Top China Manufacturer for Quality Lathe Turning Solutions

When searching for high-quality lathe turning products, I know how important it is to partner with a reliable manufacturer in China. Our lathe turning services provide precision and quality that meet diverse industry needs. With advanced machinery and skilled technicians, we create custom parts tailored specifically for your projects. I’ve seen firsthand how our commitment to excellence helps businesses achieve their goals faster and more efficiently. Whether you need small-scale prototypes or large production runs, I can assure you of our consistency in delivering timely results. Working with a Chinese manufacturer means you’ll benefit from competitive pricing without compromising quality. Let’s connect and explore how our lathe turning solutions can elevate your operations, improve your product offerings, and drive your business forward. You won’t be disappointed with the level of dedication we bring to every project.

Lathe Turning Dominates Guarantees Peak Performance

In the realm of precision manufacturing, lathe turning has emerged as a critical process that guarantees peak performance for various applications. The art of lathe turning involves removing material from a rotating workpiece, enabling the production of complex shapes and high tolerances that are essential in industries ranging from automotive to aerospace. By leveraging advanced technology and skilled craftsmanship, manufacturers can ensure that every component meets stringent quality standards while optimizing production efficiency. One of the key advantages of lathe turning lies in its versatility. It accommodates a wide variety of materials, including metals, plastics, and composites, making it suitable for diverse projects. Furthermore, the adaptability of lathe turning allows for both small-batch manufacturing and large-scale production runs, offering global procurement partners the flexibility they need to meet their specific demands. With the integration of state-of-the-art CNC technology, manufacturers can achieve remarkable precision and repeatability, further elevating their commitment to delivering high-quality products. As the global market continues to evolve, the importance of reliable, high-performance manufacturing processes like lathe turning cannot be overstated. Organizations seeking to enhance their product lines or streamline their supply chains can benefit significantly from collaborating with skilled manufacturers that prioritize cutting-edge techniques and uncompromising quality. Embracing lathe turning not only ensures exceptional performance but also positions businesses ahead of the curve in an increasingly competitive landscape.

Lathe Turning Dominates Guarantees Peak Performance

| Process Type | Material Used | Spindle Speed (RPM) | Cutting Tool Type | Surface Finish (Ra) | Cycle Time (min) |

|---|---|---|---|---|---|

| Turning | Aluminum | 1200 | Carbide | 0.8 | 5 |

| Facing | Steel | 800 | HSS | 1.2 | 4 |

| Grooving | Brass | 1500 | Ceramic | 0.5 | 3 |

| Threading | Titanium | 600 | Insert | 1.0 | 6 |

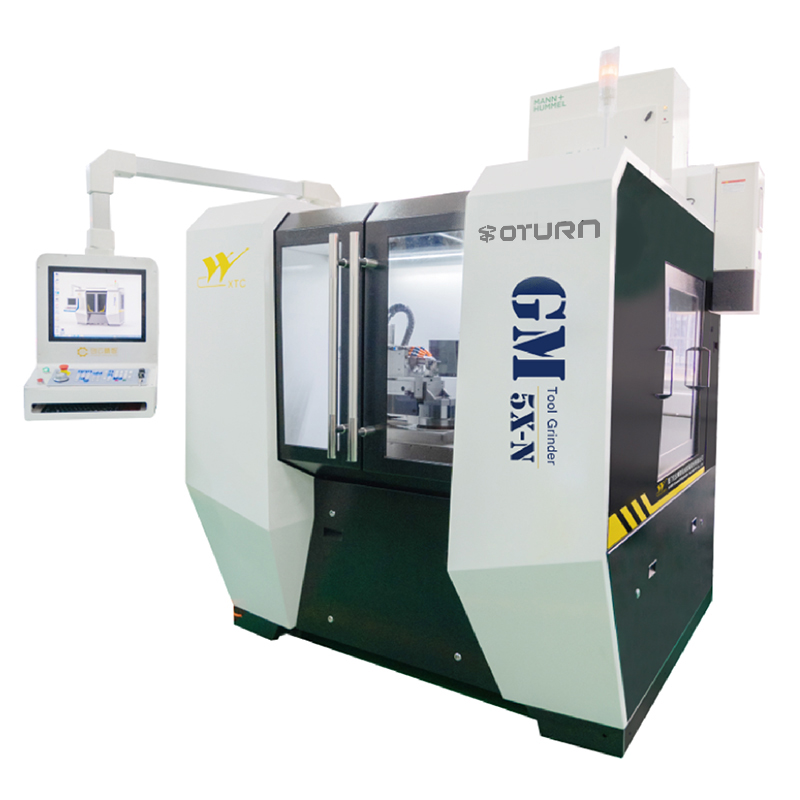

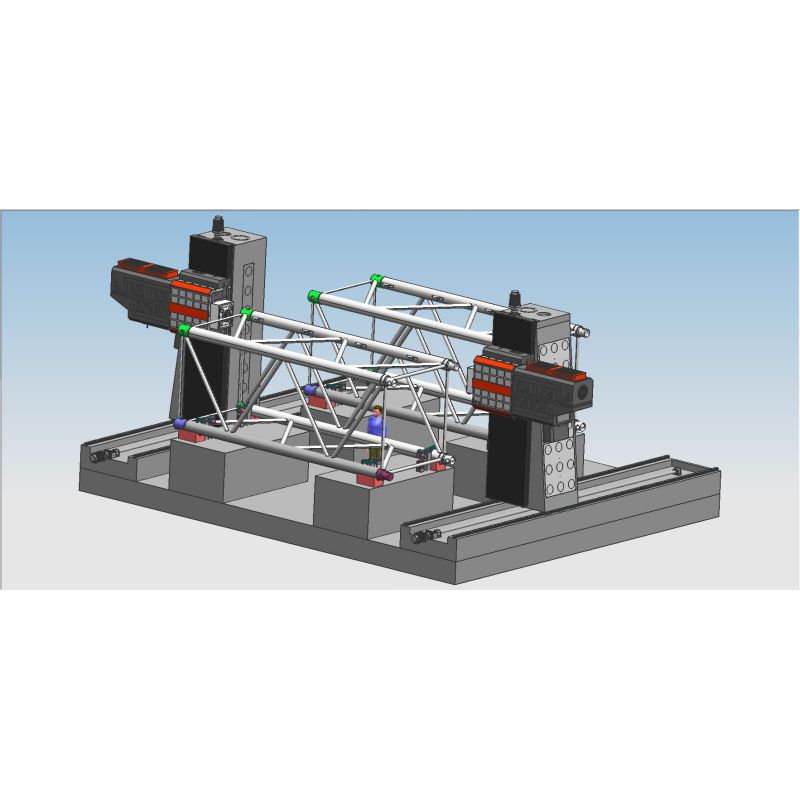

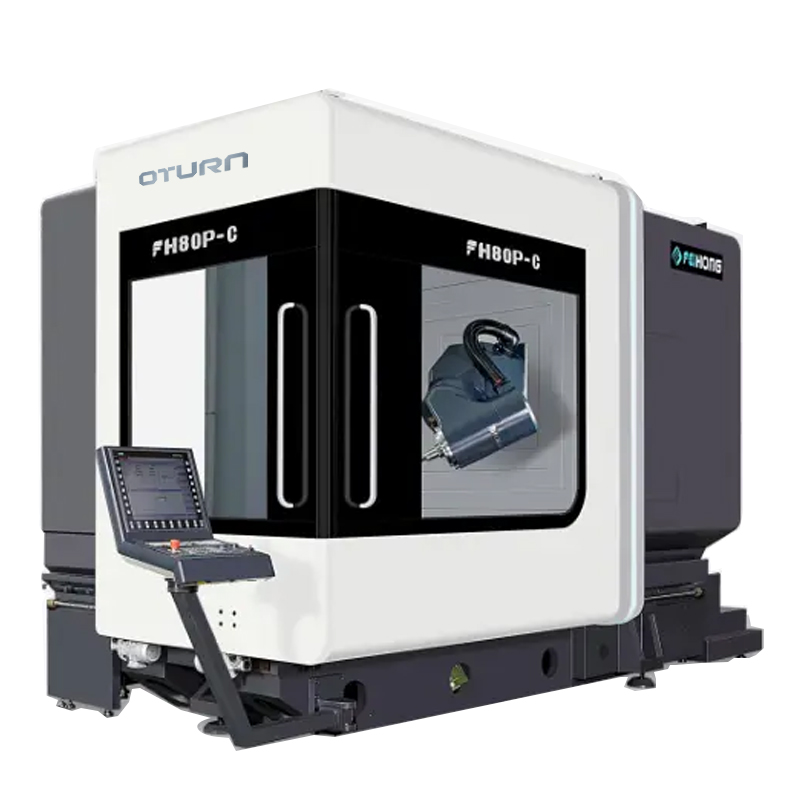

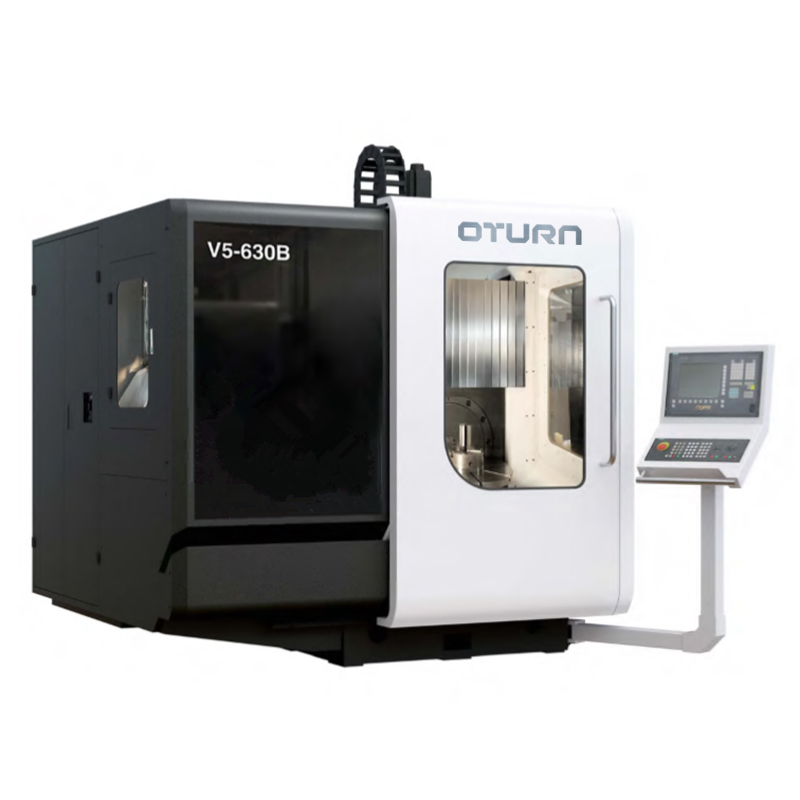

Related Products