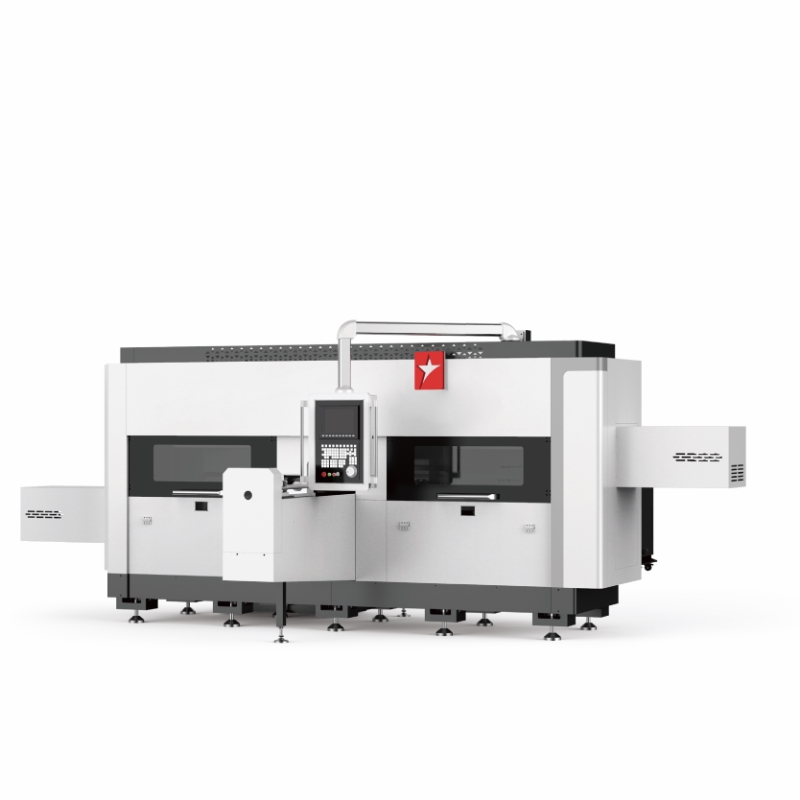

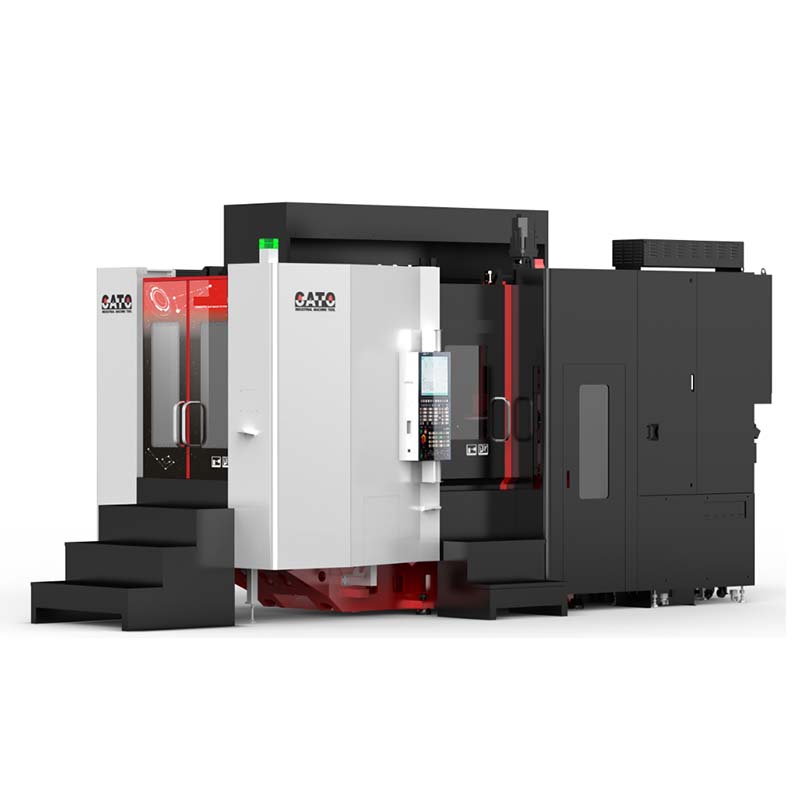

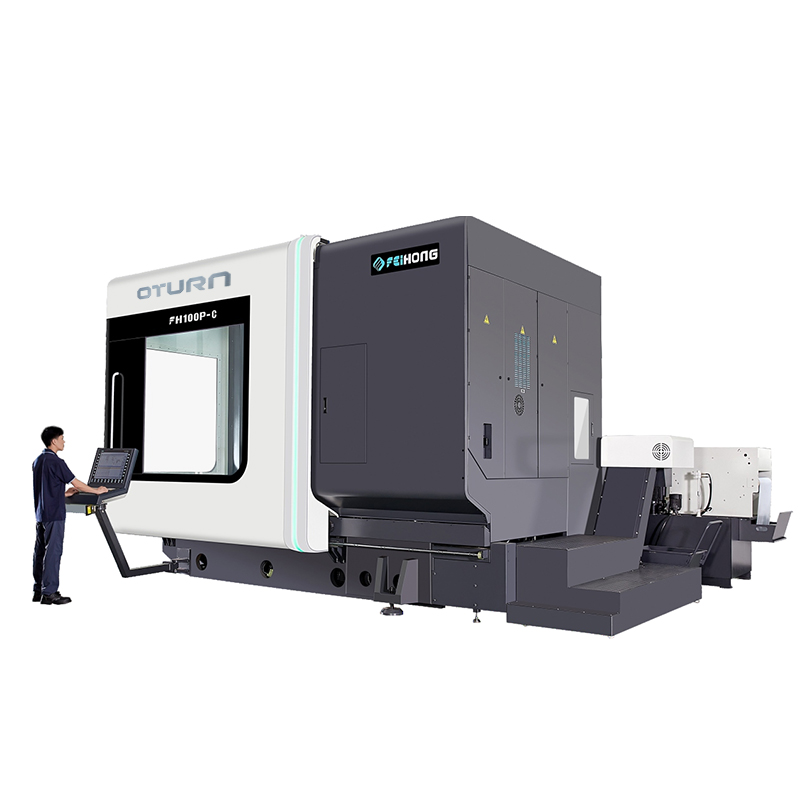

Top China Manufacturer of Special Valve Machining Machines

Are you searching for a reliable solution to enhance your valve machining projects? Our Special Valve Machining Machine is designed to meet the specific needs of manufacturers like you in China. With our advanced technology, we ensure precision and efficiency, allowing you to produce high-quality valves that meet stringent industry standards. I understand how vital it is to have the right tools for your manufacturing needs. This machine not only streamlines production processes but also reduces material waste, ultimately saving you time and money. The user-friendly interface makes it easy to operate, even for those new to valve machining. Choosing our Special Valve Machining Machine means you're investing in durability and performance that can adapt to your high-volume production demands. Let’s elevate your manufacturing capabilities and build strong, long-lasting partnerships in the industry together. Contact us today to learn more about this outstanding machine and how it can benefit your operations.

Special Valve Machining Machine Service Backed by Expertise From Concept to Delivery

In the dynamic world of industrial manufacturing, optimizing production processes is essential for achieving efficiency and innovation. The precision and performance of valve machining directly impact the overall quality of the final product. Our specialized valve machining services encompass everything from concept development to final delivery, ensuring that each component meets stringent performance specifications. With a team of seasoned experts equipped with advanced technology, we tailor our machining solutions to meet the unique needs of global clients. Whether it's designing custom valves or re-engineering existing models, we prioritize quality and precision at every stage. Our commitment to excellence is backed by years of industry experience, allowing us to navigate complex machining challenges and deliver reliable components that enhance operational performance. Collaborating with us means gaining access to cutting-edge solutions that not only facilitate seamless production but also foster innovation. We emphasize transparency and communication throughout the process, providing clients with comprehensive support to ensure their specific requirements are met. Trust in our expertise to transform your machining needs into reality, from initial concept to on-time delivery.

Special Valve Machining Machine Service Backed by Expertise From Concept to Delivery

| Service Phase | Description | Key Activities | Expertise Areas | Timeline |

|---|---|---|---|---|

| Concept Development | Initial discussion to define requirements and specifications. | Requirement analysis, feasibility study. | Mechanical engineering, product design. | 2 Weeks |

| Design Engineering | Creating detailed design and CAD models. | 3D modeling, simulation. | CAD software, stress analysis. | 4 Weeks |

| Prototyping | Building a prototype to validate the design. | Prototype fabrication, testing. | Materials science, machining. | 3 Weeks |

| Production Planning | Outlining the production workflow and resource allocation. | Process mapping, resource scheduling. | Operational management, lean manufacturing. | 2 Weeks |

| Manufacturing | Full-scale production of the valves. | Machining, assembly, quality control. | Precision machining, quality assurance. | 6 Weeks |

| Delivery and Support | Final delivery to the client with ongoing support. | Logistics management, after-sales service. | Customer service, technical support. | Ongoing |

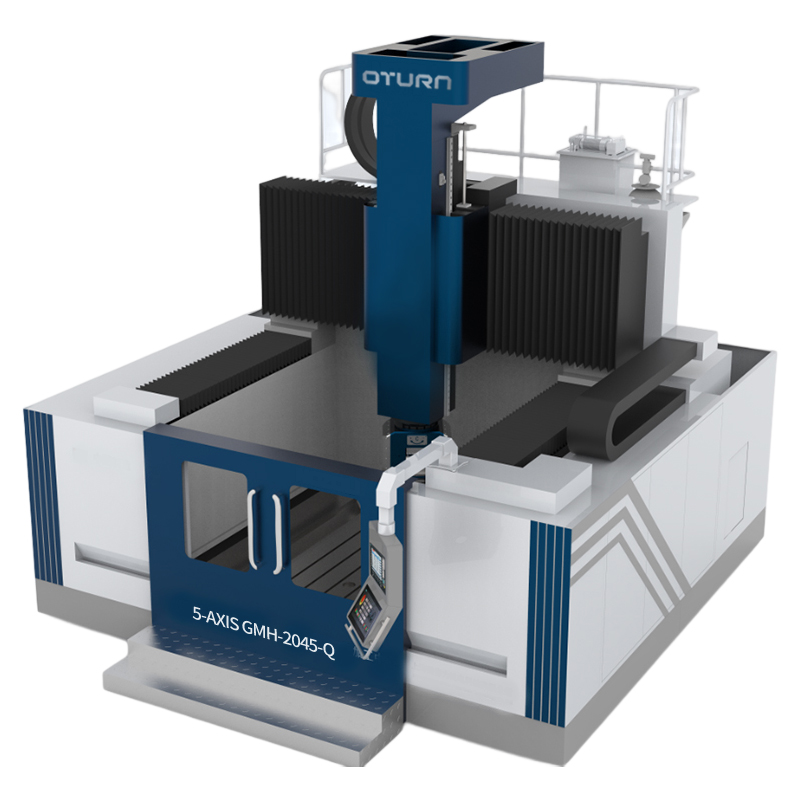

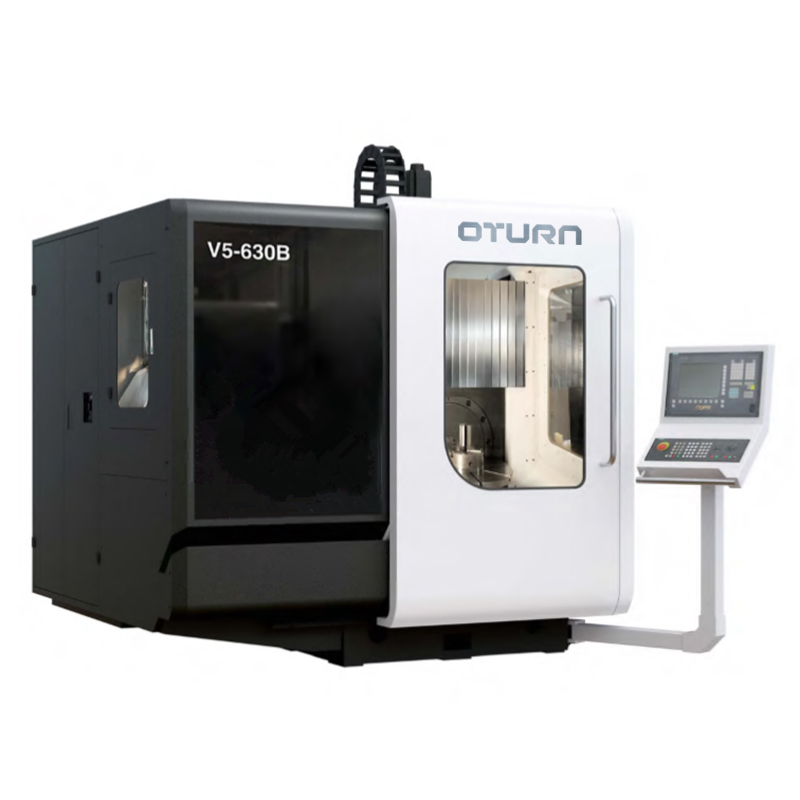

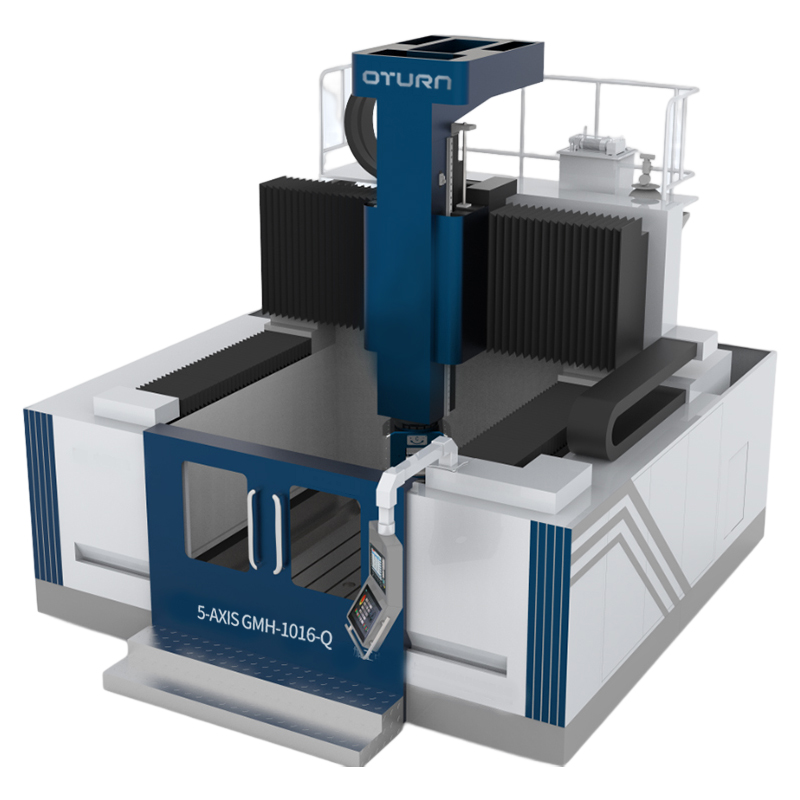

Related Products