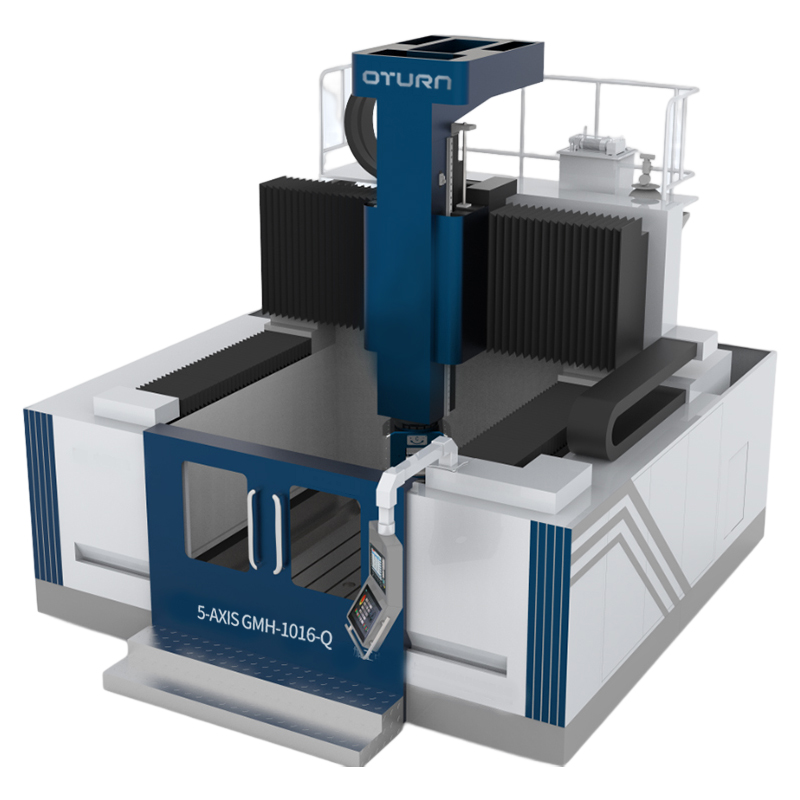

Vertical Turret Lathe Manufacturer in China | Quality Machinery Solutions

If you're in the market for a reliable Vertical Turret Lathe, I understand how crucial it is to find a manufacturer that meets your needs. I offer high-quality Vertical Turret Lathes from a trusted China manufacturer known for durability and precision. These machines are designed to handle various materials and complex tasks, making them a perfect fit for any machining environment. I believe that quality and efficiency are paramount. That’s why our Vertical Turret Lathes come equipped with advanced technology to enhance productivity. Whether you're a small business or a large manufacturing facility, these lathes can significantly improve your machining capabilities. With a strong reputation in the industry, my goal is to provide you with the best value for your investment. So if you’re seeking a robust Vertical Turret Lathe that stands the test of time, let’s connect and discuss how we can meet your requirements.

Vertical Turret Lathe Is The Best Where Innovation Meets 2025

In the fast-evolving world of manufacturing, the Vertical Turret Lathe stands out as a beacon of innovation and efficiency. Designed to meet the demands of modern industry, this machine tool is revolutionizing metalworking processes by marrying advanced technology with user-friendly operation. As businesses strive to enhance productivity and reduce downtime, the Vertical Turret Lathe offers flexibility and precision, making it ideal for various applications, from heavy-duty machining to intricate component fabrication. With its robust construction and advanced features, the Vertical Turret Lathe excels in delivering high performance and reliability. Manufacturers can significantly benefit from its capability to handle large workpieces while ensuring meticulous accuracy. Innovations in automation and control systems further enhance its appeal, allowing for streamlined operation and reduced manual intervention. As industries gear up for the challenges of 2025 and beyond, investing in this cutting-edge technology will empower companies to stay competitive in a global marketplace. Adopting the Vertical Turret Lathe is not just an upgrade; it's a strategic move towards sustainable and efficient manufacturing. By embracing innovation, businesses can achieve greater operational efficiency, minimize waste, and foster a culture of continuous improvement. As the manufacturing landscape continues to evolve, now is the perfect time to harness the power of the Vertical Turret Lathe and propel your operations into the future.

Vertical Turret Lathe Is The Best Where Innovation Meets 2025

| Feature | Description | Benefit |

|---|---|---|

| Precision | High accuracy in machining with advanced CNC technology. | Minimized material waste and improved product quality. |

| Versatility | Can machine various materials, including metals and plastics. | Wide application in different industries. |

| Automation | Incorporation of smart automation tools for increased efficiency. | Reduced labor costs and enhanced production speed. |

| Safety Features | Equipped with advanced safety measures to protect operators. | Ensures a safer working environment and compliance with regulations. |

| Cost-Effectiveness | Reduced maintenance and operational costs. | Increased overall profitability for manufacturing businesses. |

Related Products