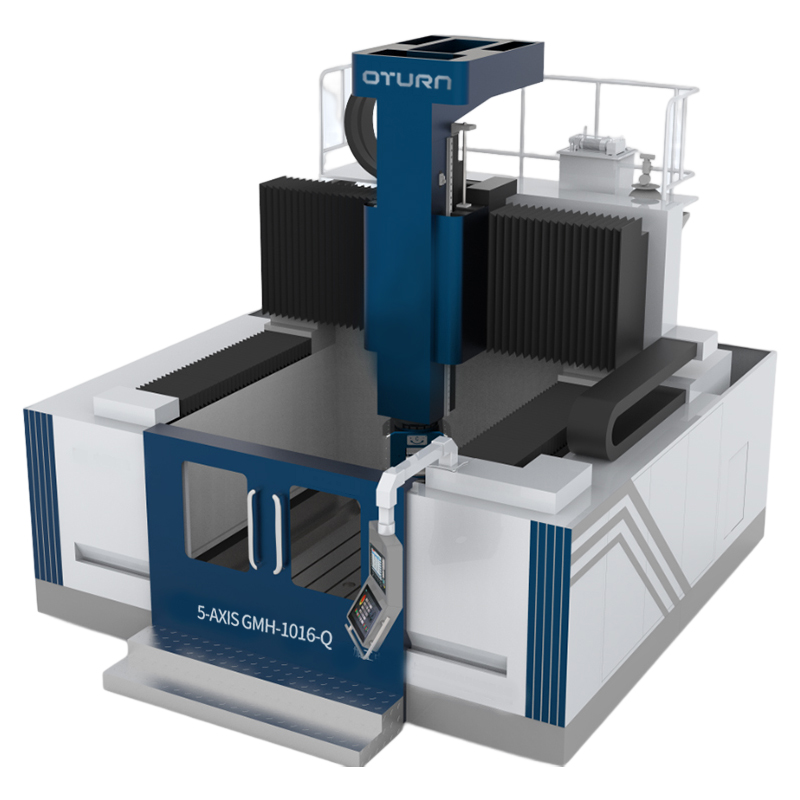

CNC Gantry Type Milling Machine from Leading China Manufacturer

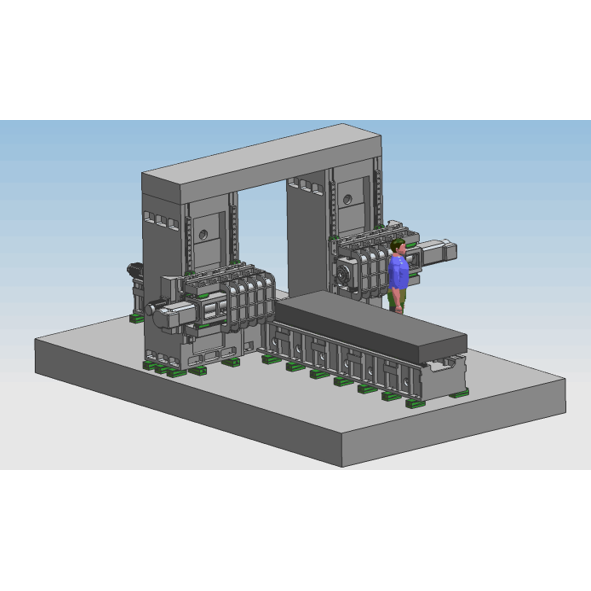

When it comes to precision and efficiency, a CNC Gantry Type Milling Machine is a game changer. I’ve seen firsthand how this powerful equipment transforms manufacturing processes. With its robust structure, it allows for increased stability and superior machining capabilities, making it ideal for a variety of applications. As a buyer, I appreciate sourcing machines from reliable manufacturers in China. The combination of advanced technology and skilled craftsmanship ensures durability and high performance. The CNC Gantry Type Milling Machine excels at handling large workpieces, enabling faster production times without compromising on quality. For B2B purchasers, this machine not only meets industry standards but also fits within budget constraints. If you’re ready to elevate your manufacturing capabilities, choosing a trusted Chinese manufacturer can make all the difference. Let’s unlock new levels of productivity with this cutting-edge solution.

Cnc Gantry Type Milling Machine Service Ahead of the Curve

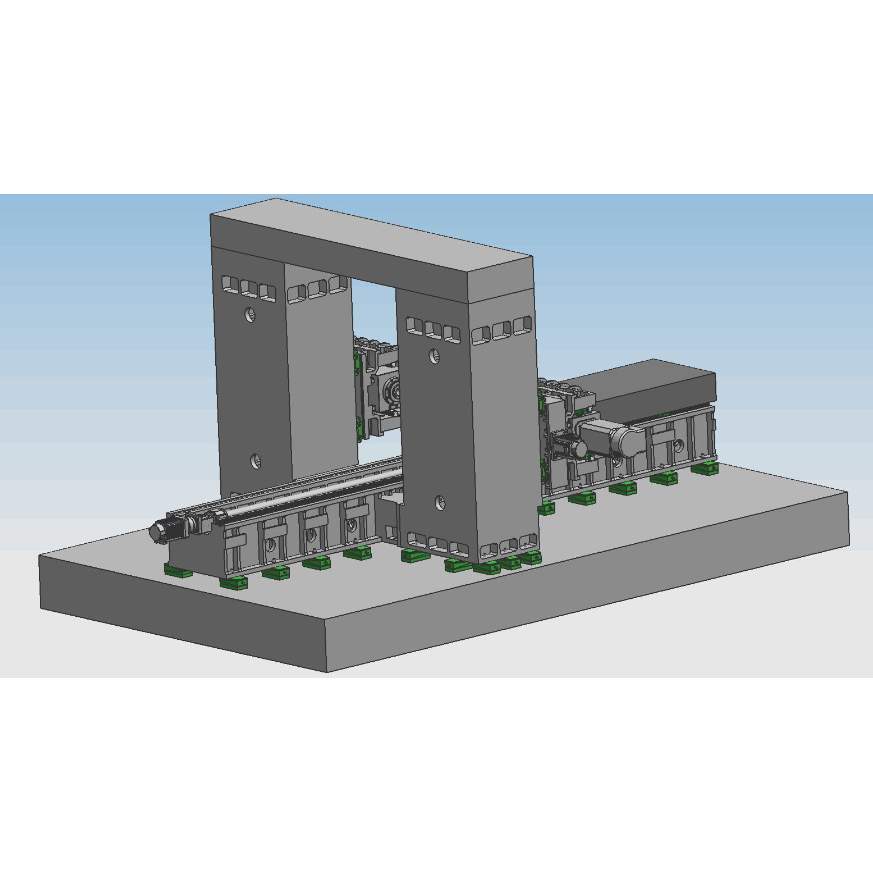

In today's competitive manufacturing landscape, staying ahead of the curve is essential for success. One of the most innovative solutions available is the CNC gantry type milling machine. Designed for precision and efficiency, these machines are perfect for various applications, from aerospace to automotive and beyond. Utilizing advanced technology, they offer greater flexibility and can handle complex tasks that traditional machining methods struggle with. The CNC gantry type milling machine is characterized by its robust construction and high stability, reducing the chances of errors during the machining process. With a large working envelope, it can accommodate sizeable workpieces and lower the overall machining time. This means businesses can boost productivity while ensuring high-quality output. Additionally, features like automatic tool changing and intuitive software make operation seamless, even for operators with limited experience. Investing in a CNC gantry type milling machine not only enhances operational capabilities but also positions businesses to adapt to future manufacturing demands. By embracing this cutting-edge technology, companies can optimize their processes, reduce costs, and improve overall competitiveness in the global marketplace.

Cnc Gantry Type Milling Machine Service Ahead of the Curve

| Feature | Specification | Application | Material Compatibility | Accuracy |

|---|---|---|---|---|

| Worktable Size | 1500 x 3000 mm | Large parts machining | Aluminum, Steel, Plastic | ±0.02 mm |

| Spindle Power | 15 kW | High-speed cutting | Titanium, Copper, Wood | ±0.01 mm |

| Feed Rate | 10 m/min | Complex shape machining | Composite materials | ±0.015 mm |

| Control System | CNC Controller | Automated operations | Alloy materials | ±0.005 mm |

| Weight | 3000 kg | Heavy-duty machining | Brass, Carbon steel | ±0.02 mm |

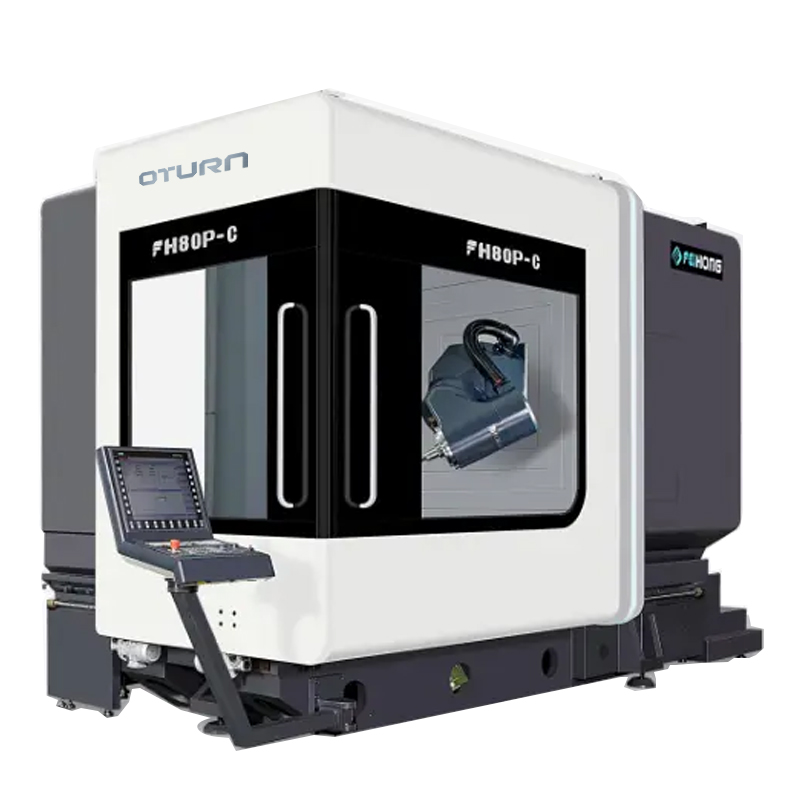

Related Products