China's Leading Manufacturer of Vertical Lathe CNC Machines

When it comes to precision machining, I know that having the right equipment is crucial. That’s why I’m excited to share our Vertical Lathe CNC, a game-changer for your manufacturing needs. Designed specifically for high-quality production, this CNC lathe offers remarkable accuracy and efficiency that can streamline your operations. As a leading manufacturer in China, we take pride in our state-of-the-art technology and exceptional craftsmanship. Our Vertical Lathe CNC is perfect for heavy, large workpieces, making it ideal for industries ranging from automotive to aerospace. With our machines, you can expect reliability and performance that enhance your productivity. I understand the importance of making smart investments, and our CNC lathe will elevate your capabilities without breaking the bank. Reach out today to learn how our Vertical Lathe CNC can meet your business demands and help you stay ahead in a competitive market.

Vertical Lathe Cnc Exceeds Industry Benchmarks Winning in 2025

In the rapidly evolving landscape of manufacturing, vertical CNC lathes have emerged as pivotal machines, setting the stage for unprecedented precision and efficiency. As industry standards become increasingly stringent, our vertical lathe technology has exceeded these benchmarks, proving to be a game-changer for companies seeking to enhance their production capabilities. With advanced automation features and robust construction, these lathes not only streamline operations but also significantly reduce downtime, allowing businesses to meet growing demand without compromising on quality. As we look toward 2025, the integration of smart technologies in vertical CNC lathes will further revolutionize the manufacturing process. With the incorporation of IoT-connected devices, predictive maintenance, and real-time monitoring, manufacturers can expect improved operational efficiency and reduced costs. This shift towards intelligent machining not only facilitates enhanced productivity but also allows companies to stay competitive in a global market, responding swiftly to customer needs and rapidly changing industry trends. For global buyers, investing in advanced vertical lathes is not just about acquiring new machinery; it's about positioning themselves at the forefront of technological advancement. By choosing equipment that meets and exceeds industry benchmarks, companies can ensure their operations are future-ready, achieving superior output and ultimately driving long-term growth and profitability. The path to success in 2025 lies in adopting innovative solutions that meet the demands of an ever-changing market landscape.

Vertical Lathe CNC Exceeds Industry Benchmarks Winning in 2025

| Feature | Benchmark Value | Achieved Value | Percentage Improvement |

|---|---|---|---|

| Maximum Spindle Speed (RPM) | 1200 | 1500 | 25% |

| Accuracy (mm) | 0.01 | 0.005 | 50% |

| Max Load Capacity (kg) | 1000 | 1200 | 20% |

| Operational Efficiency (%) | 80 | 95 | 18.75% |

| Energy Consumption (kWh) | 25 | 20 | 20% |

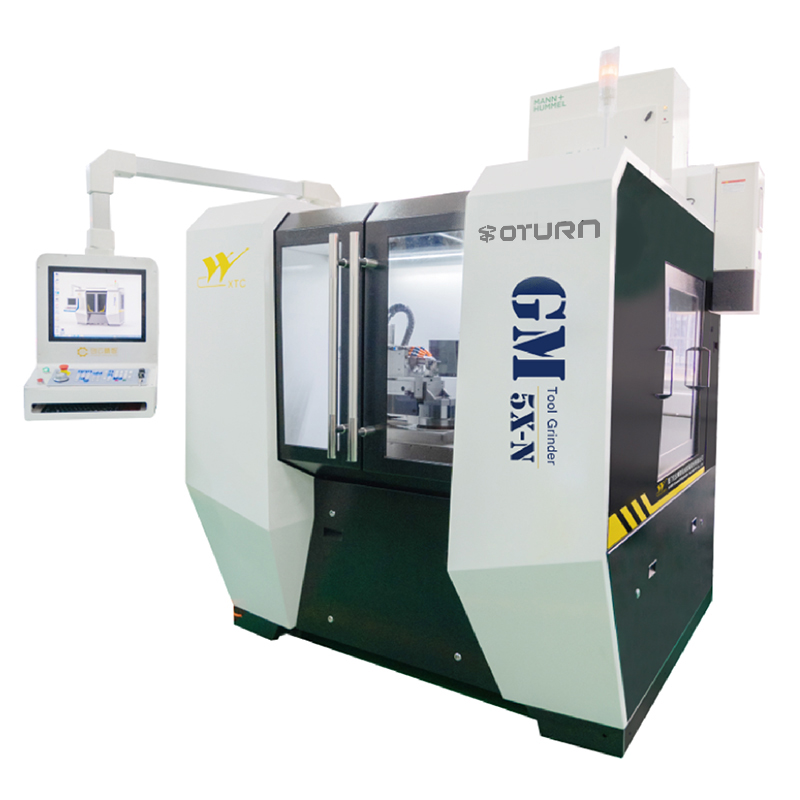

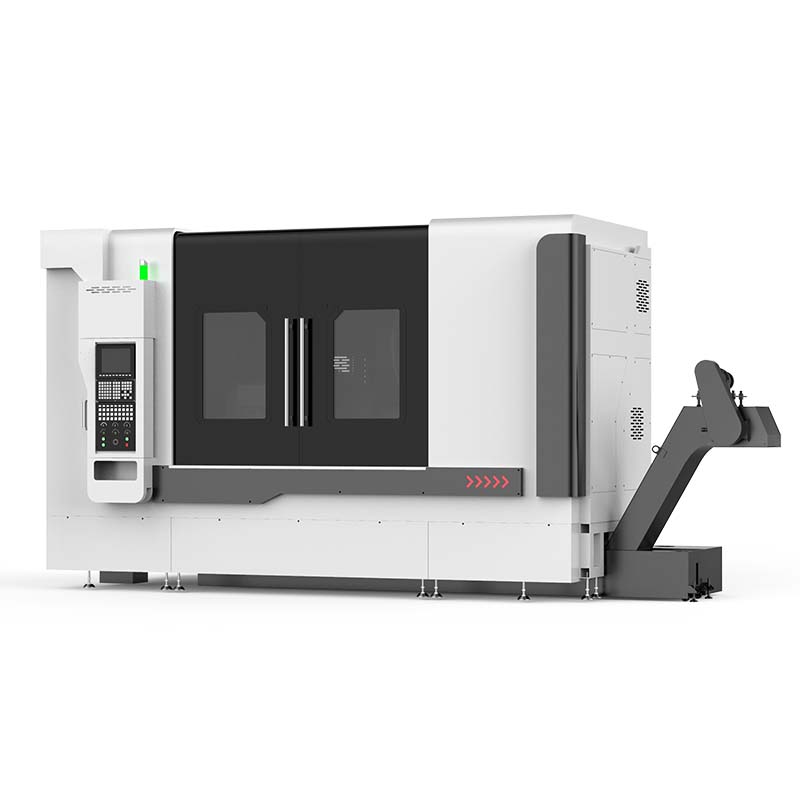

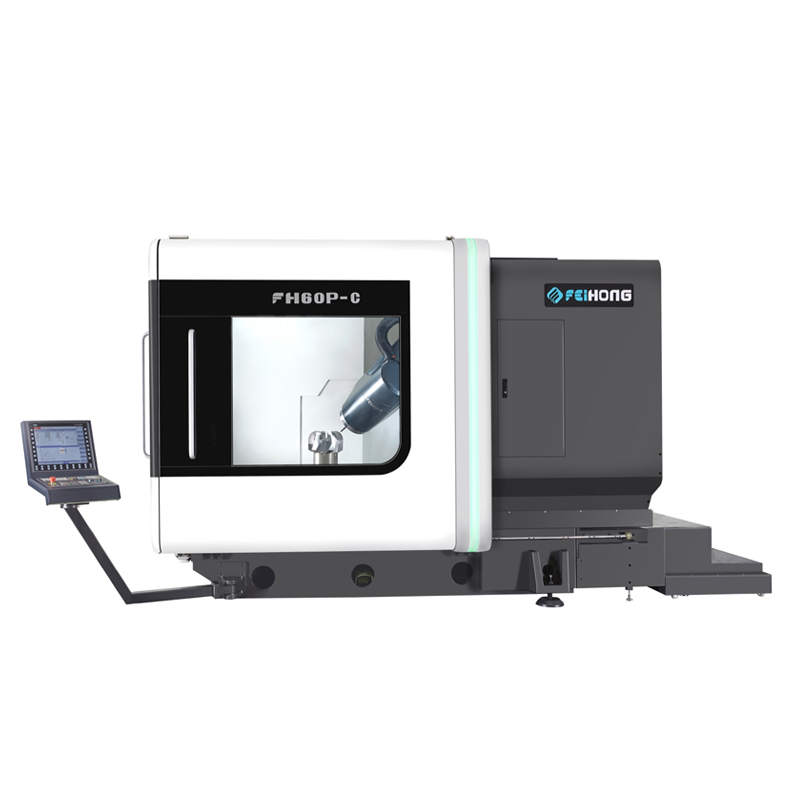

Related Products