Turning Center TMC Series

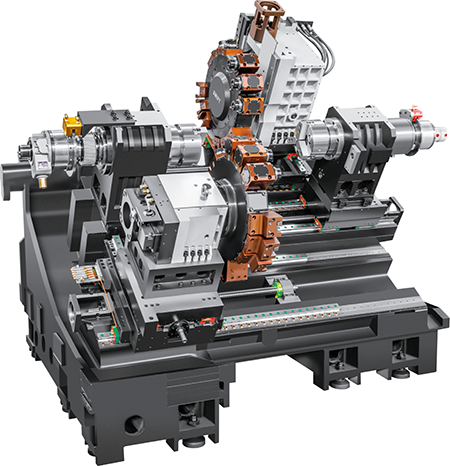

Product Configuration

Machine features

High rigidity, heavy cutting, high stability: integrated cast slant bed, flatbed, 45° inclined rail, and thick rib design to minimize distortion andthermal deformation.

High-precision, high dynamic response: High-precision NSK P4 ballbearings are used in front and rear to achieve high rigidity and highspindle rotation accuracy, The spindle servo unit has high precision andconvenient maintenance.

High efficiency: The maximum speed of the main shaft is 6000rpm/min,and the rapid movement can reach 24m/min. Through the configurationof Taiwan's new generation CNC system, X-C axis linkage interpolation isrealized, and the virtual Y axis function is realized.

Technical Specifications

|

Project |

CNC-460TMC |

CNC-520TMC |

CNC-680TMC |

CNC-860TMC(1000) |

CNC-860TMC(1500) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is slanted at 40°. |

The bed and base are made of high-quality cast iron. 30° inclined bed |

The bed and base are made of high-quality cast iron. 45 inclined bed |

|||

|

Processing Range |

Max. swing diameter over bed |

540mm |

600mm |

600mm |

780mm |

780mm |

| Max. processing diameter of discs |

360mm |

320mm |

400mm |

650mm |

650mm |

|

| Max. processing diameter of the carriage |

280mm |

320mm |

400mm |

500mm |

500mm |

|

| Max. processing length of bar |

400mm |

480mm |

680mm |

900mm |

1400mm |

|

| Max. bar diameter |

ф45mm |

ф51mm |

ф51mm |

ф75mm |

ф75mm |

|

|

Travel Feed |

Max. X-axis travel |

220mm |

220mm |

230mm |

350mm |

350mm |

| Max. Z-axis travel |

470mm |

520mm |

750mm |

1050mm |

1550mm |

|

| Max. Y-axis travel |

±35mm |

±45mm |

±45mm |

±75mm |

±75mm |

|

| X/Z/Y axis rapid speed |

30m/min |

30m/min |

30m/min |

16m/min |

16m/min |

|

| X/Z/Y screw diameter/pitch |

32/10mm |

X:40/10mm |

40/10mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

35mm |

45mm |

35mm |

55mm |

55mm |

|

| X-axis servo motor |

β12(Brake) |

β12(Brake) |

β12(Brake) |

β22(Brake) |

β22(Brake) |

|

| Z-axis servo motor |

β12 |

β12 |

β12 |

β22 |

β22 |

|

| Y-axis servo motor |

β8(Brake) |

β12(Brake) |

β12(Brake) |

β22 |

β22 |

|

| Servo turret motor |

3N.m |

3N.m |

3N.m |

1KW |

1KW |

|

| Power head motor |

β12 |

β12 |

β12 |

β22 |

β22 |

|

|

Accuracy |

X/Z axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock travel |

40-460mm |

50-600mm |

0-790mm |

ф150/200mm |

ф150/200mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

Programmable hydraulic |

Programmable hydraulic |

Saddle driven, |

(Hardway) Hydraulic driven |

||

|

Spindle |

Spindle taper |

A2-5 |

A2-6 |

A2-6 |

A2-8 |

A2-8 |

| Spindle bore diameter |

ф56mm |

ф66mm |

ф66mm |

ф88mm |

ф88mm |

|

| Max. Spindle speed |

6000rpm |

4500rpm |

4500rpm |

2500rpm |

2500rpm |

|

| Spindle motor power |

7.5/11KW |

11KW |

11/15KW |

15KW |

15KW |

|

| Servo powered turret |

BMT40/12 Stations |

BMT55/12 Stations |

BMT55/12 Stations |

BMT65/12 Stations |

BMT65/12 Stations |

|

|

Turret |

Tool disc size |

240 |

330 |

330 |

380 |

380(hard rail) |

| Tool holder specifications |

□20×20 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

|

| Boring tool holder |

ф25mm |

ф32mm |

ф32mm |

ф40mm |

ф40mm |

|

| 0 degree side milling head (1 station) |

ER20/3000rpm |

ER32/3000rpm |

ER32/3000rpm |

ER40/3000rpm |

ER40/3000rpm |

|

| 90 degree side milling head (1 station) |

ER20/3000rpm |

ER32/3000rpm |

ER32/3000rpm |

ER40/3000rpm |

ER40/3000rpm |

|

|

Other |

Total capacitance |

22KW |

26KW |

26KW |

34KW |

34KW |

| Machine tool net weight |

About 3800Kg |

About 4000Kg |

About 5000Kg |

About 7000Kg |

About 7800Kg |

|

| Machine size (length × width × height) |

2600×1700×1950 |

2800×1700×2000 |

2900×2000×2200 |

6000×2300×2550 |

6500×2300×2550 |

|

|

Project |

CNC-860TMC(2000) |

CNC-860TMC(3000) |

CNC-960TMC(1000) |

CNC-960TMC(1500) |

CNC-960TMC(2000) |

CNC-960TMC(3000) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is 45° inclined. |

The bed and base are made of high-quality cast iron, and the bed is slanted at 45°. |

|||||

|

Processing Range |

Max. swing diameter over bed |

780mm |

780mm |

880mm |

880mm |

880mm |

880mm |

| Max. processing diameter of discs |

650mm |

650mm |

650mm |

650mm |

650mm |

650mm |

|

| Max. processing diameter of the carriage |

500mm |

500mm |

600mm |

600mm |

600mm |

600mm |

|

| Max. processing length of bar |

1900mm |

2900mm |

900mm |

1400mm |

1900mm |

2900mm |

|

| Max. bar diameter |

ф75mm |

ф75mm |

ф91mm |

ф91mm |

ф91mm |

ф91mm |

|

|

Travel Feed |

Max. X-axis travel |

350mm |

350mm |

350mm |

350mm |

350mm |

350mm |

| Max. Z-axis travel |

2050mm |

3050mm |

1050mm |

1550mm |

2050mm |

3050mm |

|

| Max. Y-axis travel |

±75mm |

±75mm |

±75mm |

±75mm |

±75mm |

±75mm |

|

| X/Z/Y axis rapid speed |

16m/min |

16m/min |

16m/min |

16m/min |

16m/min |

16m/min |

|

| X/Z/Y screw diameter/pitch |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

55mm |

55mm |

55mm |

55mm |

55mm |

55mm |

|

| X-axis servo motor |

β22(Brake) |

β22(Brake) |

β22(Brake) |

β22(Brake) |

α22(Brake) |

α22(Brake) |

|

| Z-axis servo motor |

β22 |

β22 |

β12(Brake) |

β12(Brake) |

α12(Brake) |

α12(Brake) |

|

| Y-axis servo motor |

β22 |

β22 |

β22 |

β22 |

β22 |

β22 |

|

| Servo turret motor |

1KW |

1KW |

1KW |

1KW |

1KW |

1KW |

|

| Power head motor |

β22 |

β22 |

β22 |

β22 |

β22 |

β22 |

|

|

Accuracy |

X/Z axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock travel |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

(Hardway)Hydraulic driven |

(Hardway)Hydraulic driven |

|||||

|

Spindle |

Spindle taper |

A2-8 |

A2-8 |

A2-11 |

A2-11 |

A2-11 |

A2-11 |

| Spindle bore diameter |

ф88mm |

ф88mm |

ф105mm |

ф105mm |

ф105mm |

ф105mm |

|

| Max. Spindle speed |

2500rpm |

2500rpm |

2200rpm |

2200rpm |

2200rpm |

2200rpm |

|

| Spindle motor power |

22KW |

30KW |

15KW |

15KW |

22KW |

30KW |

|

| Servo powered turret |

BMT65/12 Stations |

BMT65/12 Stations |

BMT65/12Stations |

BMT65/12 Stations |

BMT65/12 Stations |

BMT65/12 Stations |

|

|

Turret |

Tool disc size |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

| Tool holder specifications |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

|

| Boring tool holder |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

|

| 0 degree side milling head (1 station) |

ER40/4000rpm |

ER40/4000rpm |

ER40/3000rpm |

ER40/3000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

| 90 degree side milling head (1 station) |

ER40/4000rpm |

ER40/4000rpm |

ER40/3000rpm |

ER40/3000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

|

Other |

Total capacitance |

48KW |

55KW |

34KW |

34KW |

48KW |

55KW |

| Machine tool net weight |

About 9000Kg |

About 11500Kg |

About 7000Kg |

About 7800Kg |

About 9000Kg |

About 11500Kg |

|

| Machine size (length × width × height) |

7000×2300×2550 |

8500×2300×2550 |

6000×2300×2550 |

6500×2300×2550 |

7000×2300×2550 |

8500×2300×2550 |

|

Configuration Features

Spindle

Support high-precision and heavy-duty cutting to increase productivity.

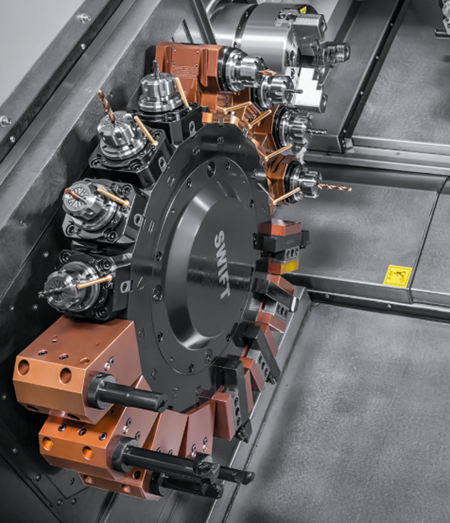

Turret

Improves indexing reliability and ensures high rigidity.

System

Standard FANUC F Oi-TF Plus CNC System, high processing performance high operating rate, high ease of use.

High Rigidity

Heavy-duty Cast Iron Base And Components, Strong shock absorption and high stability.

Ball Screw

Screw pretensioning, backlash andtemperature rise elongation areeliminated in advance.

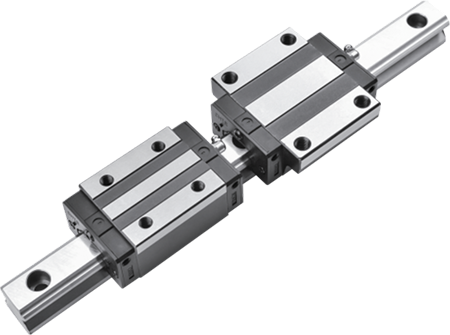

Roller Linear Guide

Arc cutting, bevel cutting, and uniform surface texture. Universal high-speed rotation.

High rigidity, heavy cutting, high stability: integrated cast slant bed, flatbed, 45° inclined rail, and thick rib design to minimize distortion andthermal deformation.

High-precision, high dynamic response: High-precision NSK P4 ballbearings are used in front and rear to achieve high rigidity and highspindle rotation accuracy, The spindle servo unit has high precision andconvenient maintenance.

High efficiency: The maximum speed of the main shaft is 6000rpm/min,and the rapid movement can reach 24m/min. Through the configurationof Taiwan’s new generation CNC system, X-C axis linkage interpolation isrealized, and the virtual Y axis function is realized.

|

Project |

CNC-460TMC |

CNC-520TMC |

CNC-680TMC |

CNC-860TMC(1000) |

CNC-860TMC(1500) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is slanted at 40°. |

The bed and base are made of high-quality cast iron. 30° inclined bed |

The bed and base are made of high-quality cast iron. 45 inclined bed |

|||

|

Processing Range |

Max. swing diameter over bed |

540mm |

600mm |

600mm |

780mm |

780mm |

| Max. processing diameter of discs |

360mm |

320mm |

400mm |

650mm |

650mm |

|

| Max. processing diameter of the carriage |

280mm |

320mm |

400mm |

500mm |

500mm |

|

| Max. processing length of bar |

400mm |

480mm |

680mm |

900mm |

1400mm |

|

| Max. bar diameter |

ф45mm |

ф51mm |

ф51mm |

ф75mm |

ф75mm |

|

|

Travel Feed |

Max. X-axis travel |

220mm |

220mm |

230mm |

350mm |

350mm |

| Max. Z-axis travel |

470mm |

520mm |

750mm |

1050mm |

1550mm |

|

| Max. Y-axis travel |

±35mm |

±45mm |

±45mm |

±75mm |

±75mm |

|

| X/Z/Y axis rapid speed |

30m/min |

30m/min |

30m/min |

16m/min |

16m/min |

|

| X/Z/Y screw diameter/pitch |

32/10mm |

X:40/10mm |

40/10mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

35mm |

45mm |

35mm |

55mm |

55mm |

|

| X-axis servo motor |

β12(Brake) |

β12(Brake) |

β12(Brake) |

β22(Brake) |

β22(Brake) |

|

| Z-axis servo motor |

β12 |

β12 |

β12 |

β22 |

β22 |

|

| Y-axis servo motor |

β8(Brake) |

β12(Brake) |

β12(Brake) |

β22 |

β22 |

|

| Servo turret motor |

3N.m |

3N.m |

3N.m |

1KW |

1KW |

|

| Power head motor |

β12 |

β12 |

β12 |

β22 |

β22 |

|

|

Accuracy |

X/Z axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock travel |

40-460mm |

50-600mm |

0-790mm |

ф150/200mm |

ф150/200mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

Programmable hydraulic |

Programmable hydraulic |

Saddle driven, |

(Hardway) Hydraulic driven |

||

|

Spindle |

Spindle taper |

A2-5 |

A2-6 |

A2-6 |

A2-8 |

A2-8 |

| Spindle bore diameter |

ф56mm |

ф66mm |

ф66mm |

ф88mm |

ф88mm |

|

| Max. Spindle speed |

6000rpm |

4500rpm |

4500rpm |

2500rpm |

2500rpm |

|

| Spindle motor power |

7.5/11KW |

11KW |

11/15KW |

15KW |

15KW |

|

| Servo powered turret |

BMT40/12 Stations |

BMT55/12 Stations |

BMT55/12 Stations |

BMT65/12 Stations |

BMT65/12 Stations |

|

|

Turret |

Tool disc size |

240 |

330 |

330 |

380 |

380(hard rail) |

| Tool holder specifications |

□20×20 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

|

| Boring tool holder |

ф25mm |

ф32mm |

ф32mm |

ф40mm |

ф40mm |

|

| 0 degree side milling head (1 station) |

ER20/3000rpm |

ER32/3000rpm |

ER32/3000rpm |

ER40/3000rpm |

ER40/3000rpm |

|

| 90 degree side milling head (1 station) |

ER20/3000rpm |

ER32/3000rpm |

ER32/3000rpm |

ER40/3000rpm |

ER40/3000rpm |

|

|

Other |

Total capacitance |

22KW |

26KW |

26KW |

34KW |

34KW |

| Machine tool net weight |

About 3800Kg |

About 4000Kg |

About 5000Kg |

About 7000Kg |

About 7800Kg |

|

| Machine size (length × width × height) |

2600×1700×1950 |

2800×1700×2000 |

2900×2000×2200 |

6000×2300×2550 |

6500×2300×2550 |

|

|

Project |

CNC-860TMC(2000) |

CNC-860TMC(3000) |

CNC-960TMC(1000) |

CNC-960TMC(1500) |

CNC-960TMC(2000) |

CNC-960TMC(3000) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is 45° inclined. |

The bed and base are made of high-quality cast iron, and the bed is slanted at 45°. |

|||||

|

Processing Range |

Max. swing diameter over bed |

780mm |

780mm |

880mm |

880mm |

880mm |

880mm |

| Max. processing diameter of discs |

650mm |

650mm |

650mm |

650mm |

650mm |

650mm |

|

| Max. processing diameter of the carriage |

500mm |

500mm |

600mm |

600mm |

600mm |

600mm |

|

| Max. processing length of bar |

1900mm |

2900mm |

900mm |

1400mm |

1900mm |

2900mm |

|

| Max. bar diameter |

ф75mm |

ф75mm |

ф91mm |

ф91mm |

ф91mm |

ф91mm |

|

|

Travel Feed |

Max. X-axis travel |

350mm |

350mm |

350mm |

350mm |

350mm |

350mm |

| Max. Z-axis travel |

2050mm |

3050mm |

1050mm |

1550mm |

2050mm |

3050mm |

|

| Max. Y-axis travel |

±75mm |

±75mm |

±75mm |

±75mm |

±75mm |

±75mm |

|

| X/Z/Y axis rapid speed |

16m/min |

16m/min |

16m/min |

16m/min |

16m/min |

16m/min |

|

| X/Z/Y screw diameter/pitch |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

55mm |

55mm |

55mm |

55mm |

55mm |

55mm |

|

| X-axis servo motor |

β22(Brake) |

β22(Brake) |

β22(Brake) |

β22(Brake) |

α22(Brake) |

α22(Brake) |

|

| Z-axis servo motor |

β22 |

β22 |

β12(Brake) |

β12(Brake) |

α12(Brake) |

α12(Brake) |

|

| Y-axis servo motor |

β22 |

β22 |

β22 |

β22 |

β22 |

β22 |

|

| Servo turret motor |

1KW |

1KW |

1KW |

1KW |

1KW |

1KW |

|

| Power head motor |

β22 |

β22 |

β22 |

β22 |

β22 |

β22 |

|

|

Accuracy |

X/Z axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock travel |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

ф150/200mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

(Hardway)Hydraulic driven |

(Hardway)Hydraulic driven |

|||||

|

Spindle |

Spindle taper |

A2-8 |

A2-8 |

A2-11 |

A2-11 |

A2-11 |

A2-11 |

| Spindle bore diameter |

ф88mm |

ф88mm |

ф105mm |

ф105mm |

ф105mm |

ф105mm |

|

| Max. Spindle speed |

2500rpm |

2500rpm |

2200rpm |

2200rpm |

2200rpm |

2200rpm |

|

| Spindle motor power |

22KW |

30KW |

15KW |

15KW |

22KW |

30KW |

|

| Servo powered turret |

BMT65/12 Stations |

BMT65/12 Stations |

BMT65/12Stations |

BMT65/12 Stations |

BMT65/12 Stations |

BMT65/12 Stations |

|

|

Turret |

Tool disc size |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

380(hard rail) |

| Tool holder specifications |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

|

| Boring tool holder |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

|

| 0 degree side milling head (1 station) |

ER40/4000rpm |

ER40/4000rpm |

ER40/3000rpm |

ER40/3000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

| 90 degree side milling head (1 station) |

ER40/4000rpm |

ER40/4000rpm |

ER40/3000rpm |

ER40/3000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

|

Other |

Total capacitance |

48KW |

55KW |

34KW |

34KW |

48KW |

55KW |

| Machine tool net weight |

About 9000Kg |

About 11500Kg |

About 7000Kg |

About 7800Kg |

About 9000Kg |

About 11500Kg |

|

| Machine size (length × width × height) |

7000×2300×2550 |

8500×2300×2550 |

6000×2300×2550 |

6500×2300×2550 |

7000×2300×2550 |

8500×2300×2550 |

|