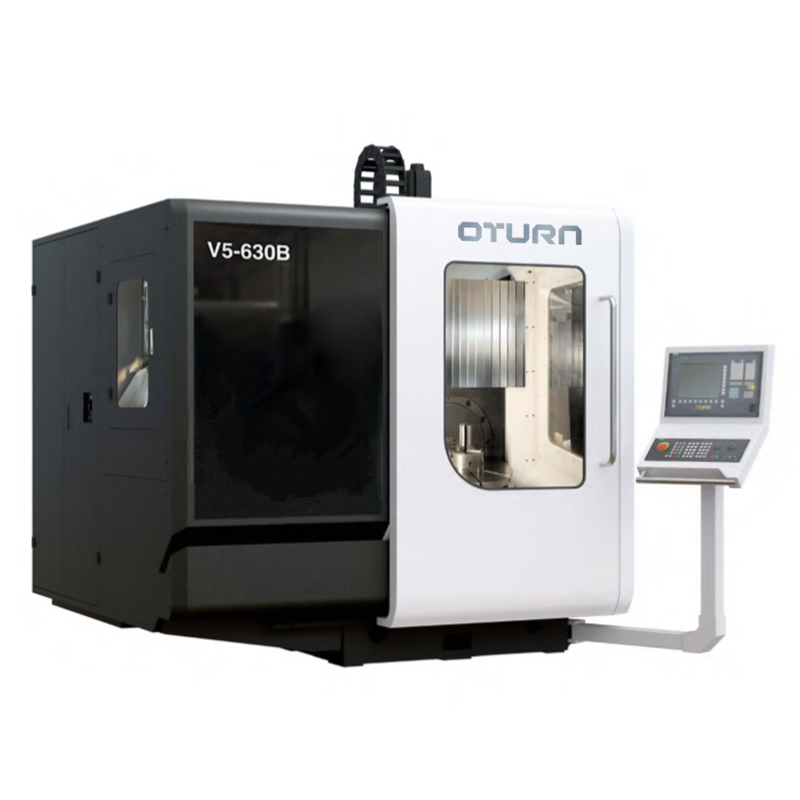

V5-630B Siemens 840D Five-axis Simultaneous

Five-Axis Vertical Machining Center

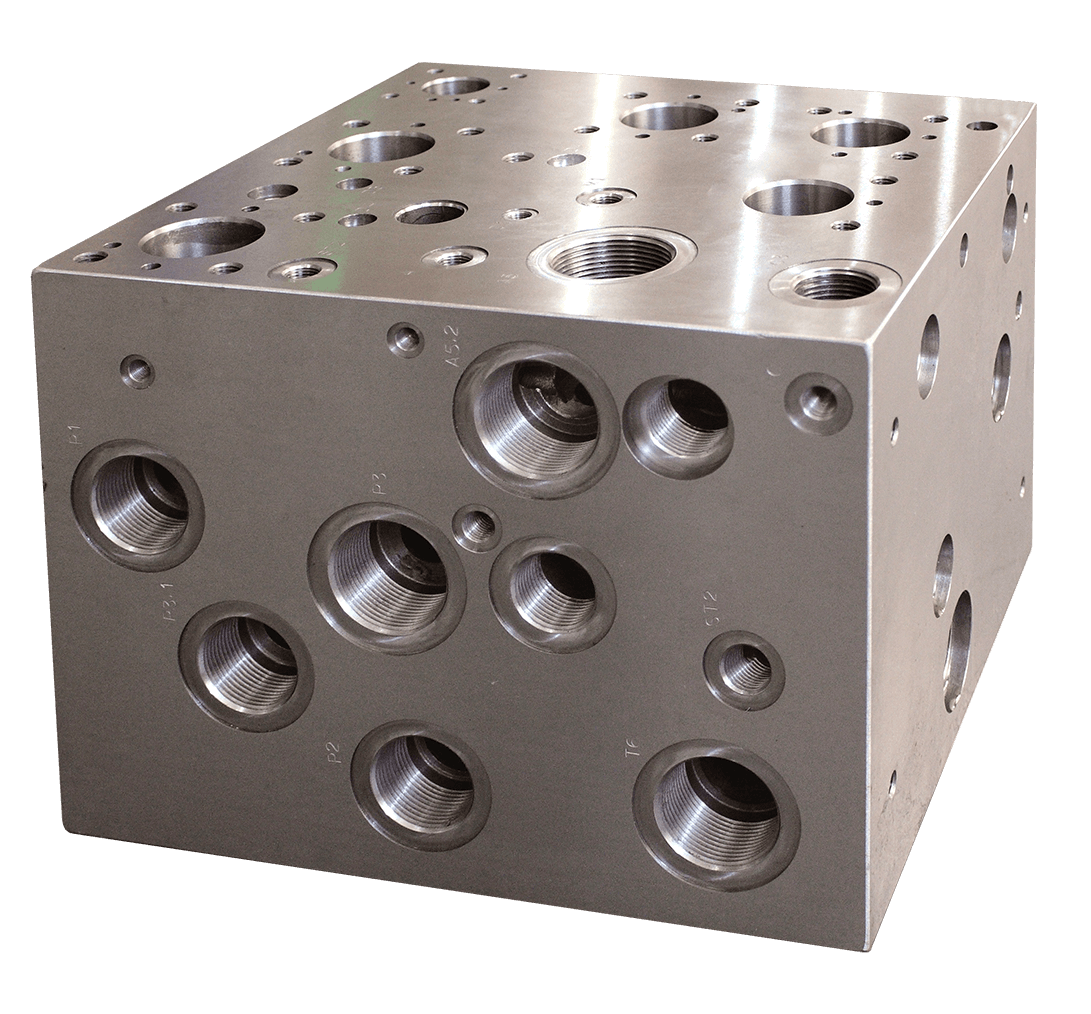

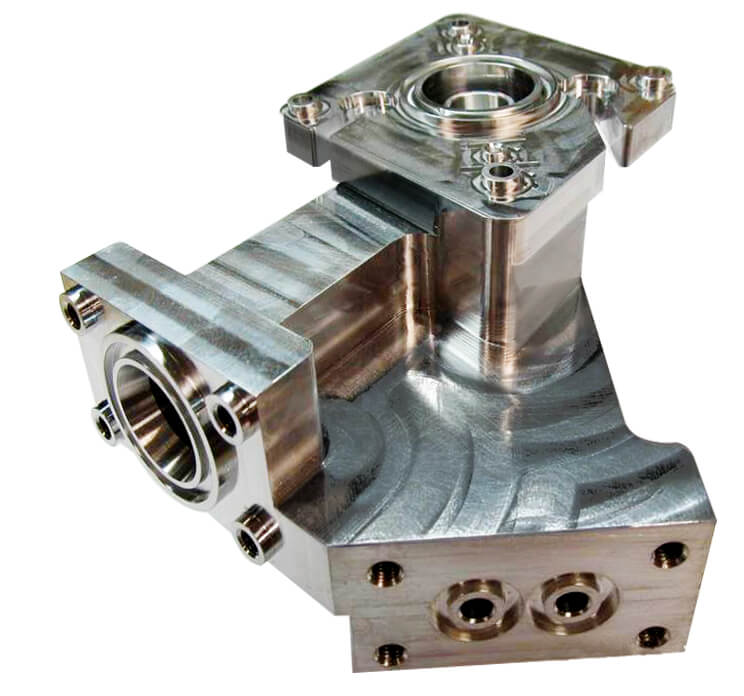

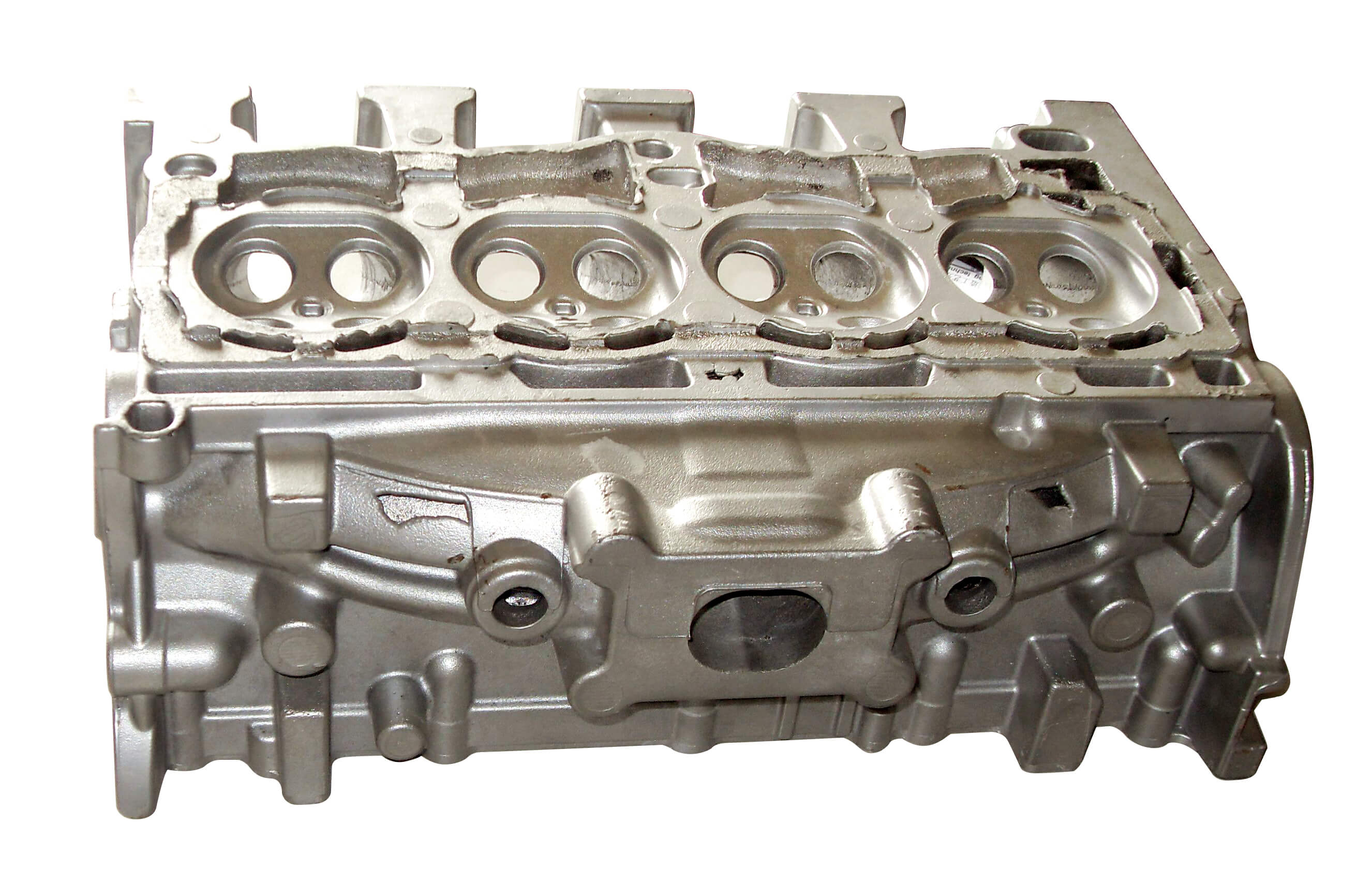

CTB self-developed five-axis vertical machining center, with stable C-shaped structure, standard high-speed motorized spindle, direct drive CNC turning-table and servo tool library, can achieve high-speed and high-precision processing of complex parts. It is widely used in the manufacture of electric vehicle motors, gearboxes,engines, moulds, robots, medical devices and other products.

CNC Controller: Siemens 840D

Main parameter

|

Item |

Unit |

Parameter |

|

|

Worktable |

worktable diameter |

mm |

φ630 |

|

Maximum horizontal load |

kg |

500 |

|

|

Maximum vertical load |

kg |

300 |

|

|

T-slot |

mm |

8X14H8 |

|

|

Processing range |

Distance between spindle end face and worktable end face (Max) |

mm |

550 |

|

Distance between spindle end face and worktable end face (Min) |

mm |

150 |

|

|

X axis |

mm |

600 |

|

|

Y axis |

mm |

450 |

|

|

Z axis |

mm |

400 |

|

|

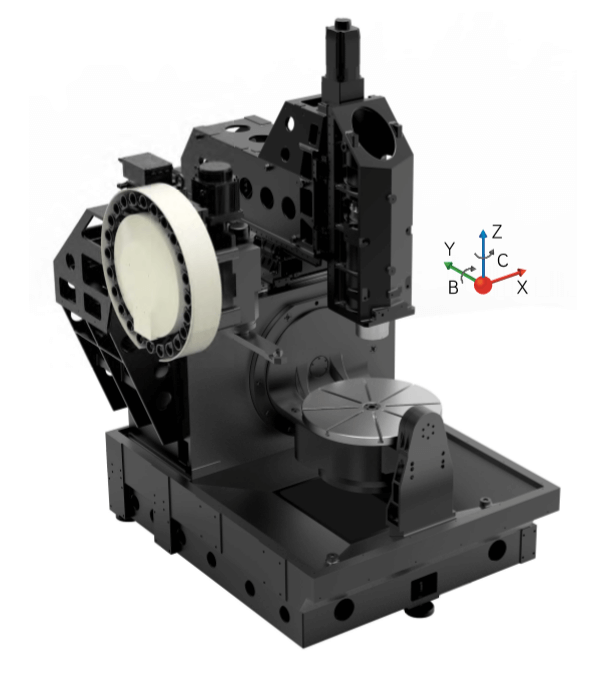

B axis |

° |

-35°~+110° |

|

|

C axis |

° |

nX360° |

|

|

Spindle |

Taper(7∶24) |

CTB |

BT40D |

|

Max. speed |

rpm |

12000 |

|

|

Rated torque S1 |

N.m |

69 |

|

|

Max. Torque S6 |

N.m |

98 |

|

|

Output power S1 |

kW |

13 |

|

|

Output power S6 |

kW |

18.5 |

|

|

Axis |

X axis Rapid traverse speed |

m/min |

36 |

|

Y axis Rapid traverse speed |

m/min |

36 |

|

|

Z axis Rapid traverse speed |

m/min |

36 |

|

|

B axis Max. speed |

rpm |

80 |

|

|

C axis Max. speed |

rpm |

80 |

|

|

Tool magazine |

Type |

|

Disc type |

|

Tool selection method |

|

Bidirectional nearest tool selection |

|

|

Capacity |

T |

24 |

|

|

Max. tool length |

mm |

300 |

|

|

Max. tool weight |

kg |

8 |

|

|

Max. cutter disc diameter(Full Tool) |

mm |

φ80 |

|

|

Maximum cutter disc diameter (Adjacent empty tool) |

mm |

φ120 |

|

|

Tool |

Tool holder type |

|

MAS403 BT40 |

|

Latin type |

|

MAS403 BT40-1 |

|

|

Accuracy |

Enforcement criteria |

|

GB/T20957.4(ISO10791-4) |

|

Positioning accuracy(X/Y/Z) |

mm |

0.008 |

|

|

positioning accuracy(B/C) |

|

8" |

|

|

Repeated positioning accuracy(X/Y/Z) |

mm |

0.006 |

|

|

|

Repeated positioning accuracy(B/C) |

|

6" |

|

Weight |

kg |

6000 |

|

|

Capacity |

KVA |

45 |

|

|

Overall dimension |

mm |

2400X3500X2850 |

|

|

Machine weight (N.W./ G.W.) |

Kg |

5500/6000 |

|

|

Package size |

mm |

3600X2500X2700 |

|

|

Machine installation space |

mm |

4000X4000X3000 |

|

Configuration List

Standard

|

No. |

Item |

Brand |

Configuration |

Remark |

|

1 |

CNC controller |

Siemens |

840D-710 |

X/Y/Z motor 1FK7063+5-axis machining package (M30) |

|

2 |

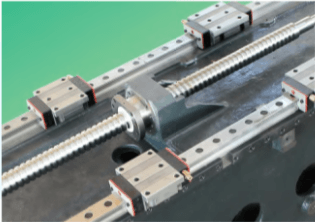

Guide rail |

Taiwan HIWIN |

35/35/35 |

|

|

3 |

Guide screw |

Taiwan HIWIN |

38/38/31 |

|

|

4 |

Spindle |

CTB |

BT40 |

|

|

5 |

Turning-table |

CTB |

BC630 |

Renishaw encoder |

|

6 |

Tool magazine |

Poju |

BT40-24T |

|

|

7 |

Hydraulic unit |

CTB |

1P1V3-4 |

|

|

8 |

Lubrication System |

Vale S.A. |

GM-3204-2 |

|

|

9 |

Pneumatic system |

Japan SMC |

complete set |

|

|

10 |

Water cooler |

Baoji Labo |

LW-25PT |

|

|

11 |

Electric Cabinet Air Conditioner |

Baoji Labo |

LA-08WB |

|

|

12 |

Chip conveyor water tank |

BF |

|

|

|

13 |

Energy chain |

German Igus |

complete set |

|

|

14 |

Screw bearing |

Japan NACHI/NSK |

complete set |

|

|

15 |

Coupling |

Japan NBK |

MJC-55CS |

|

|

16 |

Guide rail |

Qingdao Heima Zhao |

|

|

|

17 |

Machine protective cover |

Hebei or handong |

|

|

Options

|

No. |

Item |

Brand |

Configuration |

Remark |

|

1 |

Hydraulic station |

Germany Hydraulic |

1P1V3-4-H |

|

|

2 |

Turntable |

CTB |

BC630 |

HEIDENHAIN encoders |

|

3 |

Raster scale |

Spain FAGOR |

S2AS |

|

|

4 |

Motorized spindle |

CTB |

HSKA63 |

Including motorized |

|

5 |

Central cooling device |

CTB |

Complete set |

Including rotary joint, internal cold water tank, high pressure pump, etc. |

|

6 |

Tool measuring system |

Renishaw |

RTS |

Measurement set |

|

7 |

Workpiece measuring system |

Renishaw |

RMP40 |

|

|

8 |

Rotary axis Line inspection tool |

Renishaw |

Axiset |

|

|

9 |

Tool measuring system |

Renishaw |

OTS |

Measurement set |

|

10 |

Workpiece measuring system |

Renishaw |

OMP40 |

|

|

11 |

Power-off fallback function |

Siemens |

UPS package |

Protect tools, workpieces and fixtures |

|

12 |

Fully enclosed protective cover |

CTB |

|

Including automatic pneumatic sunroof |

|

13 |

Post-processing software |

CTB |

Based on UG software |

Thanks For Your Attention!