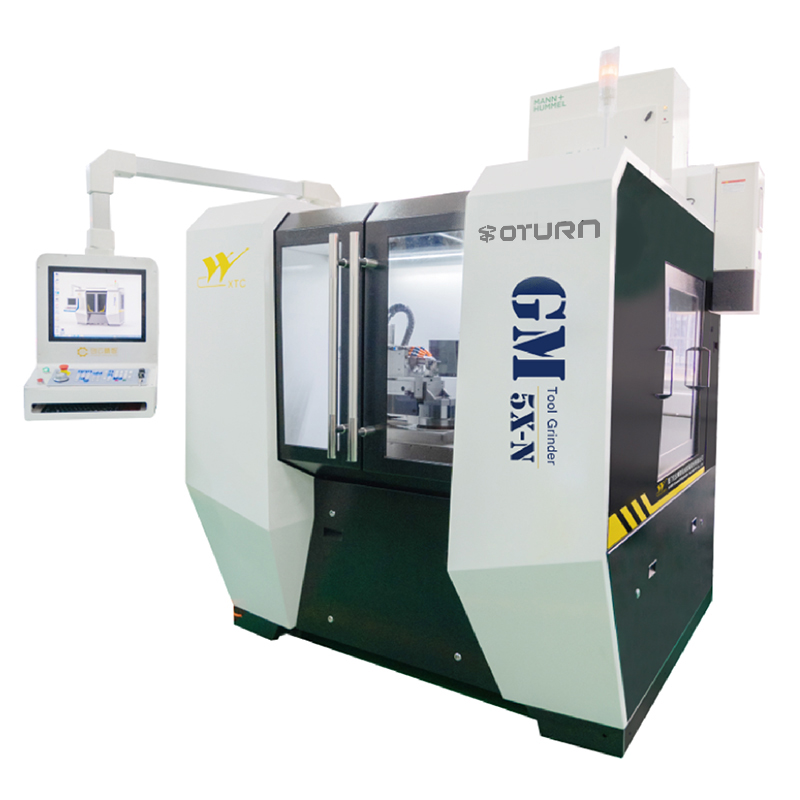

Top China Manufacturer of Lathes and Mills for Precision Engineering

As a manufacturer based in China, I understand the importance of precision in machining. Our lathes and mills are designed to meet the high demands of modern manufacturing. With advanced technology and robust construction, our machines guarantee accuracy and efficiency, making them ideal for various industrial applications. I pride myself on the quality and reliability of our equipment, ensuring that every product undergoes rigorous testing before it reaches you. These lathes and mills not only enhance productivity but also offer ease of use, which can significantly reduce downtime in your operations. When you choose us as your supplier, you’re getting more than just machines; you’re getting a commitment to customer satisfaction and ongoing support. Our competitive pricing and tailored solutions cater to your unique business needs, making it easier for you to achieve your goals. Let’s work together to elevate your manufacturing capabilities with our exceptional lathes and mills.

Lathes And Mills Sets the Industry Standard Winning in 2025

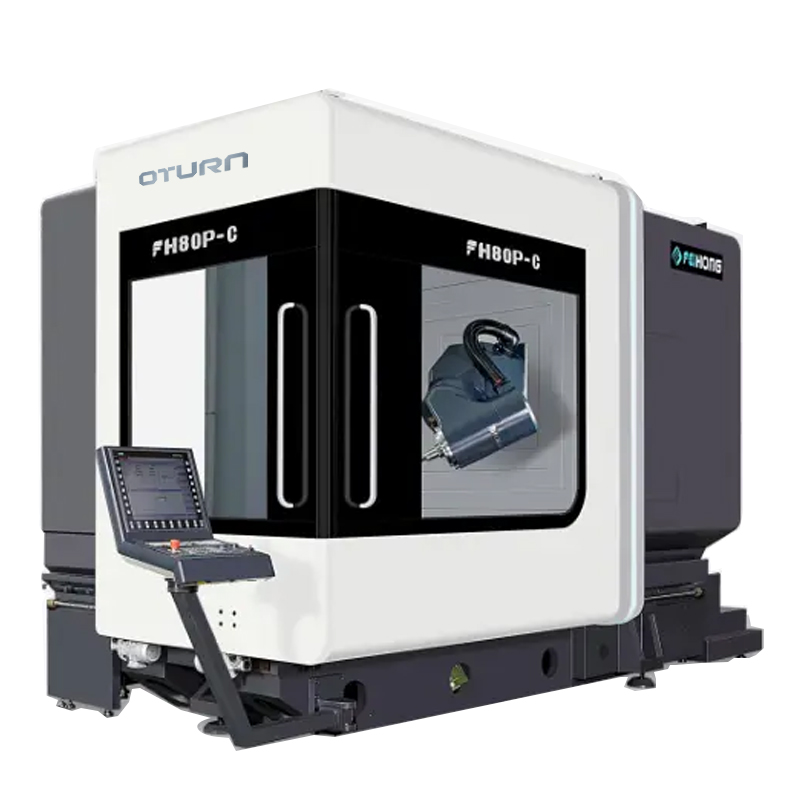

In the fast-evolving landscape of manufacturing, precision and efficiency are paramount. As we look ahead to 2025, the integration of advanced lathe and mill technologies is setting a new industry standard, redefining what it means to win in a competitive environment. These cutting-edge machines not only enhance production capabilities but also ensure greater accuracy and reduced downtime, critical factors for global procurement buyers seeking reliable partners. Investing in sophisticated machining solutions allows businesses to respond dynamically to market demands. The ability to customize and optimize production processes means that manufacturers can produce high-quality components rapidly and cost-effectively. With the ongoing shift towards automation and smart manufacturing, companies equipped with state-of-the-art lathe and mill sets will be well-positioned to lead the industry, offering procurement managers confidence in their supply chain reliability and product excellence. As we approach 2025, enterprises must embrace these technological advancements to maintain a competitive edge. The synergy between traditional craftsmanship and modern innovation not only promises better performance but also sustainability in manufacturing processes. For global buyers, aligning with forward-thinking partners who invest in quality machining equipment will be essential in navigating the challenges and opportunities that lie ahead.

Lathes And Mills Sets the Industry Standard Winning in 2025

| Machine Type | Max Speed (RPM) | Cutting Capacity (mm) | Power (kW) | Applications |

|---|---|---|---|---|

| CNC Lathe | 3000 | 500 | 7.5 | Metal Turning |

| Vertical Mill | 4000 | 400 | 5.5 | Milling Operations |

| Horizontal Mill | 3500 | 600 | 10 | Heavy Cutting |

| CNC Router | 24000 | 200 | 4 | Woodworking |

| Swiss Type Lathe | 6000 | 300 | 3 | Precision Parts |

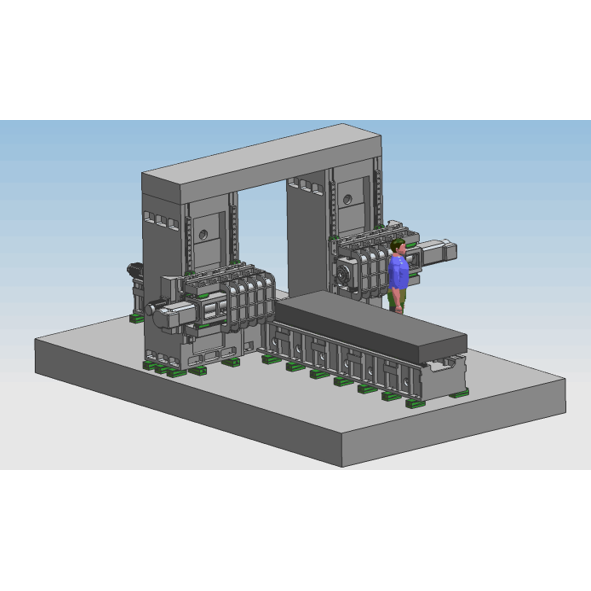

Related Products