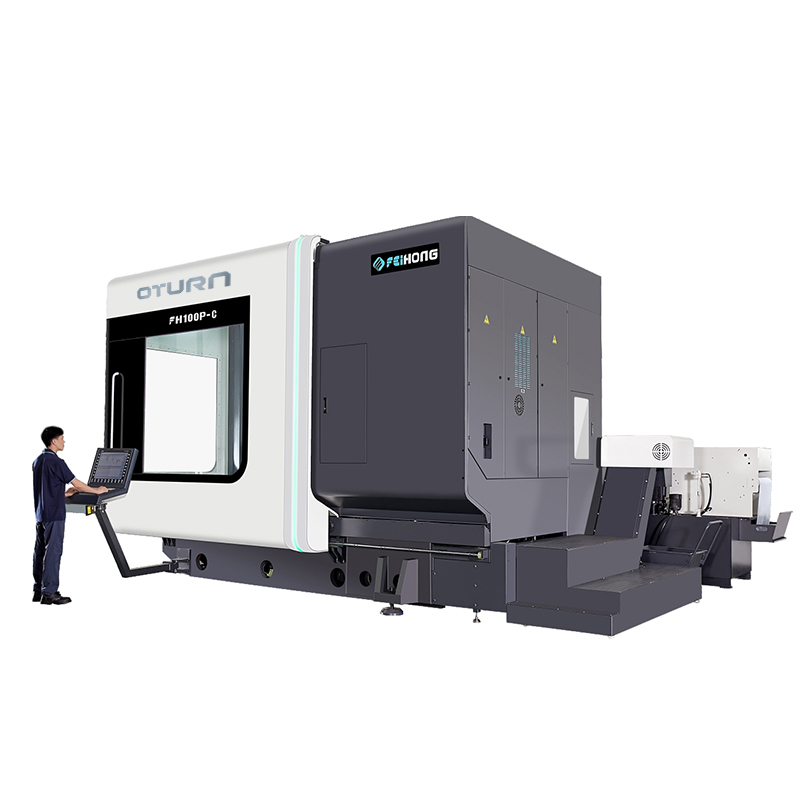

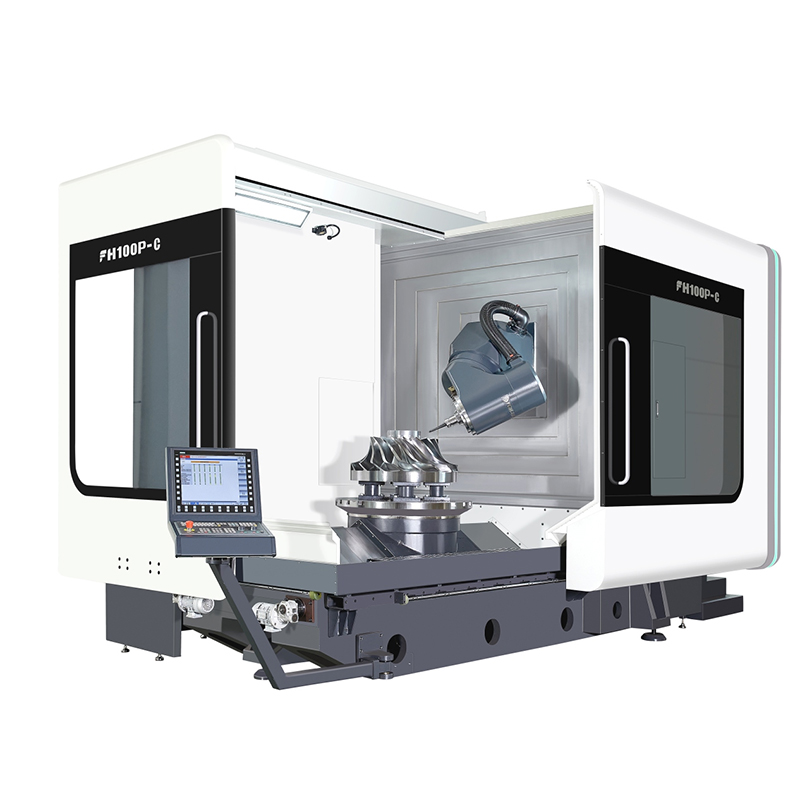

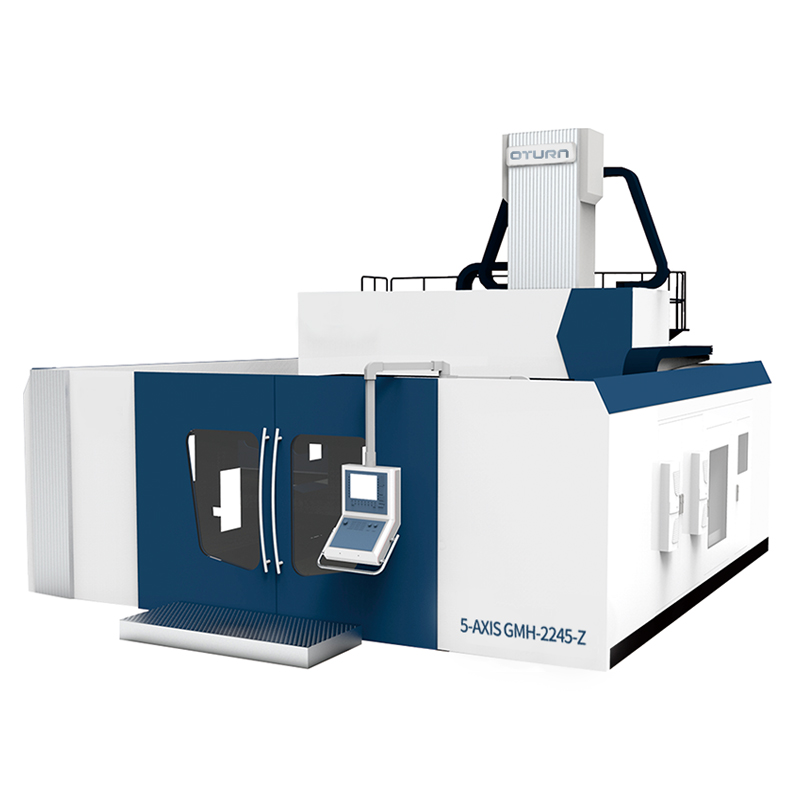

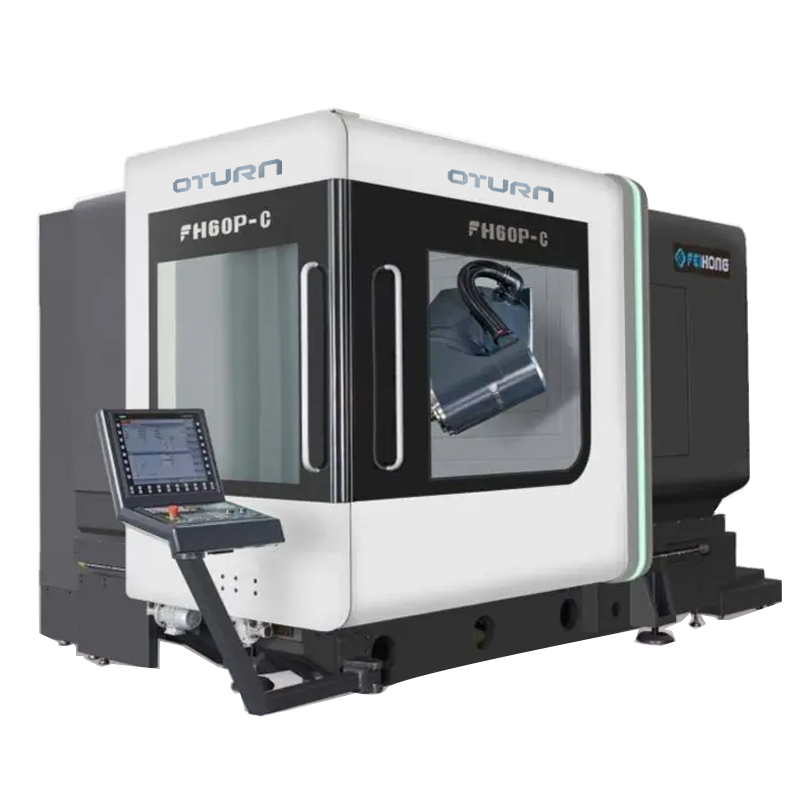

Top Turning Centers from Leading Manufacturers in China

Are you in the market for reliable turning centers? As a manufacturer based in China, we specialize in providing top-notch turning centers that cater to diverse industrial needs. Our machines are engineered for precision and efficiency, helping you achieve optimal results in your production line. I know that choosing the right equipment can be challenging, especially with so many options available. That's why our turning centers are designed with the latest technology to ensure durability and performance. Whether you need to handle small or large scale operations, our machines are adaptable to your requirements. By opting for our turning centers, you’re not just investing in quality; you’re also gaining a partner committed to your success. Let’s work together to elevate your manufacturing capabilities! Reach out today to learn more about how our turning centers can meet your specific needs.

Turning Centers Ahead of the Curve More Than a Supplier - A Partner

In the rapidly evolving world of manufacturing, businesses are constantly seeking reliable partners that can provide innovative solutions and support their growth. Turning centers play a pivotal role in this landscape, serving not just as suppliers but as strategic partners capable of advancing operations. By leveraging advanced technology and expertise, they can offer tailored solutions that align with the specific needs of their clients, empowering them to stay ahead of market trends. A forward-thinking turning center understands the importance of collaboration and open communication. This relationship fosters an environment where both parties can share insights and strategies, leading to more efficient processes and enhanced product development. With a focus on quality, precision, and timely delivery, these partners can help businesses optimize their supply chains and reduce operational risks, ensuring that they remain competitive in a global marketplace. Moreover, the integration of cutting-edge technology, such as automation and IoT, into turning centers further enhances their capability to meet diverse demands. By investing in research and development, they continuously improve their offerings, making it possible for businesses to adapt to changing market dynamics swiftly. Ultimately, partnering with a proactive turning center equips global buyers with the tools and support needed to navigate the complexities of modern manufacturing successfully.

Turning Centers Ahead of the Curve More Than a Supplier - A Partner

| Partner Type | Expertise | Service Offered | Technology Utilized | Industry Focus |

|---|---|---|---|---|

| Strategic Partner | Manufacturing Processes | Process Optimization | CNC Machining | Aerospace |

| Technical Advisor | Tooling Solutions | Tool Selection | 3D Printing | Automotive |

| Logistics Partner | Supply Chain Management | Inventory Solutions | ERP Systems | Electronics |

| Innovation Partner | R&D Capabilities | Product Development | IoT Integration | Consumer Goods |

| Quality Assurance Partner | Quality Control | Testing Services | Automation Solutions | Pharmaceutical |

Related Products