Top Quality Cnc Horizontal Milling Machine - Soft Gate Valve Production Line – Oturn

Top Quality Cnc Horizontal Milling Machine - Soft Gate Valve Production Line – Oturn Detail:

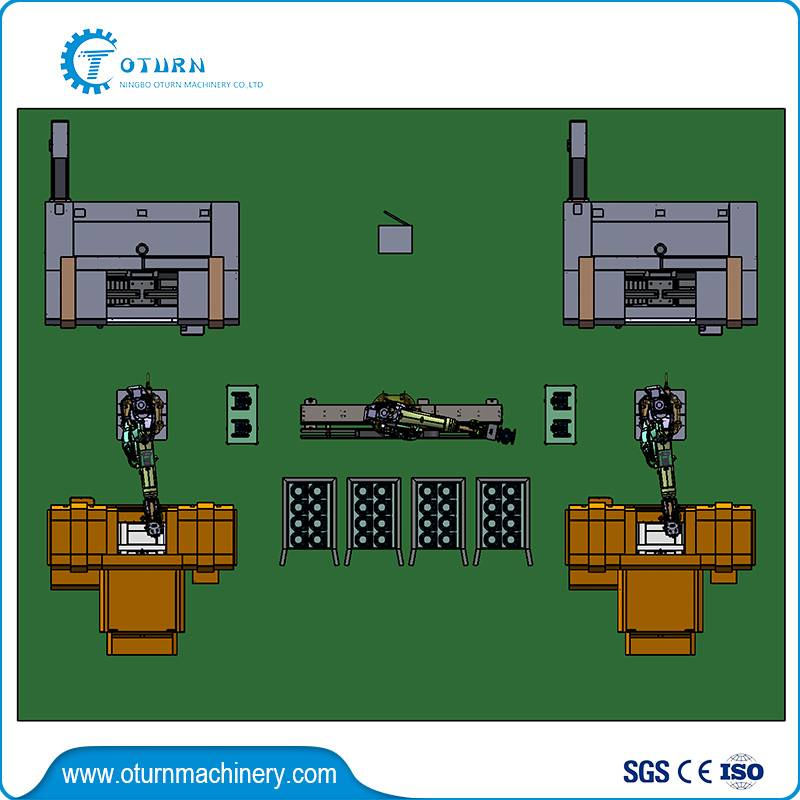

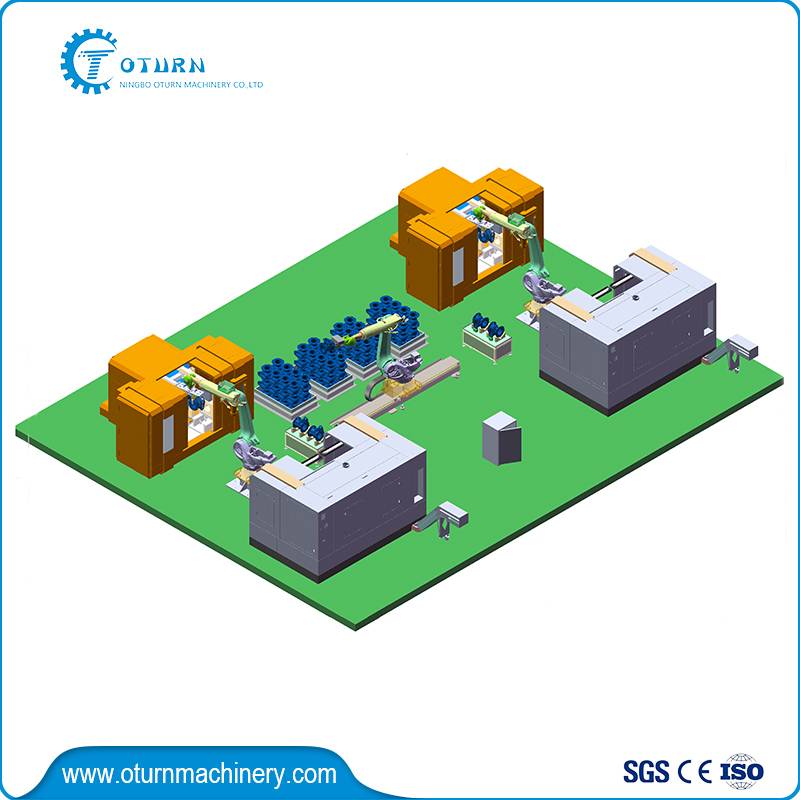

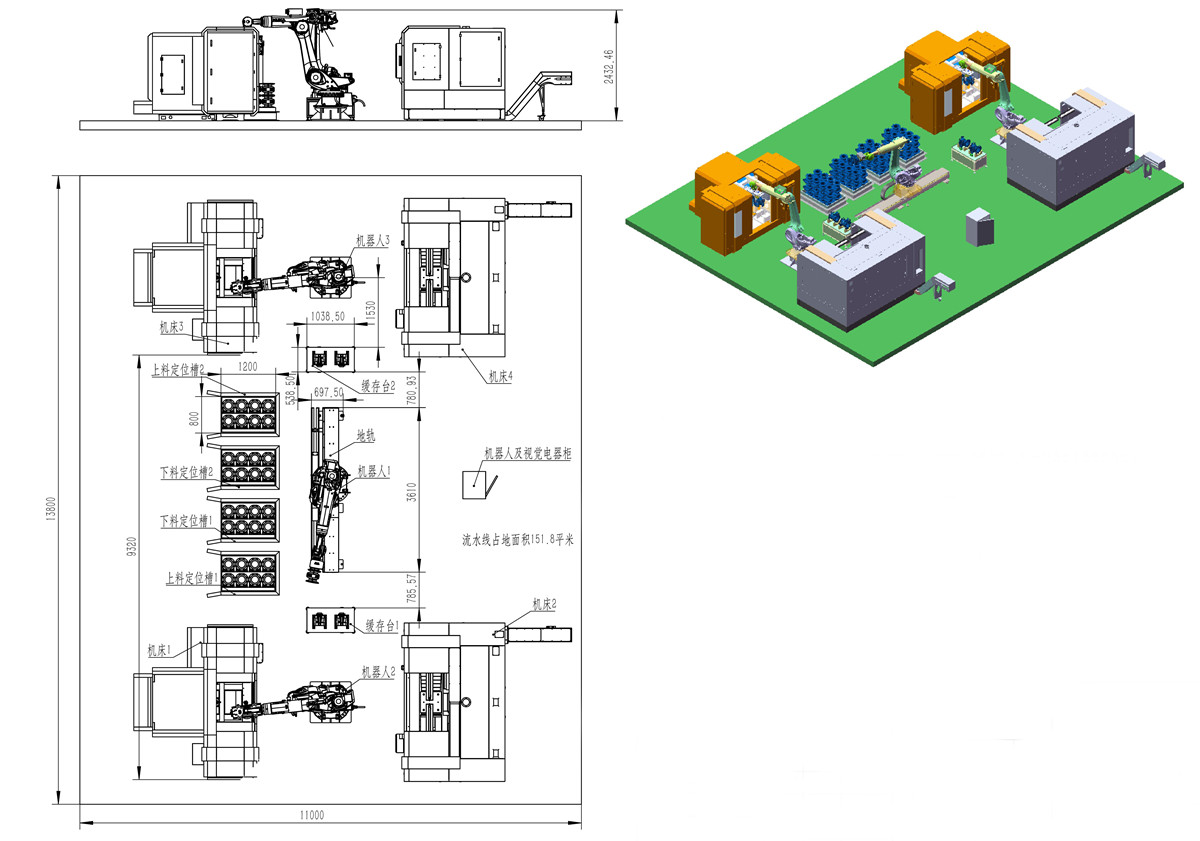

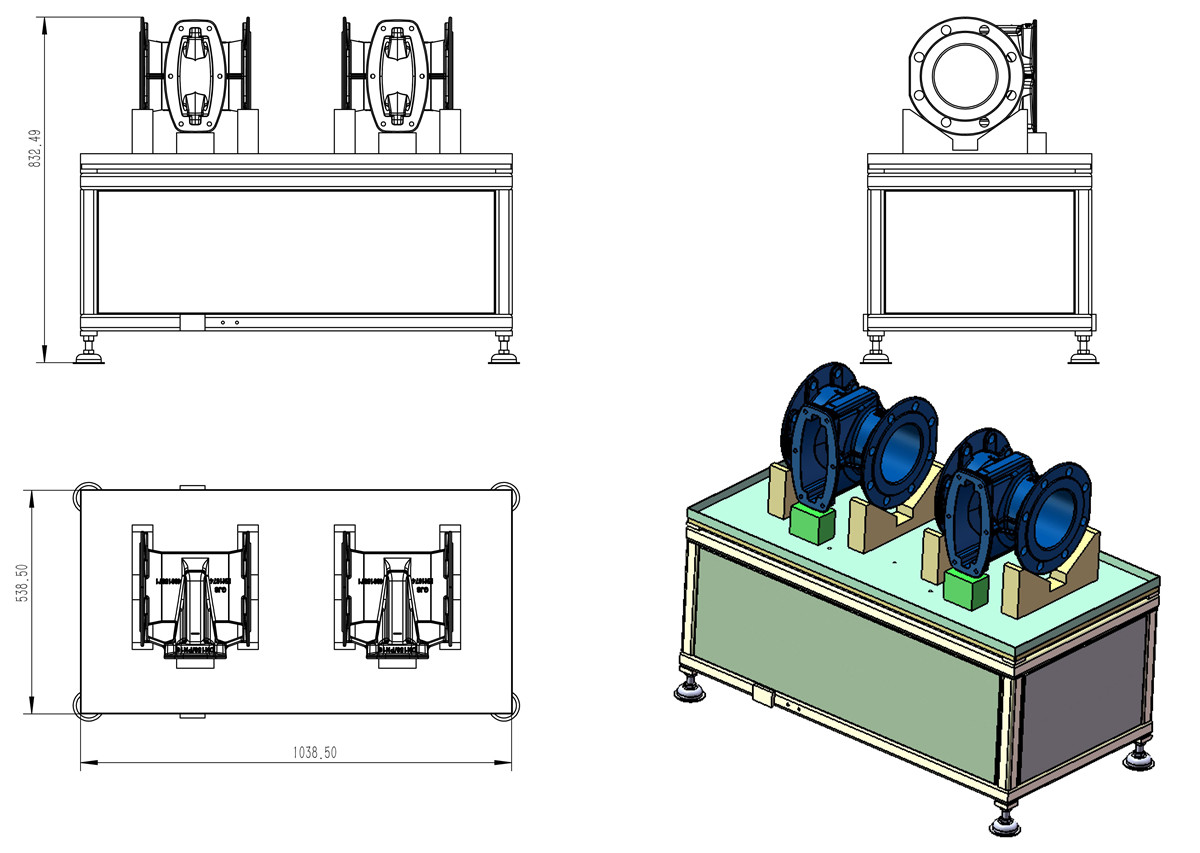

1.The operator places the pallet full of valve body workpieces in the loading positioning slot 1 and the loading positioning slot 2 for positioning, and places the empty tray in the loading positioning slot 1 and the unloading positioning slot 2 for positioning.

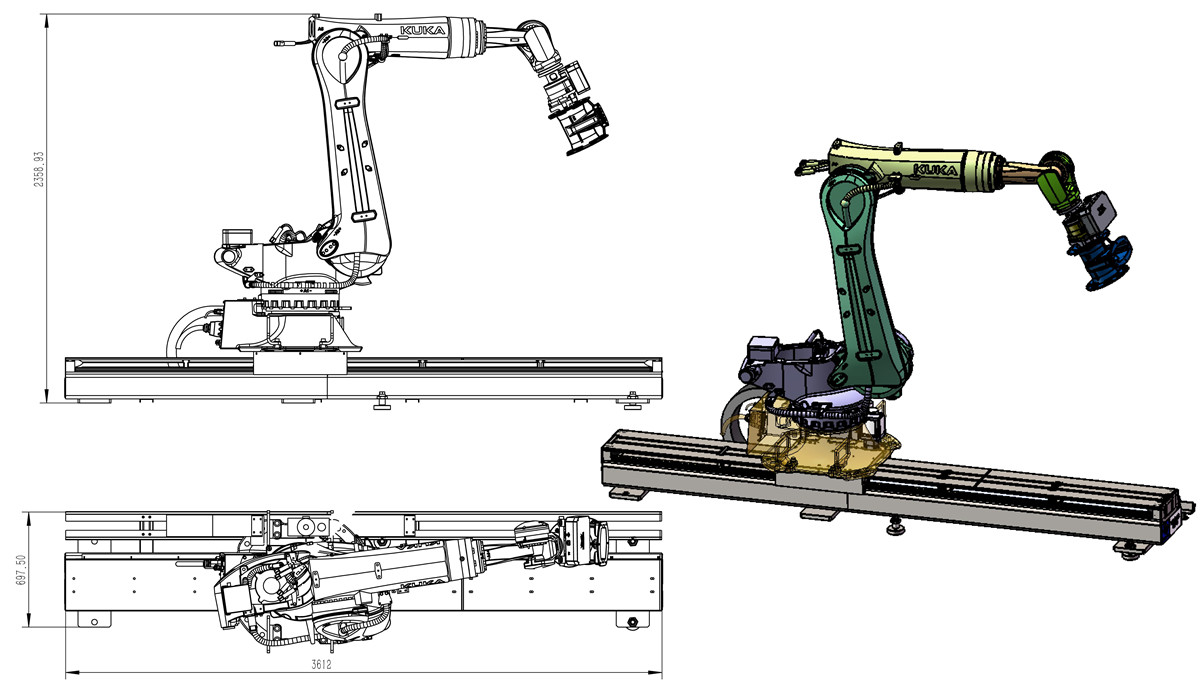

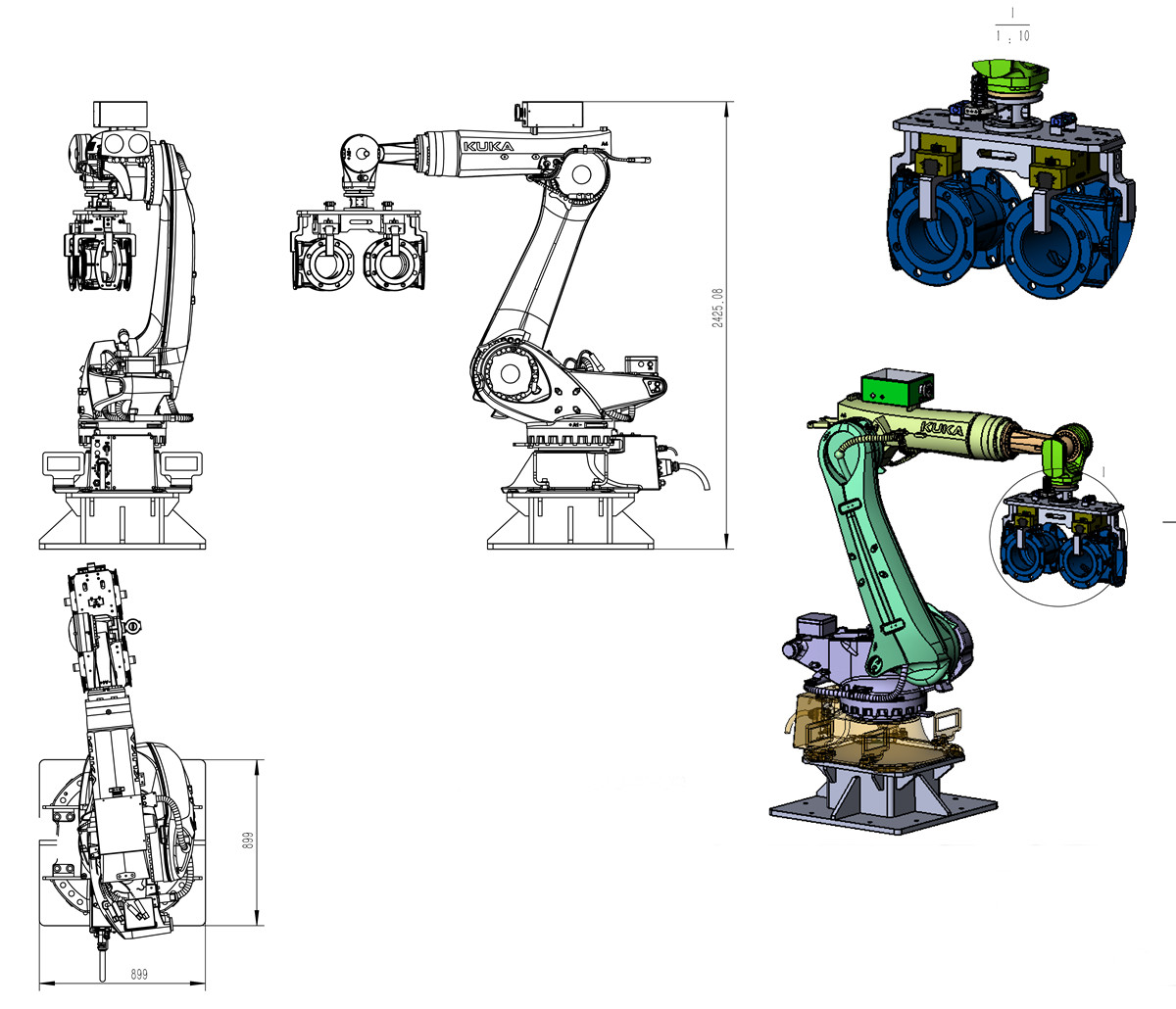

2.The camera on the robot 1 scans the workpiece on the pallet in the feeding positioning slot 1 to accurately position the workpiece, and the workpiece 1 is clamped and placed in the positioning fixture on the buffer table 1.

At the same time, it grips the processed workpiece 3 (the robot 2 has just gripped it from the machine tool 2), moves to the unloading positioning slot 1 and places it neatly in the pallet as required.

The camera on the robot 1 scans the workpiece on the pallet in the feeding positioning slot 2 to accurately position the workpiece, and the workpiece 4 is clamped and placed in the positioning fixture on the buffer table 2.

At the same time, it grips the processed workpiece 6 (the robot 3 has just gripped it from the machine tool 4), moves to the unloading positioning slot 2 and places it neatly in the pallet as required.

3.The robot 2 clamps the workpiece 1 from the buffer table 1 and runs to the machine tool 1, grips the finished workpiece 2 and clamps the workpiece 1, runs to the machine tool 2, grips the finished workpiece 3 and clamps the workpiece 2, and runs to the buffer table 1. Place the workpiece 3. Robot 2 completes the cycle.

4.The robot 3 grips the workpiece 4 from the buffering table 2 and runs to the machine tool 3, grips the finished workpiece 5 and clamps the workpiece 4, runs to the machine tool 4, grips the finished workpiece 6 and clamps the workpiece 5, and runs to the buffer table 2. Place the workpiece 6. Robot 3 completes the cycle.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.